Passively steerable module axle

A technology of modular shaft and steering shaft, applied in steering mechanism, steering rod, vehicle parts, etc., can solve the problem of increasing the total load and achieve the effect of avoiding additional weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

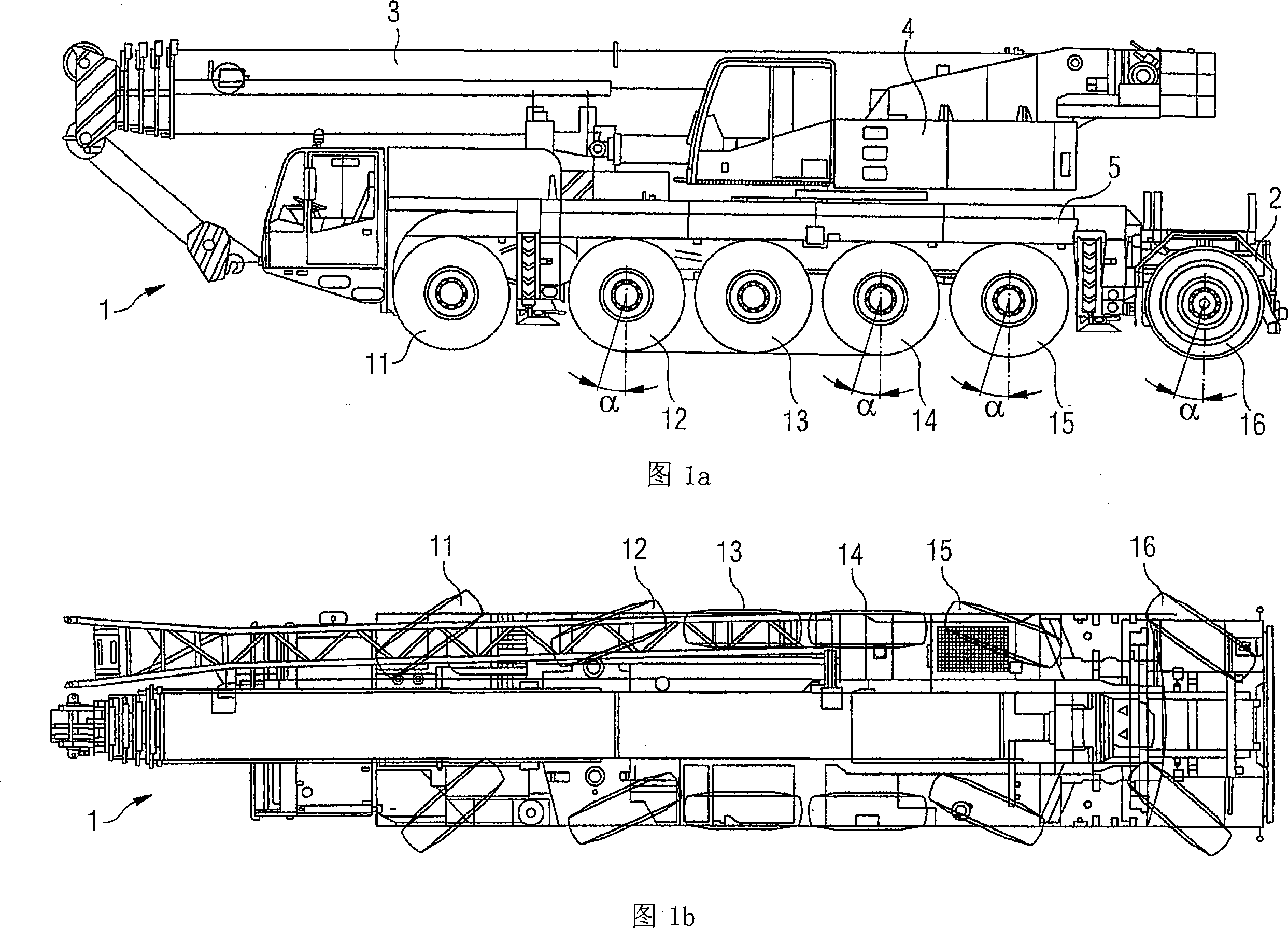

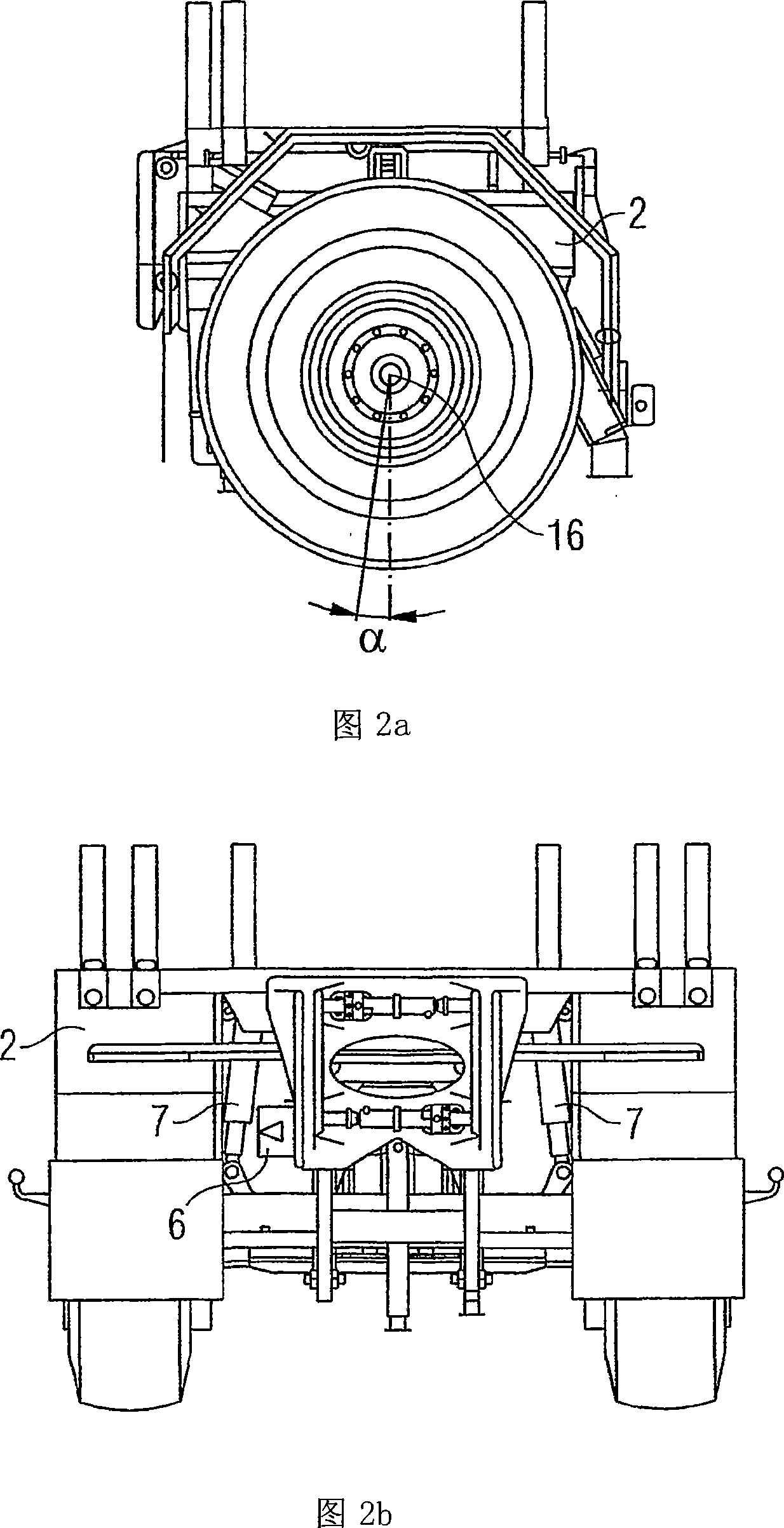

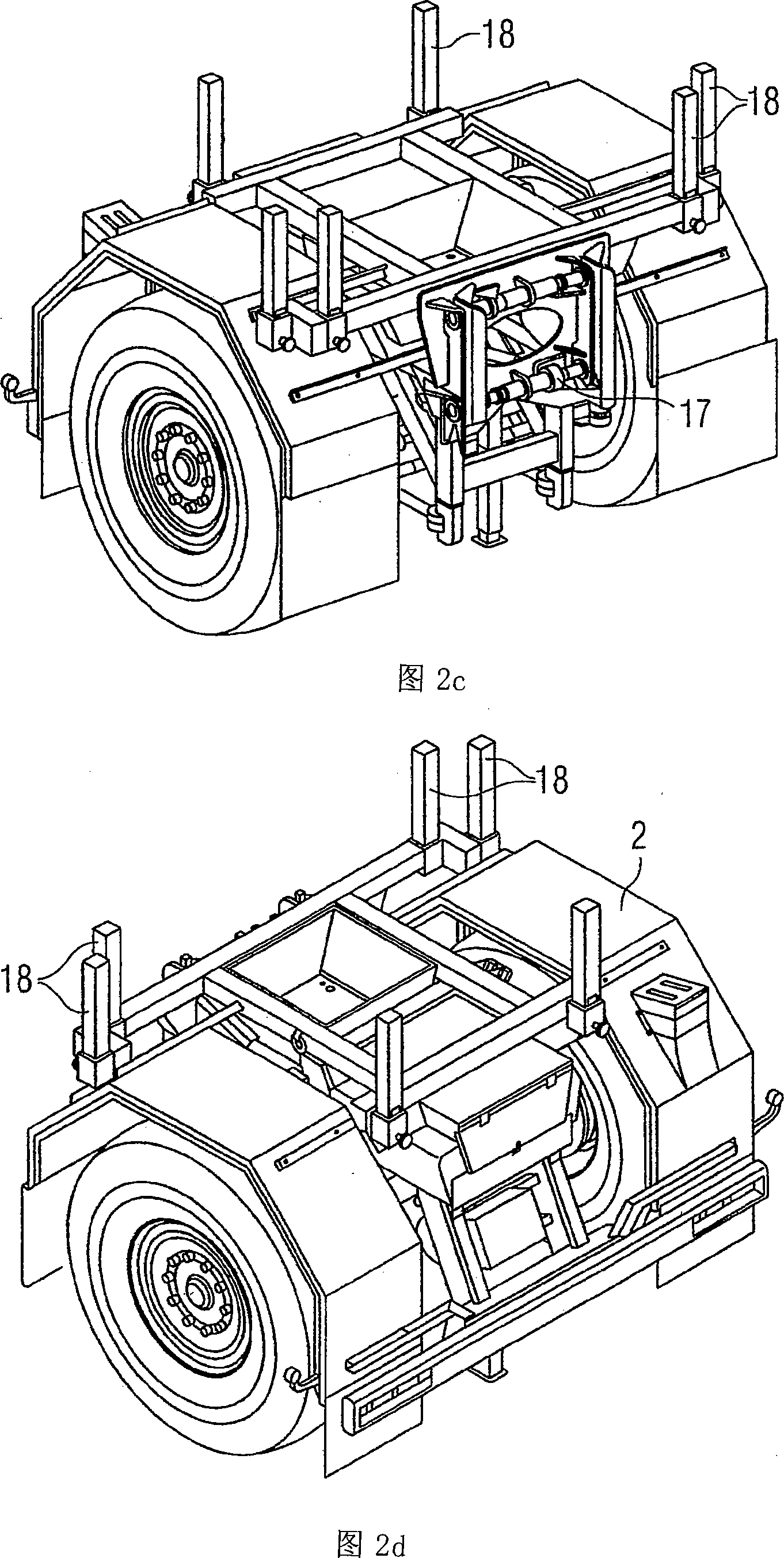

[0041] As shown in the side view Fig. 1a and the top view Fig. 1b, the lifting vehicle of the present invention comprises a chassis 5, and the transmission mechanism of the chassis has 5 shafts 11, 12, 13, 14, 15, wherein only the first shaft 11, the second The shaft 12, the fourth shaft 14 and the fifth shaft 15 are steerable, while the shaft 13 is in the form of a rigid shaft. A rotatable superstructure 4 with a telescopic arm 3 , which is here telescopically retracted, is arranged on the chassis 5 of the lift truck 1 . The modular shaft 2 of the present invention is also detachably mounted on the rear of the chassis 4, and the shaft 16 of the modular shaft 2 here is also steerable. By mounting the module shaft 2 on the rear of the chassis 5, the unit formed together by the chassis 5 and the module shaft 2 can also be regarded as the chassis of the lift truck 1, in particular here the shaft 16 of the module shaft 2 is also suitable for steerable.

[0042] The steerable axl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap