Blade for a single-blade vacuum pump

A vacuum pump and single vane technology, which is applied in the direction of pumps, pump components, rotary piston pumps, etc., can solve the problems of high power consumption of vacuum pumps, and achieve the effects of low power consumption, reduced weight and simple assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

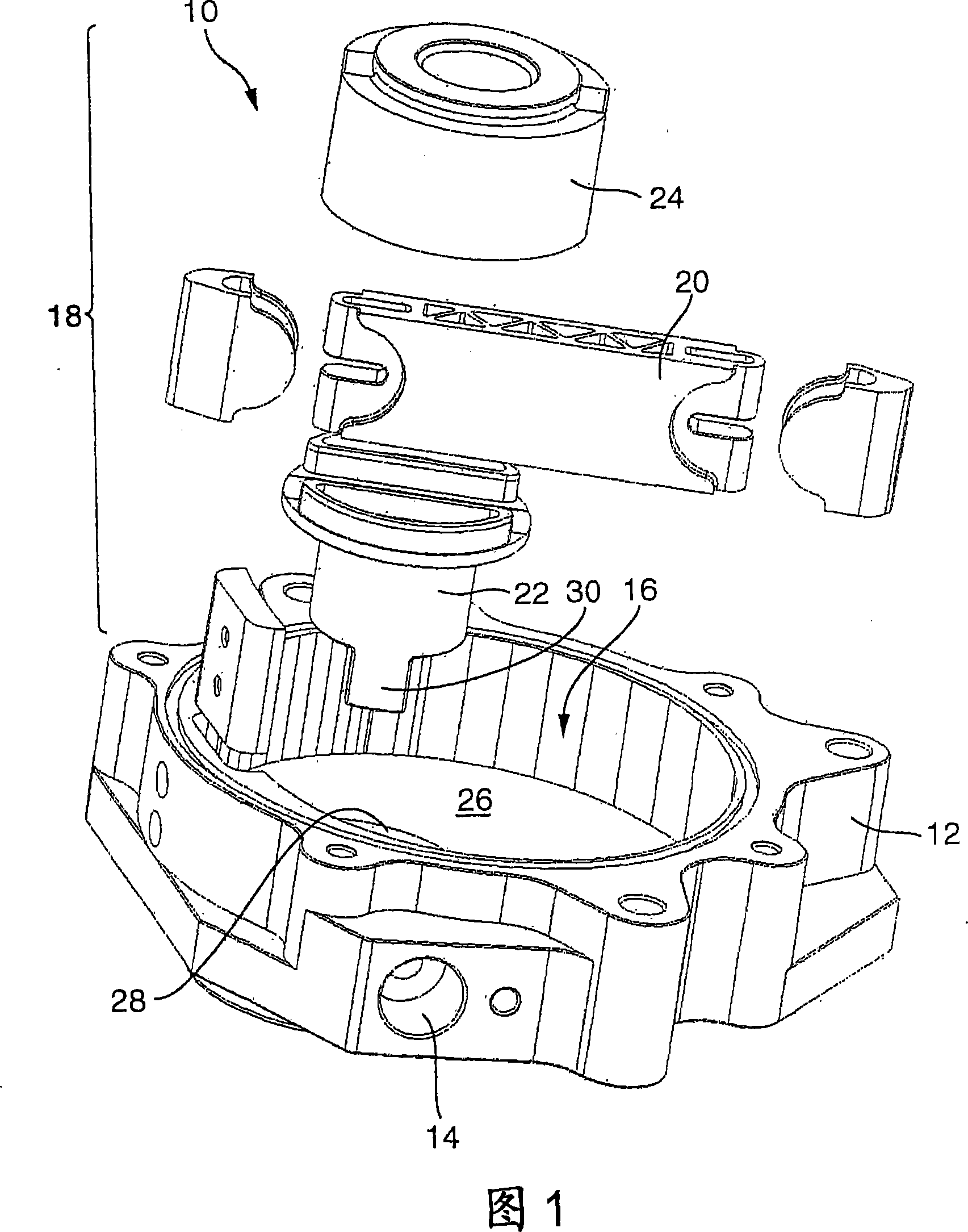

[0019] The vacuum pump as a whole is designated by the reference numeral 10 in FIG. 1 , the housing 12 being shown without a housing cover. The housing 12 has a suction connection 14 which opens into an interior 16 . In this interior space 16 is located a rotor, indicated as a whole by 18 , in which rotor blades 20 are mounted displaceably perpendicular to the axis of rotation 21 . The rotor 18 is composed of two parts and has a rotor shaft 22 and a rotor housing 24 . The rotor shaft 22 penetrates the joint housing 12, in particular through the drive opening 28 through the bottom 26 of the joint interior chamber 18, and a rectangular section 30 protrudes from the housing 12 at the rear, by means of which (by means of a drive not shown) the The rotor shaft turns. The drive opening 28 is provided with a suitable sealant so that lubricant cannot escape from the interior 16 and air and / or dirt cannot enter the interior 16 .

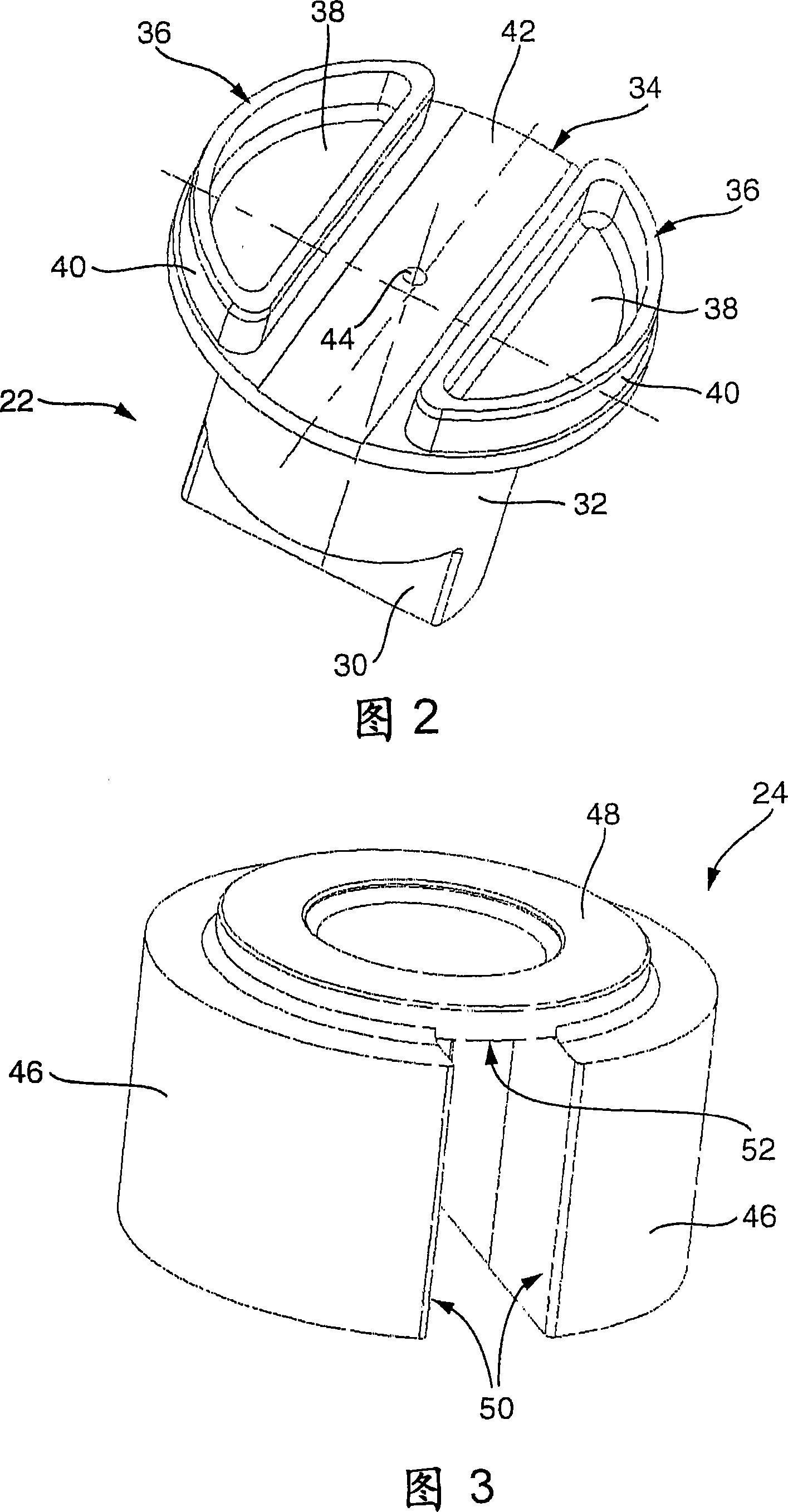

[0020] As can be seen from FIG. 2 , segment 30 exten...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap