Dental grinding stone with axis and its production method

A manufacturing method and a grinding stone technology, which are applied in the fields of dentistry, dental tools, medical science, etc., can solve the problems of difficult to grind fine parts, poor convenience of use, low grinding ability, etc., and achieve the effect of good sharpness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention will be described below with reference to the drawings.

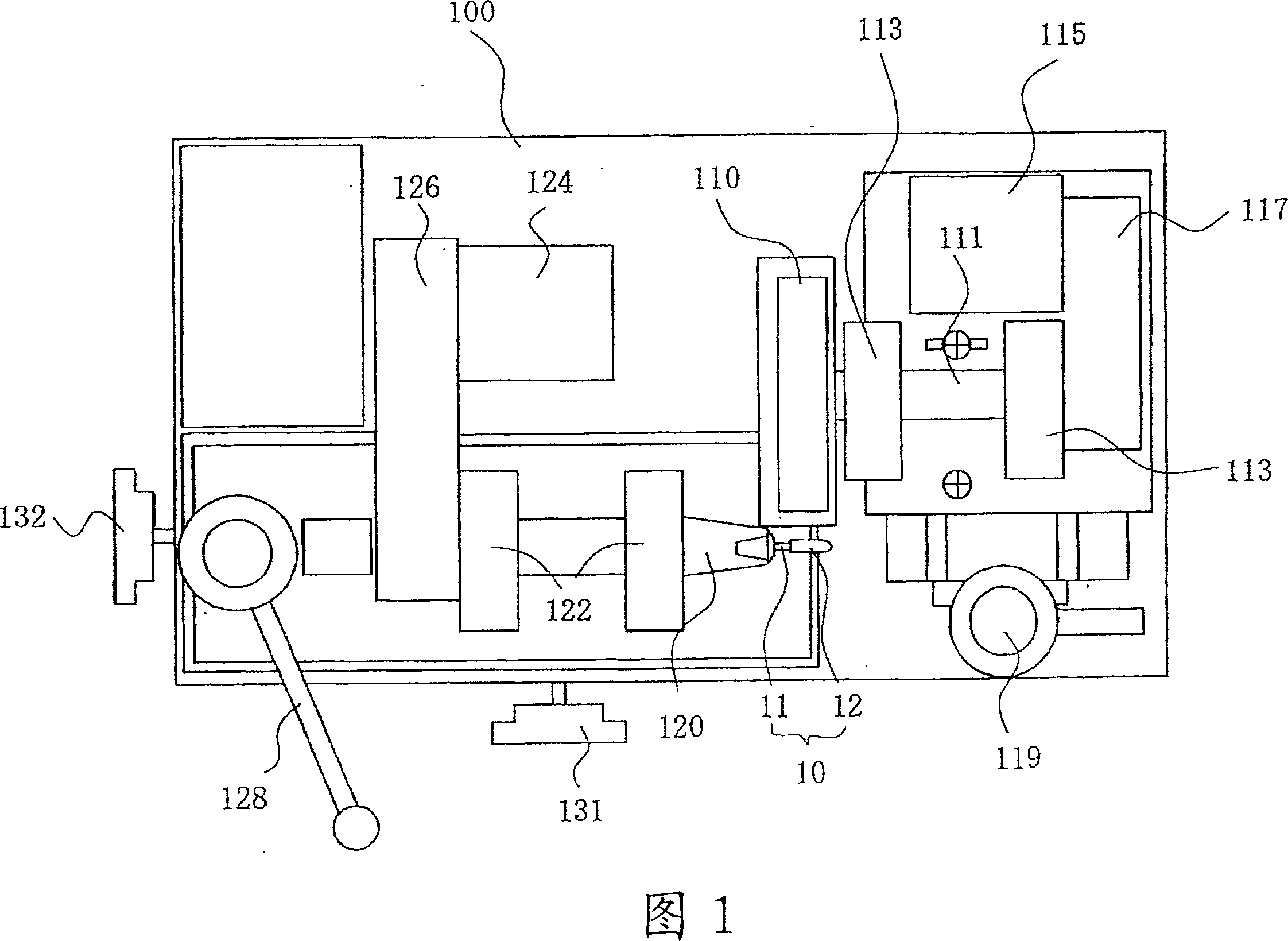

[0021] FIG. 1 is a plan view schematically showing a polishing apparatus of the present invention. The grinding device 100 shown in this figure has a rotating grindstone 110 slightly to the right of the center of the figure. The rotary grindstone 110 is a shaped grindstone (that is, a grindstone having the same grinding surface as the surface of the workpiece), and has a grinding surface shaped to conform to the shape of the grindstone 12 of the dental grindstone with shaft 10 . The rotating grindstone 110 is attached to the front end of a rotating shaft 111 , and both ends of the rotating shaft 111 are supported by bearings 113 , 113 . The rotating shaft 111 is connected to a motor 115 with a transmission device 117 such as a belt, and the rotary grindstone 110 rotates around the rotating shaft 111 . The feed handle 119 can integrally move from the motor 115 to the rotary g...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap