Combined helix baffle plate shell-and-tube heat exchanger

A shell-and-tube heat exchanger and helical baffle technology, applied in the direction of heat exchanger type, heat exchanger shell, indirect heat exchanger, etc., can solve the problem of increasing the load of power equipment and reducing the heat exchange area of the heat exchanger. , dirt deposition and other problems to avoid waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

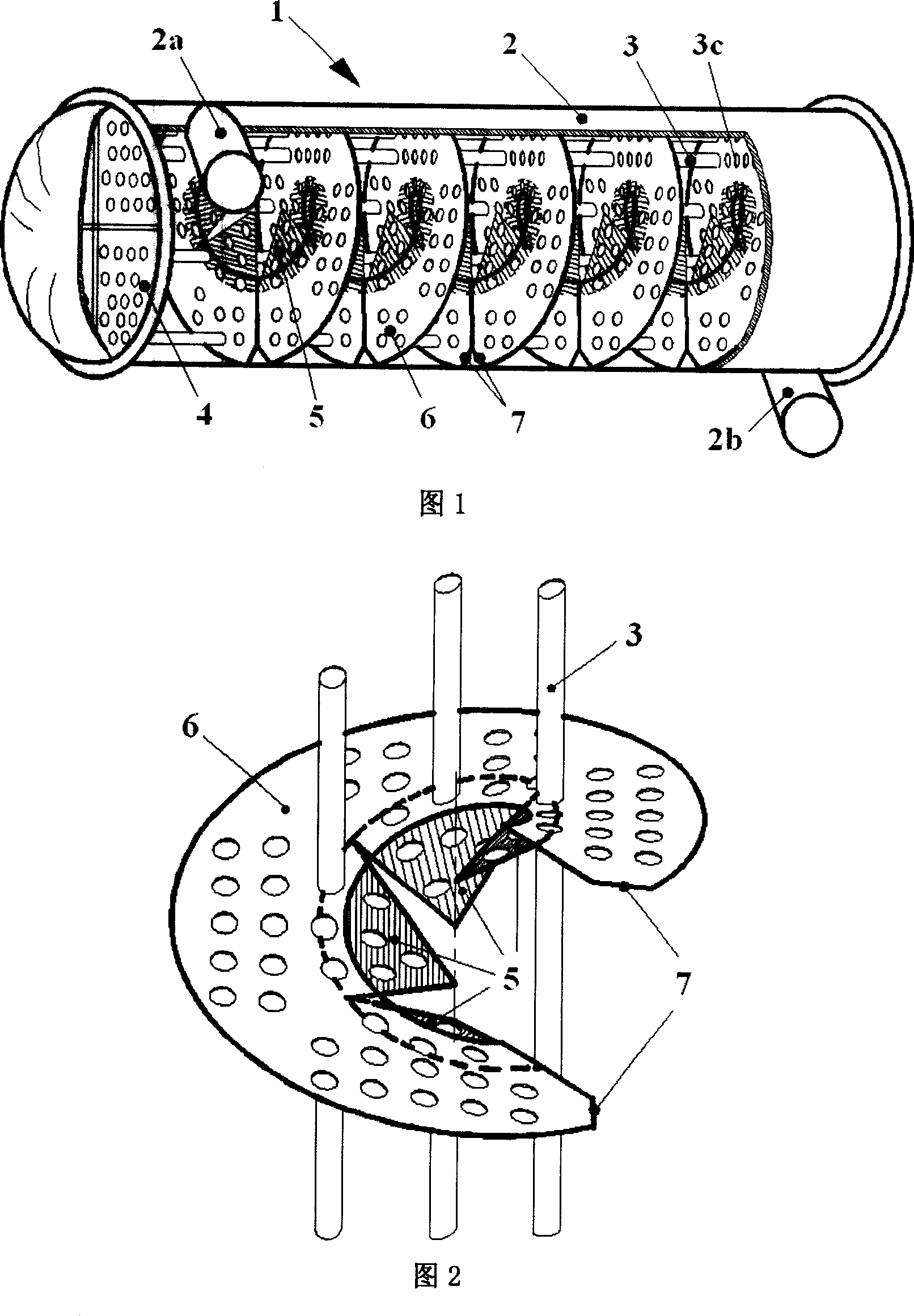

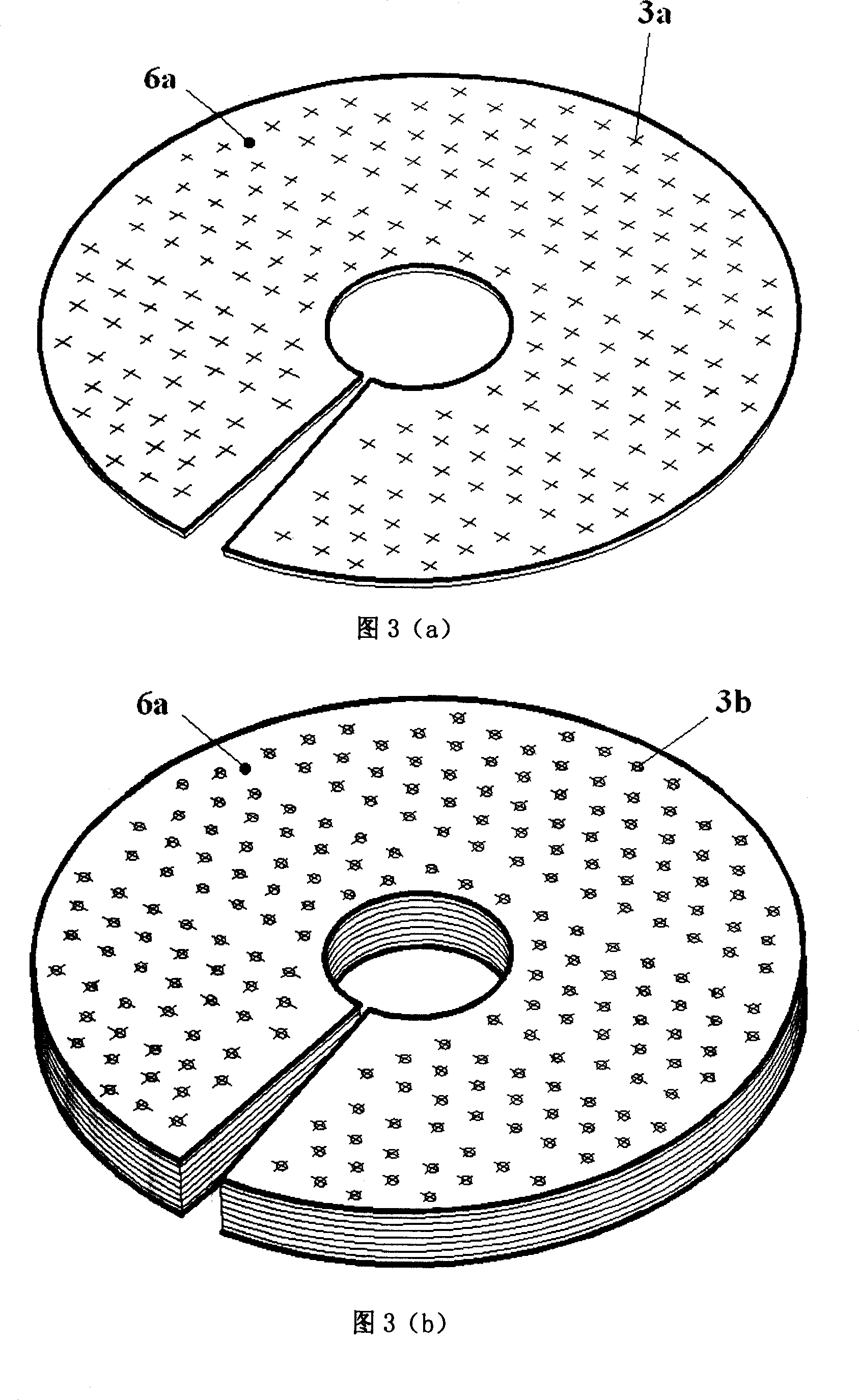

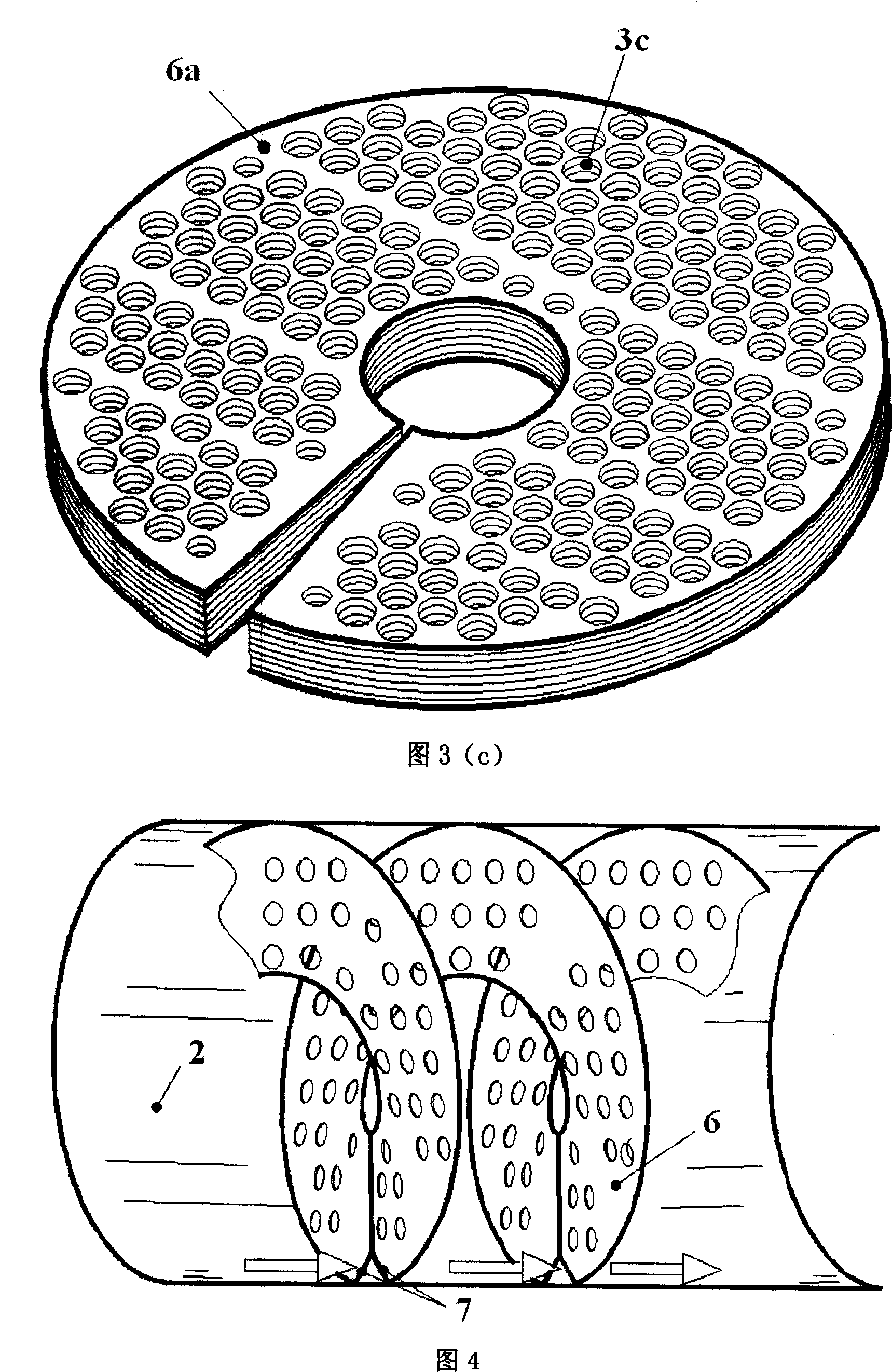

[0024] Referring to Figure 1, the combined spiral baffle shell-and-tube heat exchanger 1 of the present invention includes a shell 2, a shell-side inlet pipe 2a, a shell-side outlet pipe 2b, a heat exchange tube bundle 3, a tube sheet 4, and an inner spiral Baffle 5 and outer spiral baffle 6. The shell-side inlet pipe 2a and the shell-side outlet pipe 2b on the shell 2 adopt the form of side-in and side-out, which are installed close to the outer edge of the shell 2, and flow into and out of the shell-side space along the direction tangent to the shell, so that the The fluid on the shell side is more in line with the characteristics of spiral flow, reducing the local resistance caused by the inlet and outlet. The heat exchange tube bundle 3 is interspersed on the inner helical baffle 5 , the outer helical baffle 6 and the two tube sheets 4 located at both ends of the shell. Within each pitch, the inner helical baffle 5 is located in the inner space of the shell 2 In the centr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com