Sealed wiring harness

A sealed and wire harness technology, applied in the field of wire harnesses, can solve problems such as electromagnetic interference, aging, and easy corrosion of wires, and achieve the effects of good breakdown resistance, good anti-aging, and good shielding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

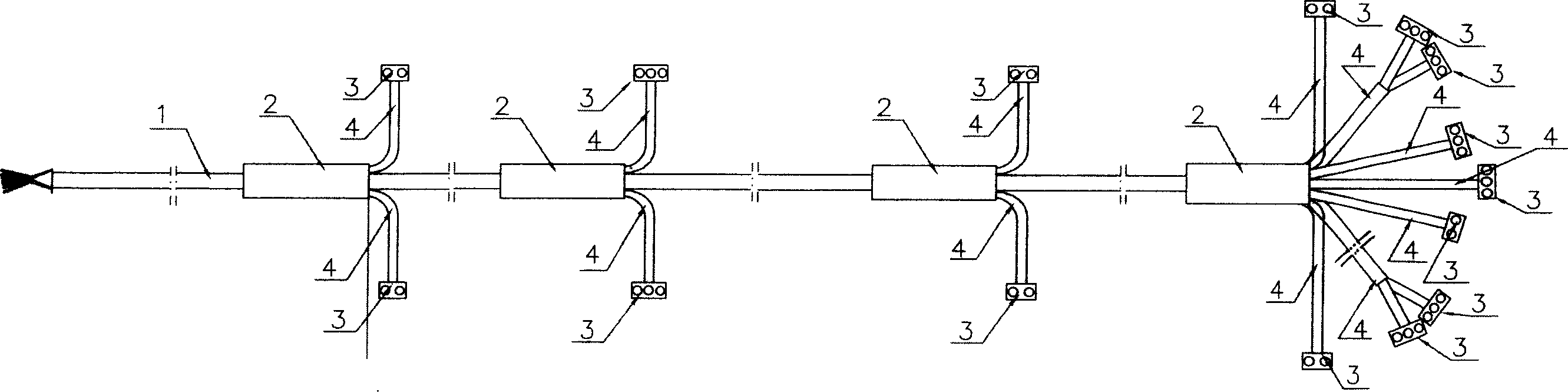

[0010] The present invention and its specific implementations will be described in further detail below in conjunction with the accompanying drawings.

[0011] Referring to the accompanying drawings, the present invention includes a main wire harness, a branch wire and an electrical connector, and is characterized in that: the connection between the main wire harness 1 and the branch wire 4 is wrapped with a sealing rod 2, and one end of the branch wire 4 and the electrical connector 3 are sealed by injection molding connection, the electrical connector 3 is a socket or a plug.

[0012] The sealing rod is a glue rod or a plastic rod.

[0013] First, at the junction of the main wire harness 1 and the branch wire 4, the main wire harness 1 is peeled off and connected with the branch wire 4 with crimping terminals according to the corresponding colors, and then placed on the injection molding machine and used to mold the main wire and the branch wire into a sealed shape. Rod 2 (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com