Steel wire tip drawing technology and apparatus

A steel wire and tipping technology, which is applied in the field of steel wire tipping technology and devices, can solve problems such as scrap loss of wire drawing dies, difficulty in threading the mold, and broken steel wires, and achieve the effects of eliminating tissue defects, easy operation, and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

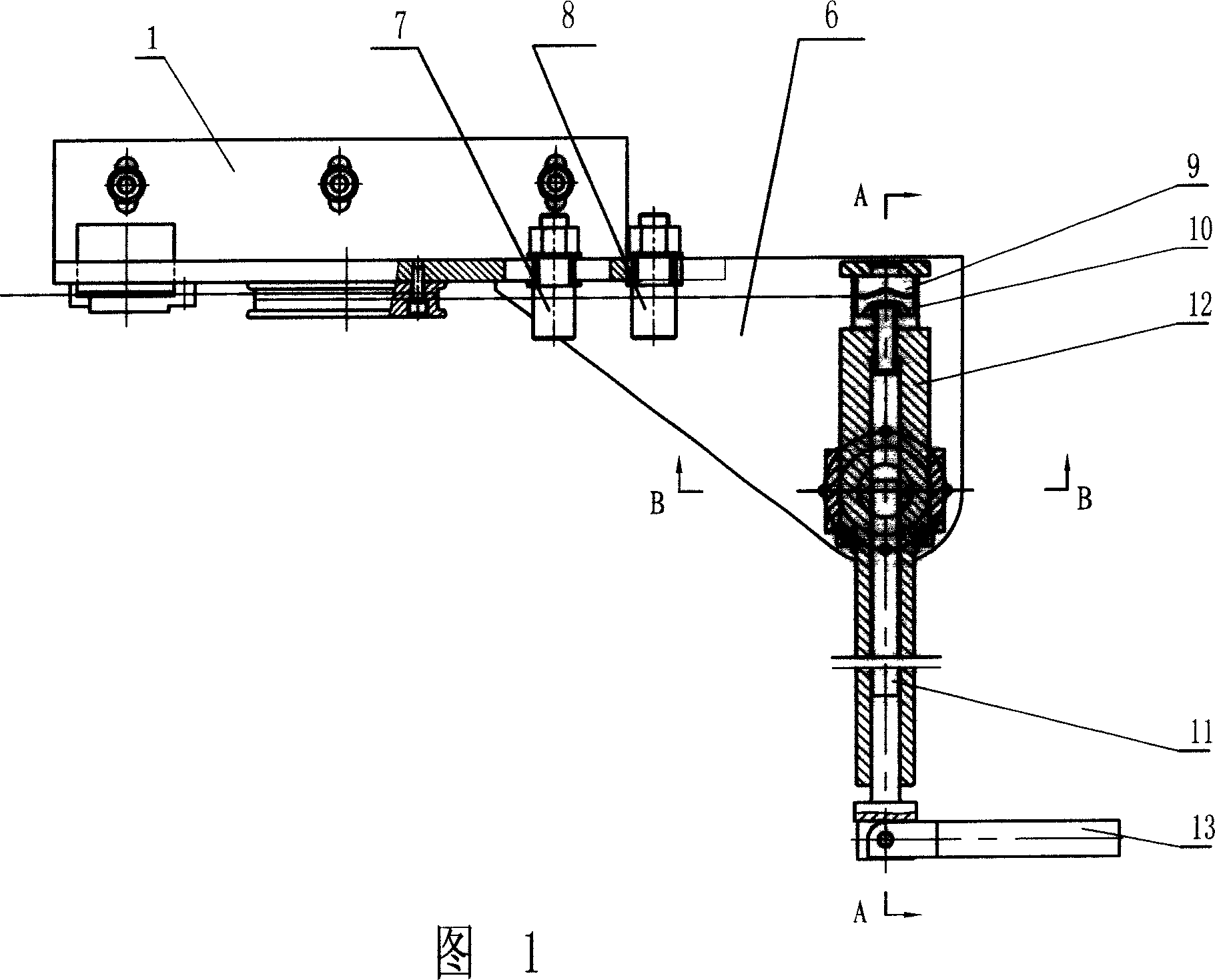

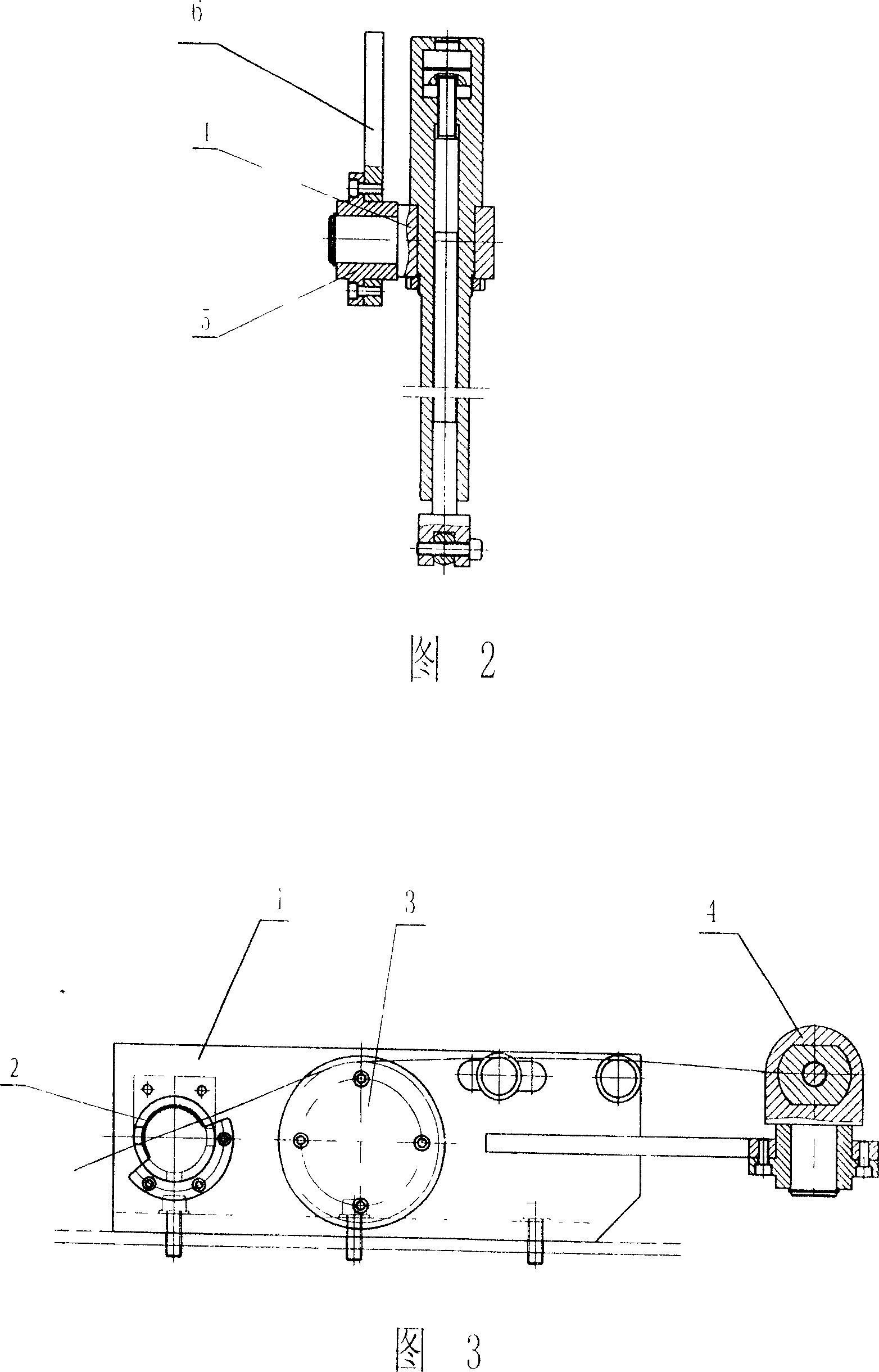

[0016] With reference to accompanying drawing, a kind of steel wire tipping device, it comprises support 1, left clamper 2, reel 3, heating device, right clamper and core seat 4, left clamper 2, reel 3, heating The device is installed on the bracket 1, and the left clamp 2 can be a pneumatic clamp. The right clamp is located in the core base 4 and can rotate around the core base 4. The core base 4 is installed on the upper part of the support 5. The support 5 is fixed on the bracket 1 through the mounting plate 6. The heating device is located between the winding wheel 3 and the right clamping between devices. The heating device includes a positive electrode rod 7 and a negative electrode rod 8. The two electrode rods are insulated from the bracket 1. The positive and negative electrode rods are connected to a low-voltage power supply, and the connection of the low-voltage power supply is controlled by a switch. The distance between the positive and negative electrode rods ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com