Dampening method of cool transfer printing and apparatus thereof

A technology of cold transfer printing and transfer printing, which is applied in transfer printing, rotary printing machines, printing of special varieties of printed matter, etc. It can solve the problems of cold transfer printing quality control and improvement difficulties, and improve the transfer rate and promote the combination , improve the effect of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Ultrasonic humidifier wetting device for cold transfer printing machine.

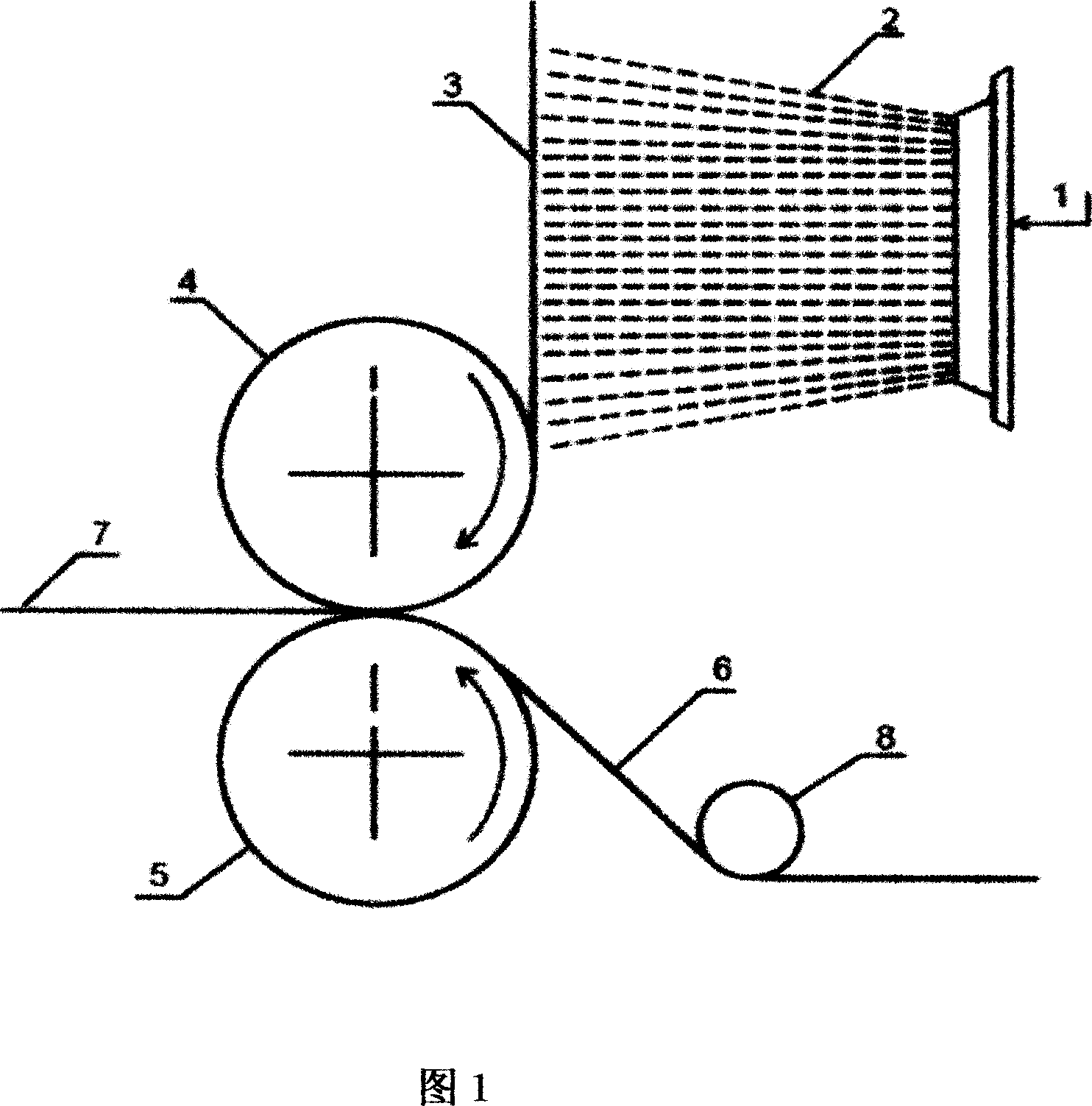

[0015] As shown in Figure 1, a wetting device is installed on the new cold transfer printing machine. There is a spray port 1 in front of the roll transfer device of the cold transfer printing machine, the spray port is a fully open spray port, fixed on the frame, the spray direction of the spray port 1 is aligned with the upper roller 4, and the upper transfer printing paper 3 advances direction of the pattern face. The spray port is equipped with a baffle, which can adjust the width of the spray port. The maximum effective spray width is 1.6m, which is the same as the effective width of the upper roll of 1.6m. The rear part of the spray port 1 is connected with the humidifier and the fan through the pipeline. The humidifier is the humidifying part of the industrial ultrasonic humidification sprayer, and the humidification capacity reaches 2kg / h, and the fan uses an axial flow fan. When the co...

Embodiment 2

[0017] Centrifugal humidifier wetting device for cold transfer printing machine.

[0018] As shown in Figure 1, a wetting device is installed on the new cold transfer printing machine. There is a spray port 1 in front of the roll transfer device of the cold transfer printing machine, and the spray port of the nozzle is installed on the mouth surface, which is fixed on the frame, and the spray direction of the spray port 1 is aligned with the transfer printing paper 3 on the upper roller 4 The pattern face for the forward direction. The spray port is equipped with a baffle, which can adjust the width of the spray port. The maximum effective spray width is 1.6m, which is the same as the effective width of the upper roll of 1.6m. The rear part of the spray port 1 is connected with a humidifier and a fan through a pipeline. The humidifier is a centrifugal humidifier with a humidification capacity of about 3kg / h, and the fan is a centrifugal fan. When the cold transfer printing m...

Embodiment 3

[0020] Evaporative humidifier wetting device for cold transfer printing machine.

[0021]As shown in Figure 1, a wetting device is installed on the new cold transfer printing machine. There is a spray port 1 before the roller transfer printing device of the cold transfer printing machine, which is fixed on the frame, and the spray direction of the spray port 1 is aligned with the pattern surface of the transfer printing paper 3 advancing direction on the upper roller 4 . The spray port is equipped with a baffle, which can adjust the width of the spray port. The maximum effective spray width is 1.8m, which is the same as the effective width of the upper roll of 1.8m. The rear part of the spray port 1 is connected to the humidifier and the fan with a hard PVC pipe. The humidifier is a JJL-004A evaporative humidifier with a humidification capacity of 2-5kg / h, and a humidity sensor is used to control the humidification capacity. When the cold transfer printing machine is working,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com