Driving device for crank arm type sewing mechine

A driving device, sewing machine technology, applied in sewing machine control devices, sewing machine components, sewing equipment and other directions, can solve the problems of high cost, complex structure, many types of parts, etc., and achieve the effect of preventing misoperation accidents and shortening the shaft length.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

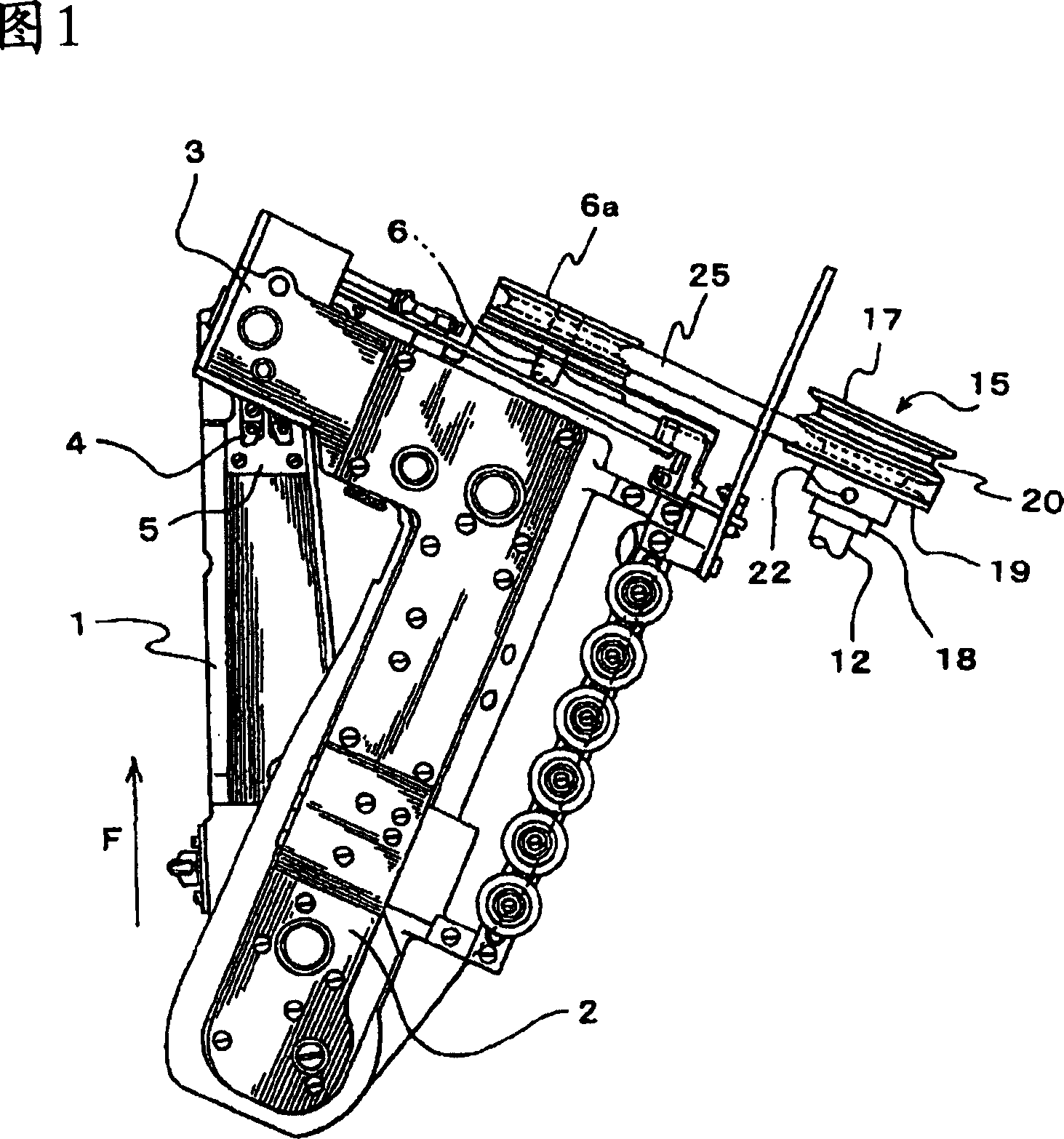

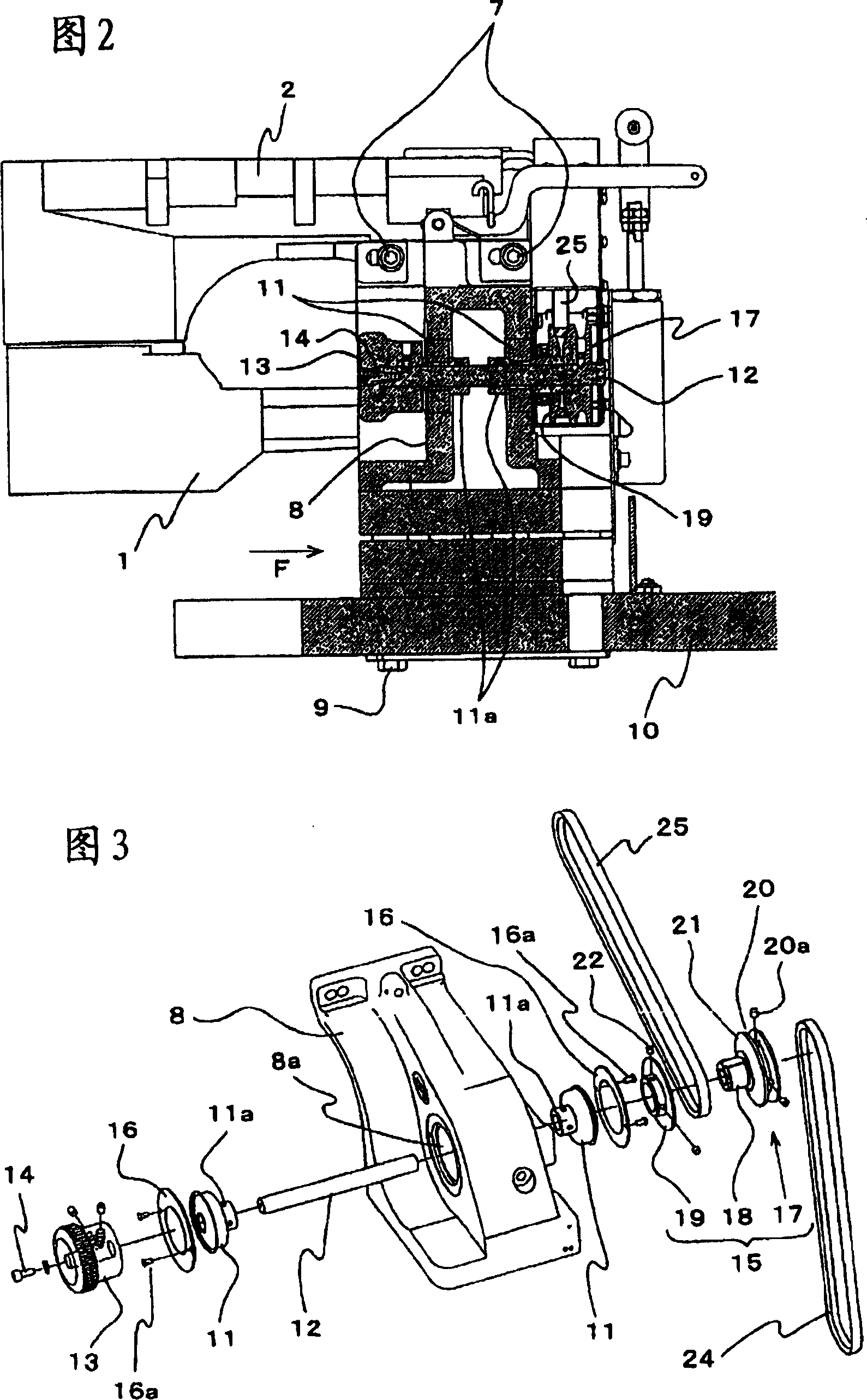

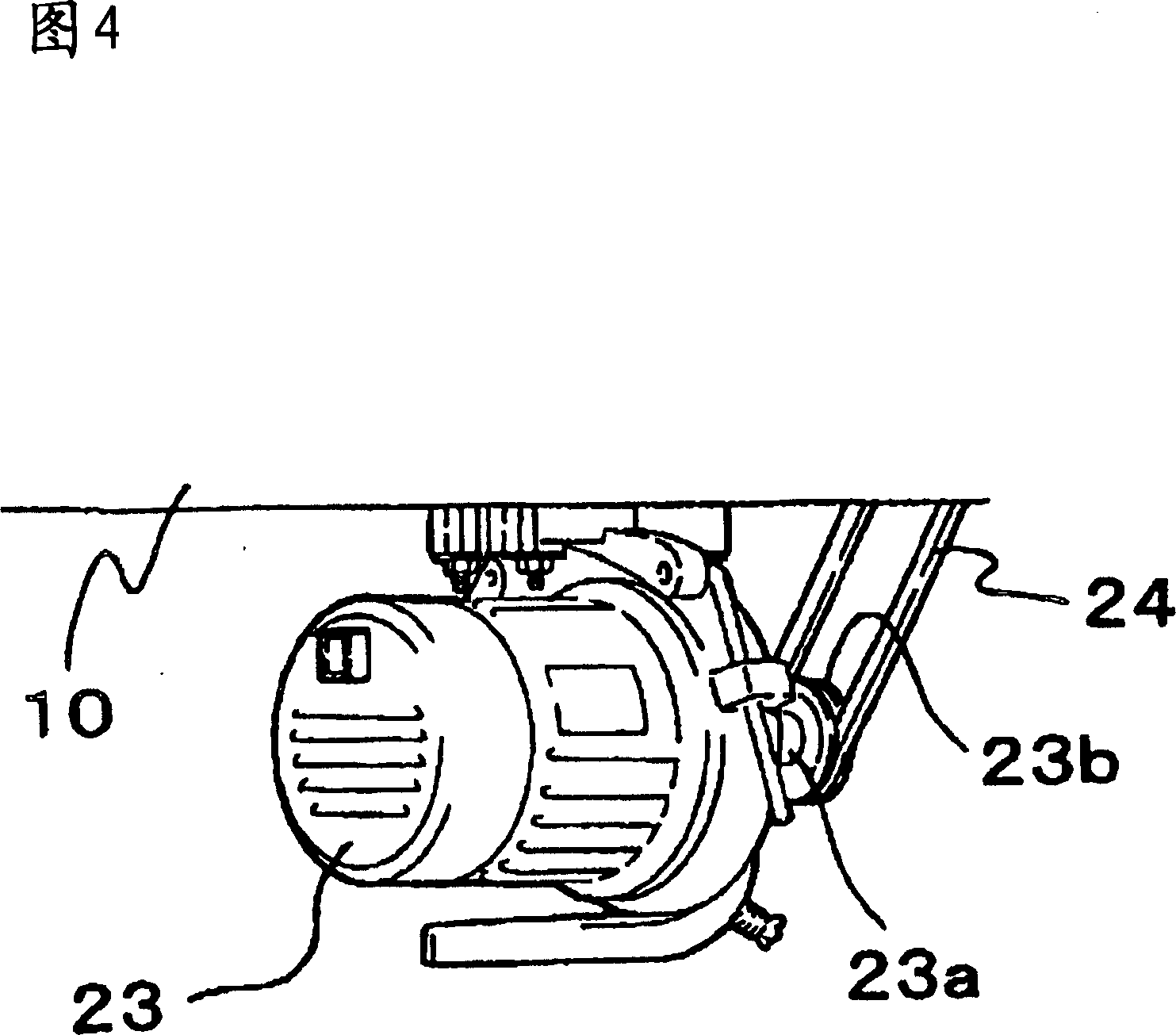

[0032] Embodiments of the present invention will be described below with reference to the drawings. The machine base 1 extends along the cloth feeding direction F, and the base end of the machine base 1 is connected with the horizontal arm 2 . As shown in FIG. 1 , the horizontal arm 2 extends obliquely relative to the machine base 1 , and has a head 3 at its front end. The head 3 has a needle drive mechanism and a presser foot mechanism, and the presser foot 4 of the presser foot mechanism is biased toward the needle plate 5 on the machine base 1 by a spring (not shown). A spindle 6 is pivotally supported on the horizontal arm 2 . The main shaft 6 is arranged along the length direction of the horizontal arm 2 , and one end of the main shaft 6 protrudes outward from the horizontal arm 2 . The horizontal arm 2 is fixed on the bracket 8 by screws 7 , and the bracket 8 is fixed on the workbench 10 by screws 9 .

[0033] A through hole 8a is formed through the bracket 8, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com