Double-blades double-cylinders drum of coal mining machine

A shearer and blade technology is applied in the field of double-blade and double-cylinder drums of shearers, which can solve the problems of inconvenient replacement of picks and poor static balance, and achieve the effects of improving work stability, material saving and loading efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

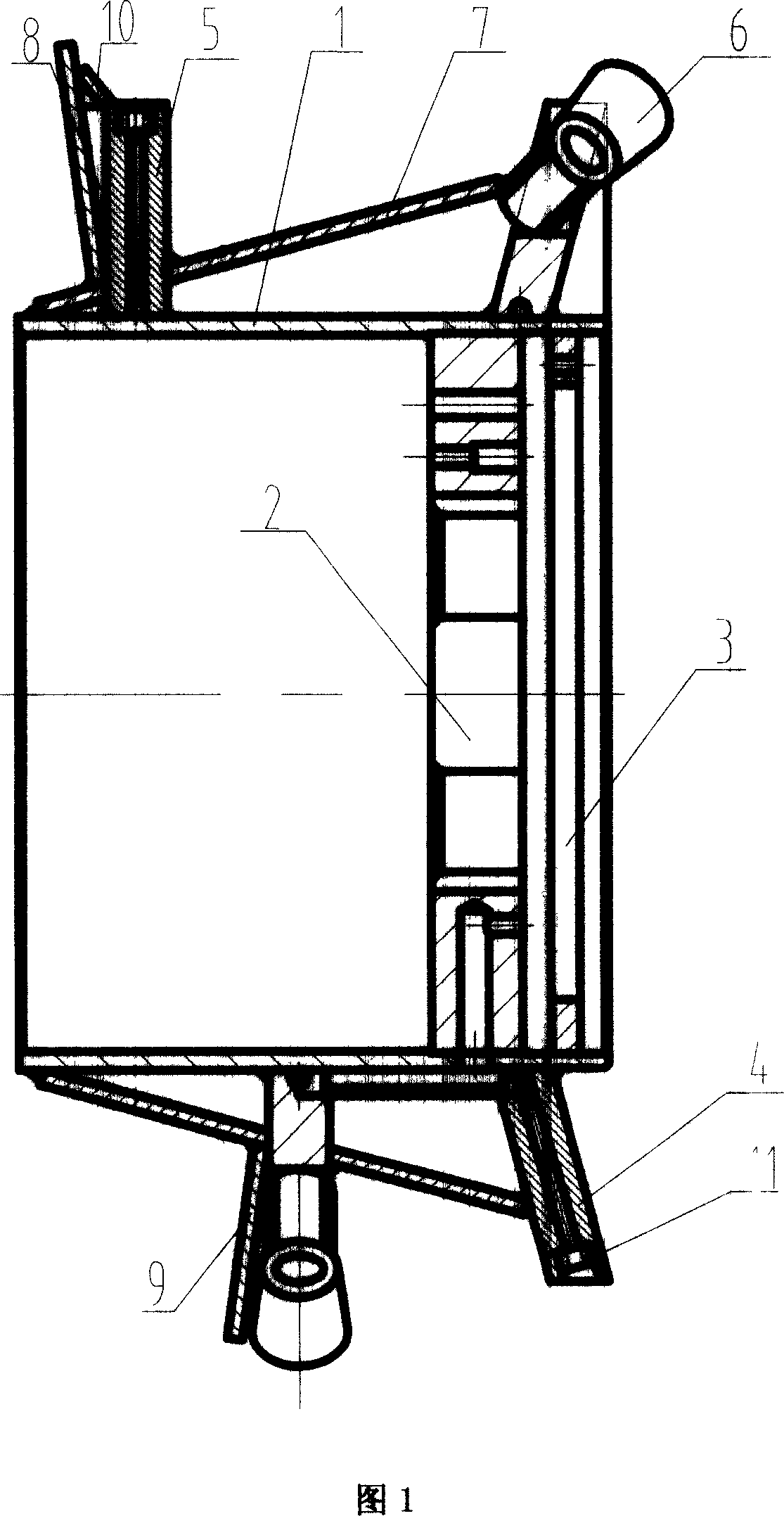

[0021] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: the present embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and processes are provided, but the protection scope of the present invention is not limited to the following implementations example.

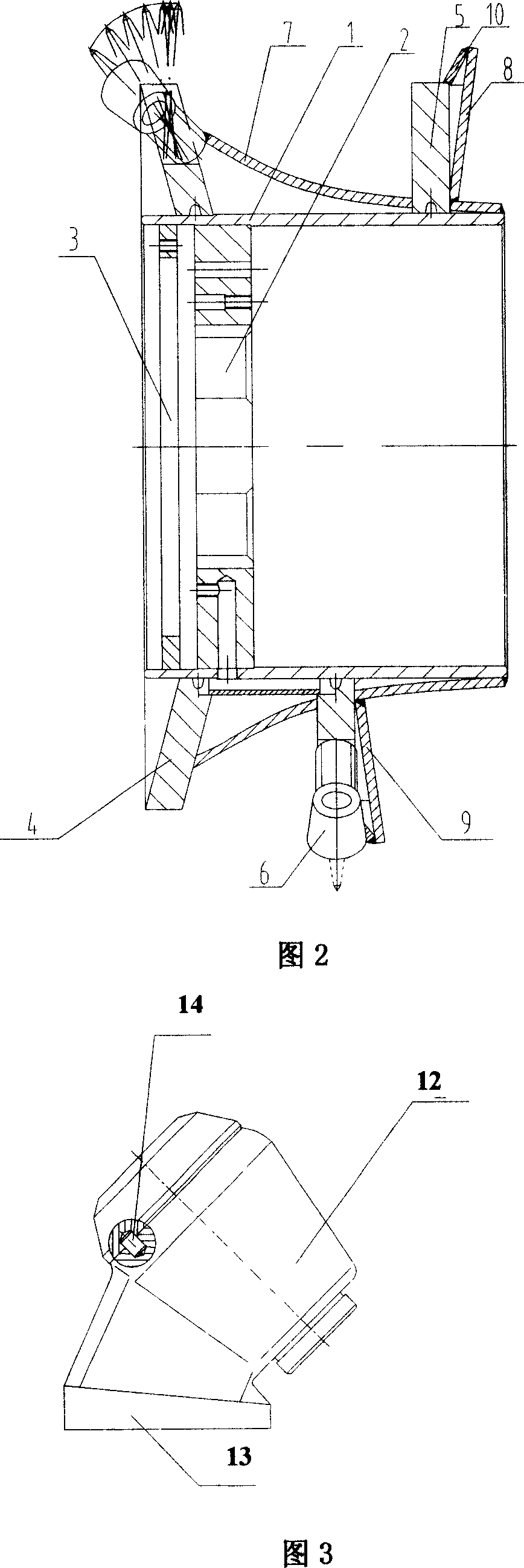

[0022] As shown in Figure 1-2, the double-blade double-cylinder drum of the shearer described in this embodiment includes: an inner cylinder 1, a connecting plate 2, an end plate 3, an end plate 4, a cutting blade 5, and a gear seat 6. Outer shell 7, rib plate 8, loading vane 9, sealing plate 10, nozzle seat 11. The connection relationship is as follows: the connection plate 2, the end plate 3 are welded together with the inner cylinder 1, the cutting blades 5 are welded on the inner cylinder 1, and the loading blades 9 are welded on the outer cylinder 7. The gear seat 6 and the n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com