Axle gear box shifting locking mechanism

A technology for axle gearboxes and locking mechanisms, applied in belts/chains/gears, mechanical equipment, components with teeth, etc., can solve problems such as unreasonable structures, damage to thin-walled meshing sleeves or gears, and complex forces. Achieve the effect of reducing the possibility of misoperation, improving reliability, and achieving the best reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

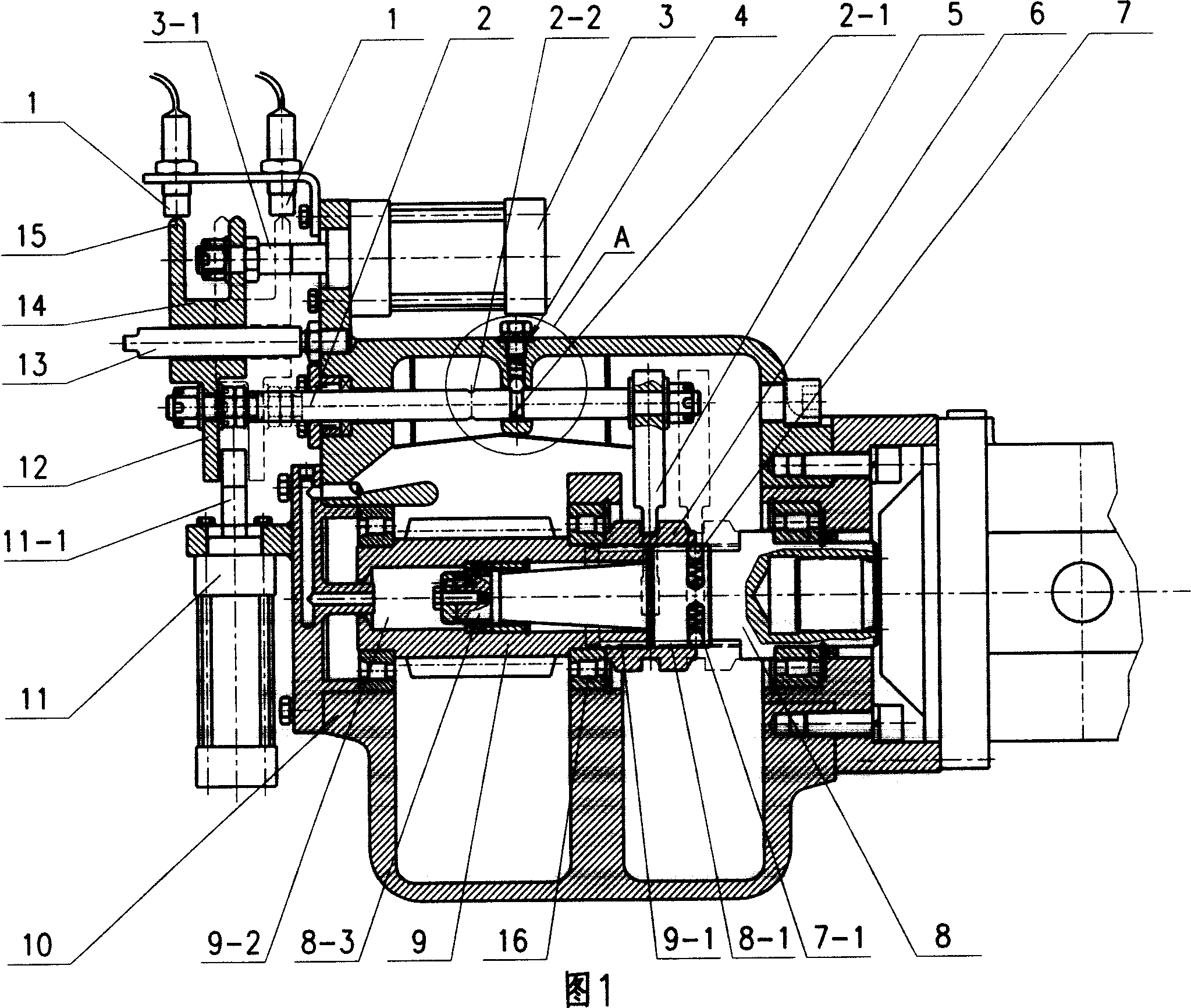

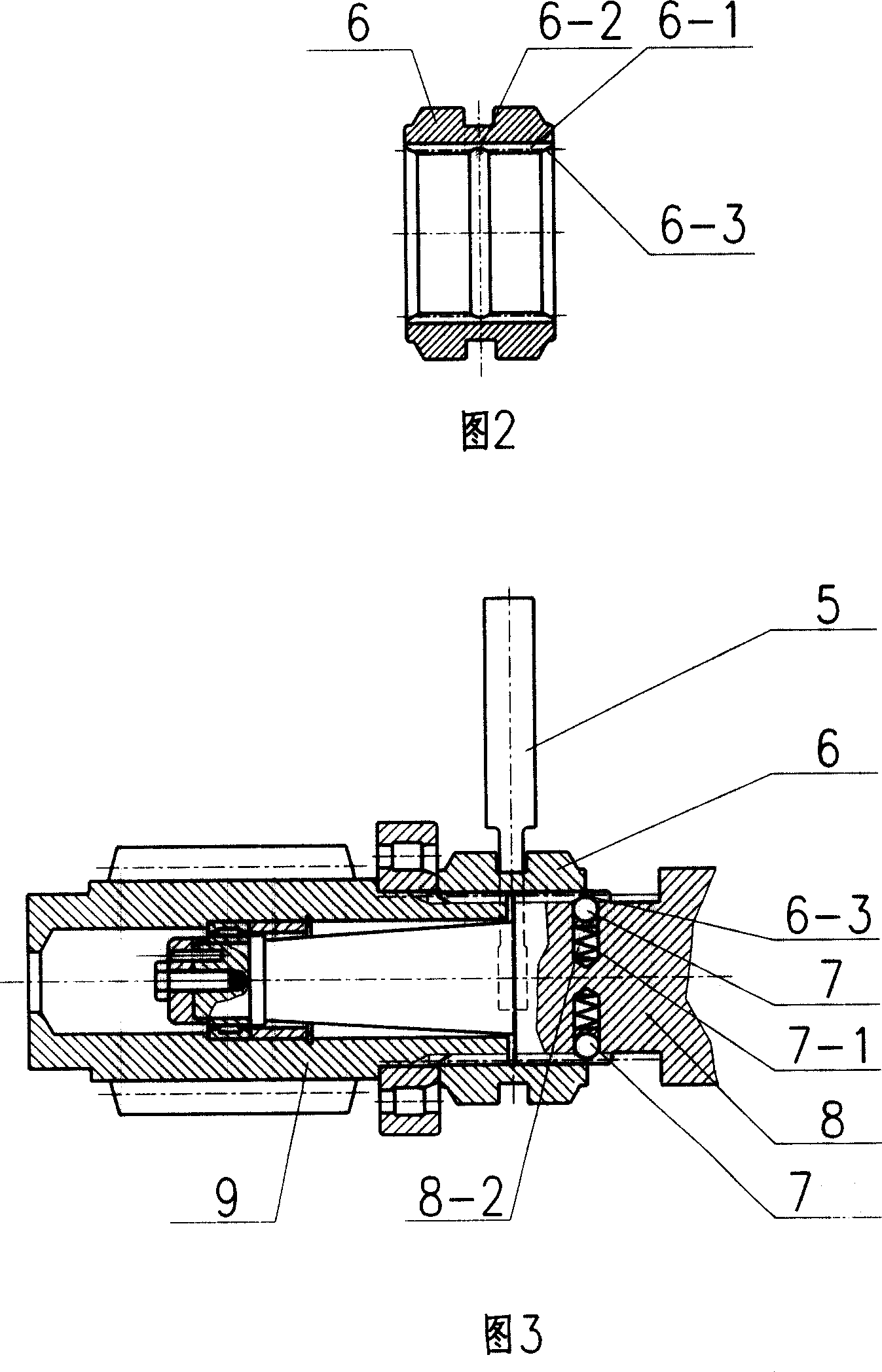

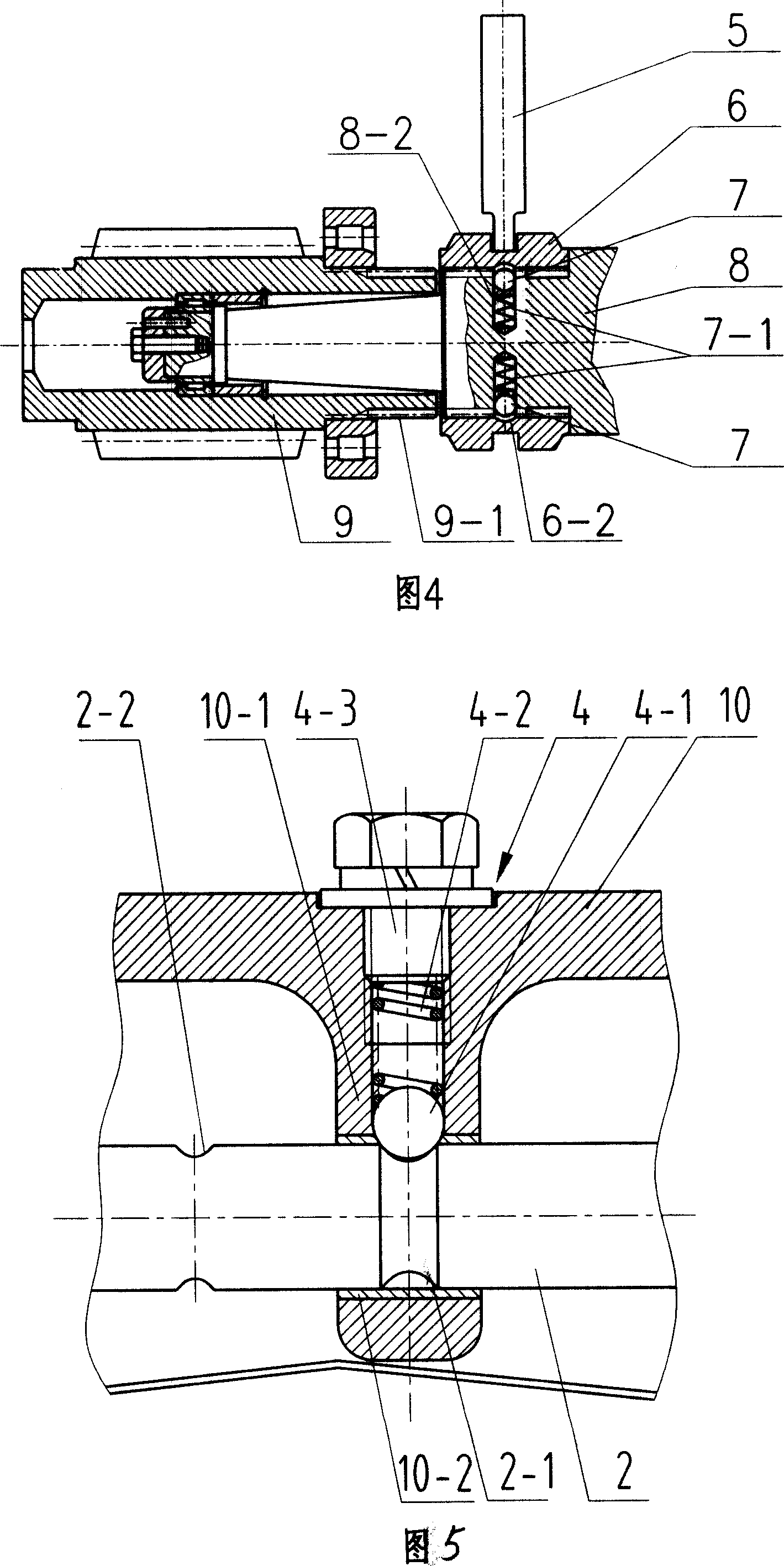

[0022] The present invention is described in further detail below in conjunction with the embodiment that accompanying drawing provides.

[0023] As shown in Figures 1, 2, 3, and 4, the axle gear box shift locking mechanism of the present invention includes a toggle mechanism mounted on the box body 10, an engaging sleeve 6 and an active drive with an external spline 9-1. The gear shaft 9 is connected to the engagement sleeve 6 by the transmission of the toggle mechanism, the engagement sleeve 6 has an internal spline 6-1, the inner hole wall of the engagement sleeve 6 has a neutral groove 6-2, and one end of the driving gear shaft 9 is connected in series with a The key shaft 8 has an external spline 8-1 on the spline shaft 8, and the external spline 8-1 corresponds to the external spline 9-1 of the driving gear shaft 9, and the spline shaft 8 is provided with a positioning member 7 and Its positioning spring 7-1, and the end of the engaging sleeve 6 is also provided with a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com