Swinging funnel used for paving bottom flavoring of sintering machine

A funnel and bottom material technology, which is applied in the field of swing funnels for sintering machine bottom materials, can solve the problems of sintering efficiency impact, high manufacturing cost, and uneven sintering quality, so as to reduce uneven sintering speed, improve sintering efficiency, and improve The effect of sintered quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

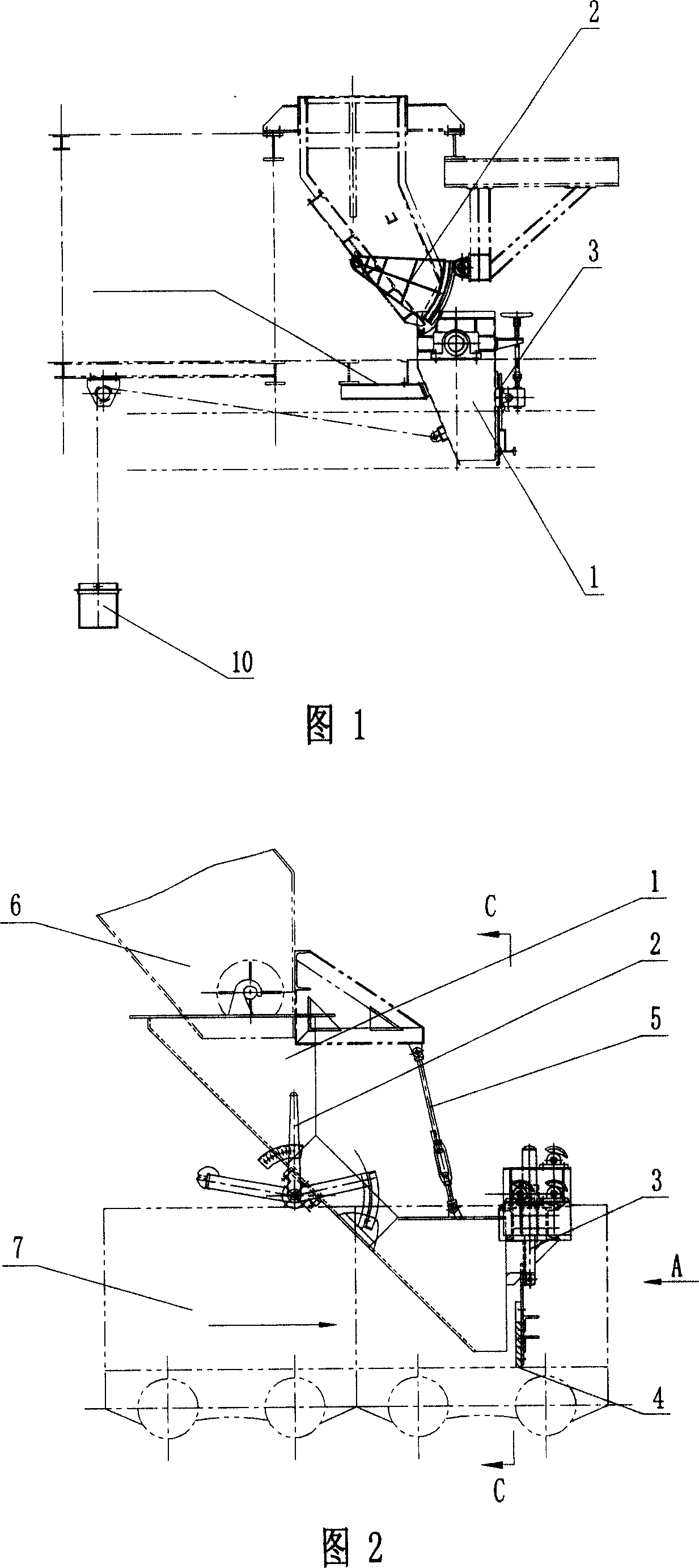

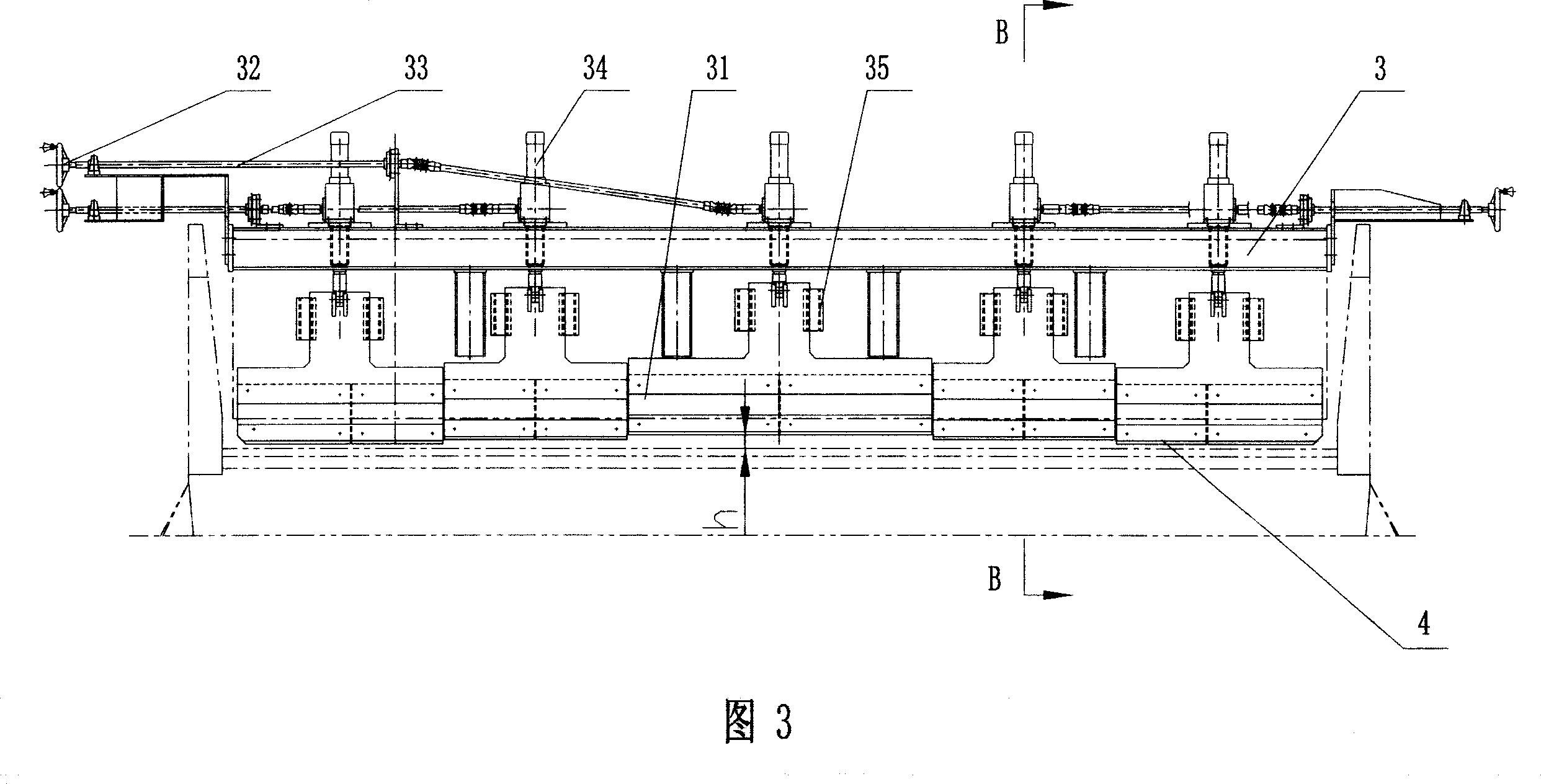

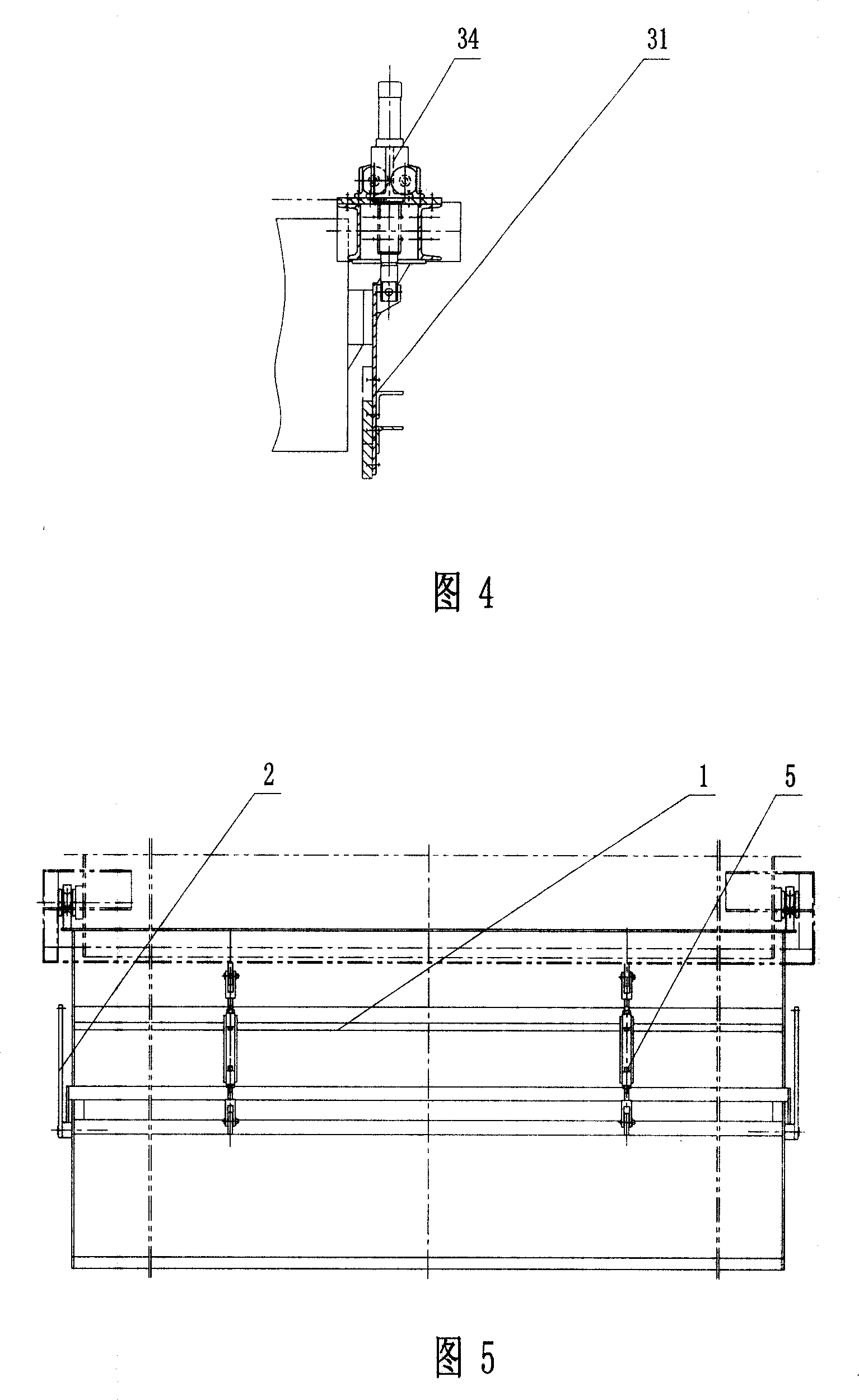

[0021] As shown in Fig. 2 to Fig. 5, a swing funnel for sintering machine bottom material includes a funnel body 1, a rotary gate 2 and an adjusting gate device 3, the rotating gate 2 is installed in the middle of the funnel body 1, and the adjusting gate device 3 is installed It is arranged in front of the funnel body 1 and adjusts the height h of the gate 4 of the gate device 3 to decrease gradually from the middle to both sides. The sintering machine base material is laid on the grate plate of the trolley to achieve unequal thickness. The thickness of the base material layer 8 decreases from the middle to both sides, which can greatly reduce the adverse effects of the edge effect, so that the sintering material layer can be spread over the entire width of the trolley. The air permeability in the direction is basically the same, effectively reducing the phenomenon of uneven sintering speed, improving sintering quality and sintering efficiency. In the present embodiment, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com