Fermentation process of Pu'er raw materials

A fermentation process, Pu-erh raw meal technology, applied in the field of Pu-erh raw meal fermentation process, can solve the problems of different fermentation degrees, different air permeability, and affect the taste of tea, and achieve the effect of uniform air permeability, strong air permeability, and pure and long-lasting tea flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042]A fermentation process of Pu'er bond, including the following steps:

[0043]Category: Picking the Pizza Pu'er bonze is separated by the bud tip and the bud leaves, then cleaning separately;

[0044]Silver: Pull the tip and bud leaves after cleaning, the thickness of the stall is 5mm, and the natural air dried until the water content of the bud tip is 72%, and the water content of the bud leaves is 65%;

[0045]青: The bud tip and the bud leaves are carried out separately, and the killing temperature of the bud tip is 230 ° C, the killing temperature of the bud leaves is 280 ° C, and the killing time is 8 minutes.

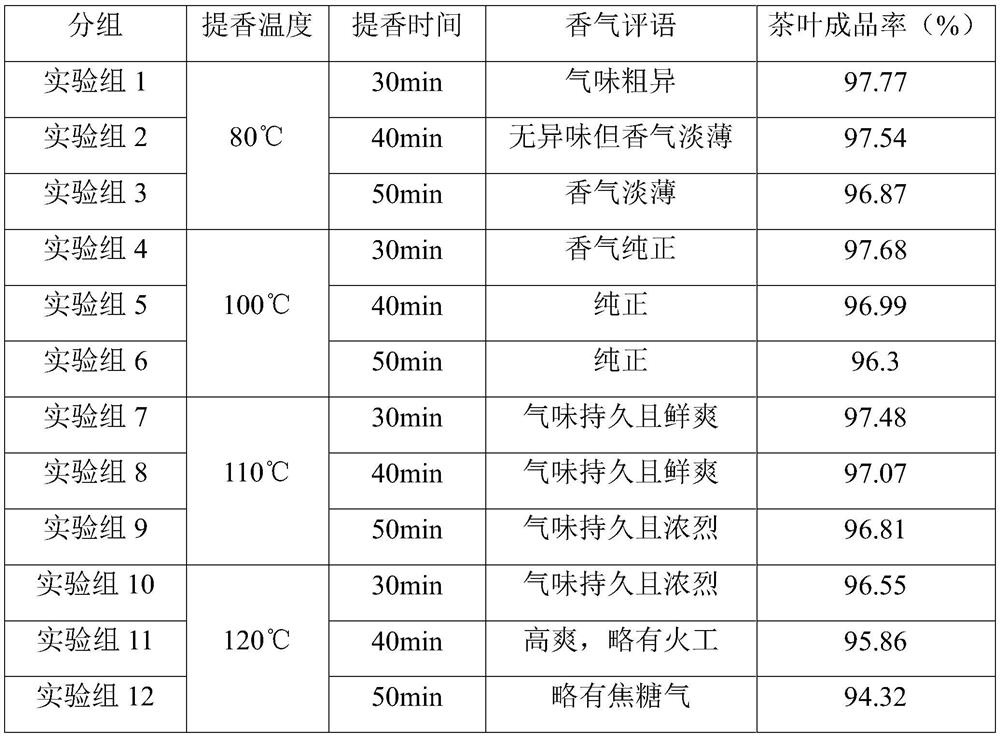

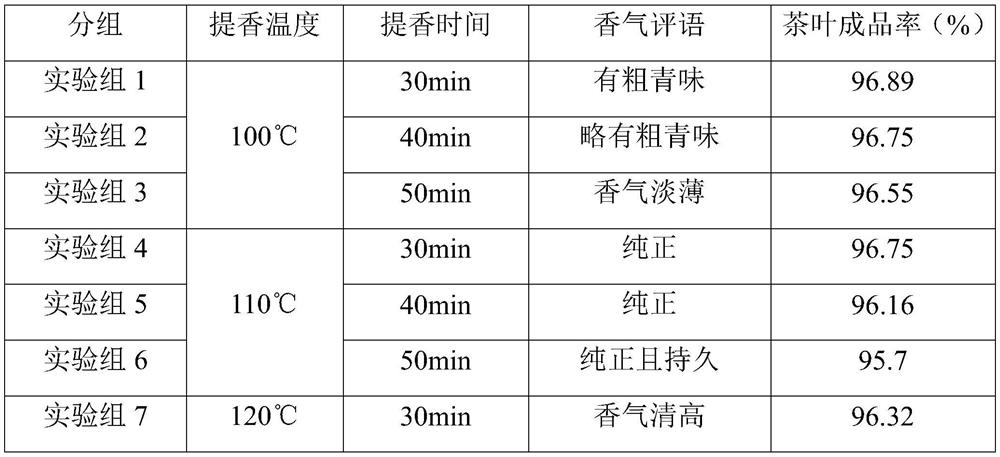

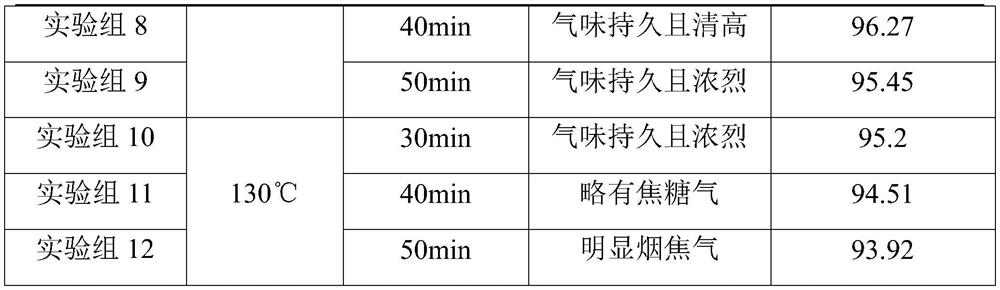

[0046]Jixiang: The flying bud tip and bud leaves will perform infrared tip of the bud tip of 100 ° C, with a fragrant time of 30 min, and the francium of the bud leaves is 110 ° C, and the fragrance time is 40 min.

[0047]揉 捻: Put the buds and bud leaves after the fragrance, the bud machine is cooled, the bud tip is 10 min, which is lightly pressing 5 minutes, then the heavy pres...

Embodiment 2

[0051]A fermentation process of Pu'er bond, including the following steps:

[0052]Category: Picking the Pizza Pu'er bonze is separated by the bud tip and the bud leaves, then cleaning separately;

[0053]Silver: Pull-off the tip and bud leaves after the cleaning, the thickness of the stall is 10mm, and the natural air dry is 75%, and the water content of the bud leaves is 70%;

[0054]青:: The bud tip and bud leaves are carried out by steam hot air, and the killing temperature of the bud tip is 250 ° C, killing 8 min, the killing temperature of the bud leaves is 270 ° C, and the killing time is 10 min.

[0055]Jixiang: The infrared fragrance treated by the murderous buds and buds, the jettothe temperature of the bud tip is 110 ° C, the frank is 30 min, and the francium of the bud leaves is 120 ° C, and the fragrance time is 30 min.

[0056]捻 捻: Put the buds and bud leaves after the fragrance to cool, the bud tip is 15 min, the first light pressure is 5 minutes, then the heavy pressure is 10 minute...

Embodiment 3

[0060]A fermentation process of Pu'er bond, including the following steps:

[0061]Category: Picking the Pizza Pu'er bonze is separated by the bud tip and the bud leaves, then cleaning separately;

[0062]Silver: Pull the tip and bud leaves after the cleaning, the thickness of the stall is 8mm, and the natural air dried until the water content of the bud tip is 72%, and the water content of the bud leaves is 68%;

[0063]Kill blue: The bud tip and bud leaves are carried out by steam hot air, and the killing temperature of the bud tip is 240 ° C, killing 10 min, and the killing temperature of the bud leaves is 280 ° C, and the killing time is 8 minutes.

[0064]Jixiang: Carbon-suction in the buds and bud leaves will be carbon-suction, the jettot temperature of the bud tip is 100 ° C, the fragrant time is 30 min, the francium of the bud leaves is 110 ° C, the fragrance time is 50min .

[0065]捻 捻: Put the buds and bud leaves after the fragrance, the budding machine is cold, the bud tip is 12min, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com