Loading system and method for loading substrates with electrical components

A technology for assembling systems and components, applied in the direction of electrical components, electrical components, etc., can solve the problems of increasing investment in structure, economy and control technology, increasing the idle length of guide beams, increasing swings, etc. Assembly process, effect of stabilizing the support structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

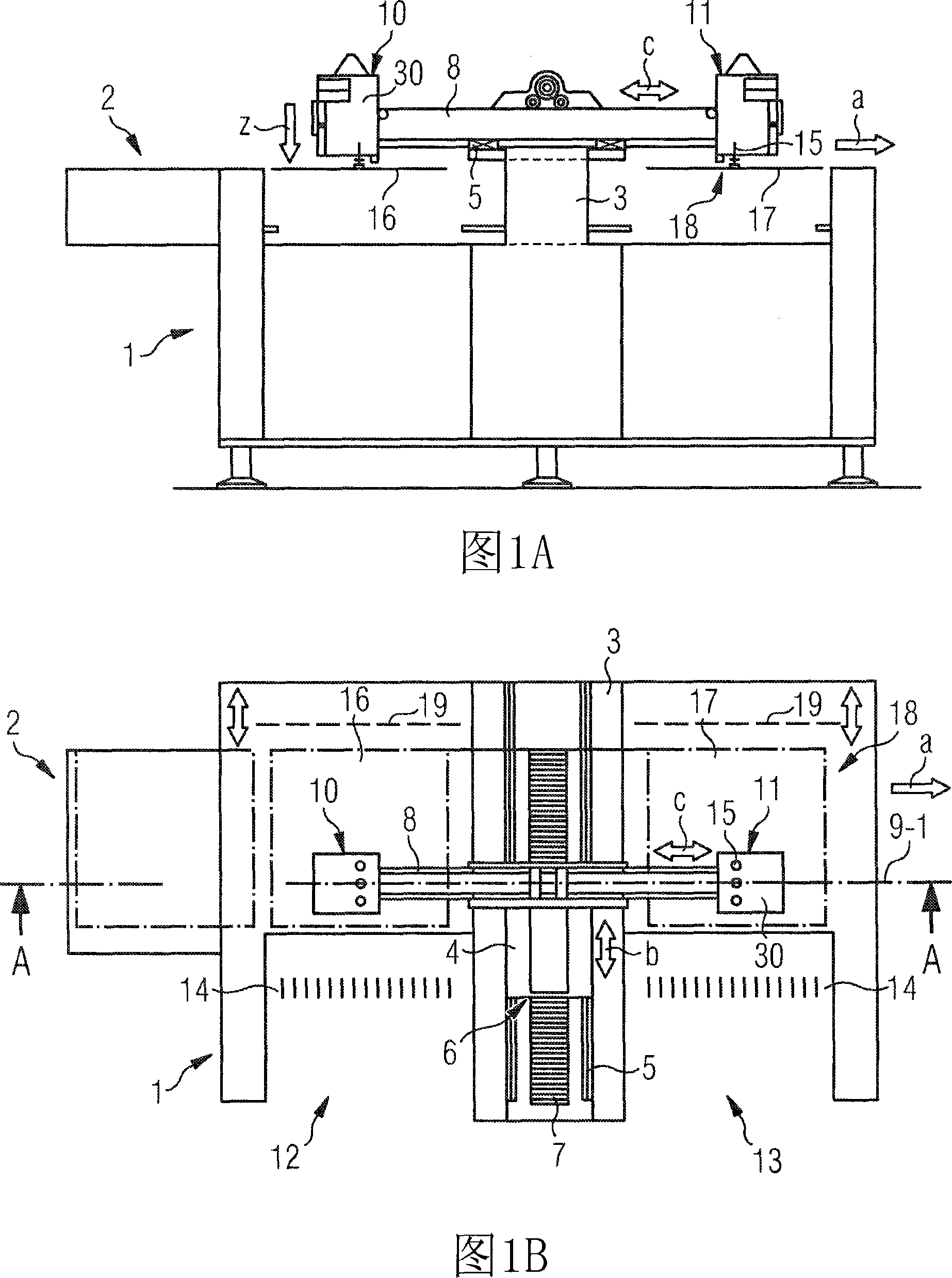

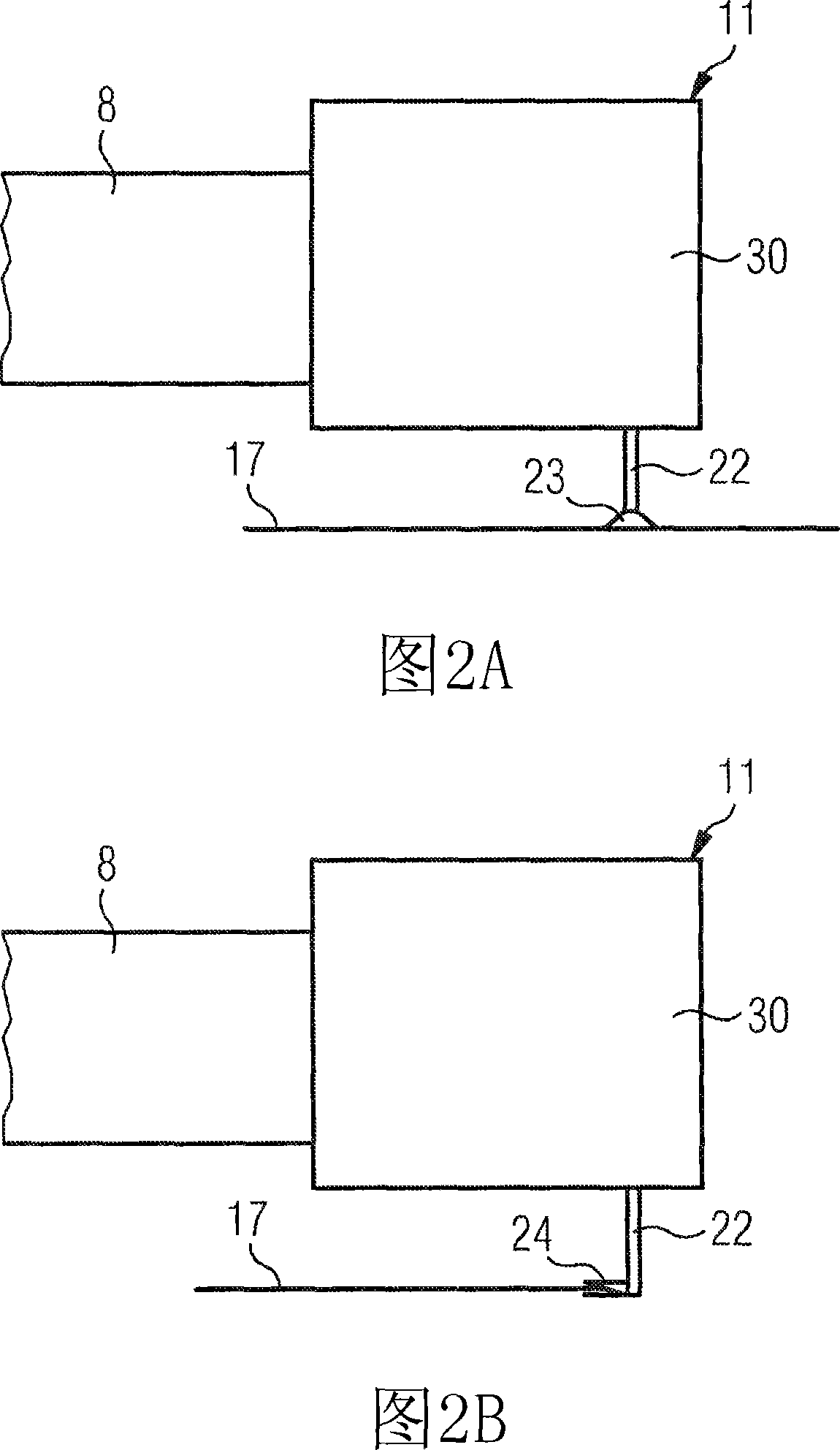

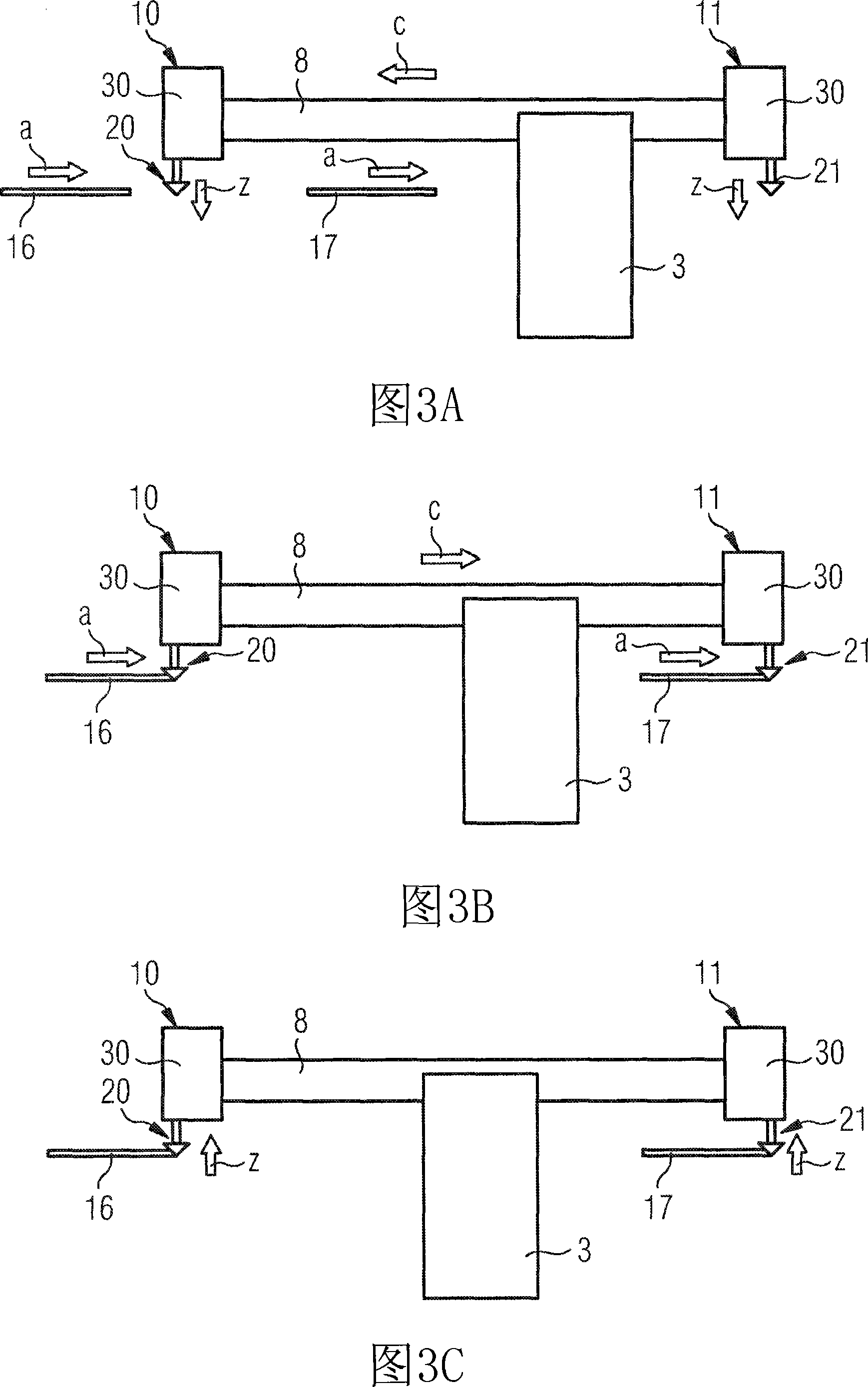

[0036] Figures 1a and 1b are schematic representations of an embodiment of the assembly system of the present invention. The assembly system has a base frame 1 on which a transport line 2 for transporting substrates in a transport direction (arrow a) is arranged. Wherein, the conveying line can be, for example, a simple conveying belt with a driving mechanism. A main support 3 of the assembly system is arranged in such a way that it spans the conveying line 2 like a bridge in a direction perpendicular to the conveying direction. Arranged on the main carrier 3 is a first bearing carriage 4 which is displaceable in a movement direction (arrow b) perpendicular to the conveying direction. Wherein, the first support slide 4 moves along the main support 3 under the guidance of the corresponding linear guide device 5 and is driven, for example, by a first linear motor 6 . Arranged on the main carrier 3 are permanent magnets 7 serving as the stationary part of the first linear motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com