Production process of popsicle with shell containing large grains

A technology of large particles and production technology, which is applied in food science, frozen desserts, applications, etc., can solve problems such as the inability to produce ice cream, and achieve the effect of improving product quality and increasing color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

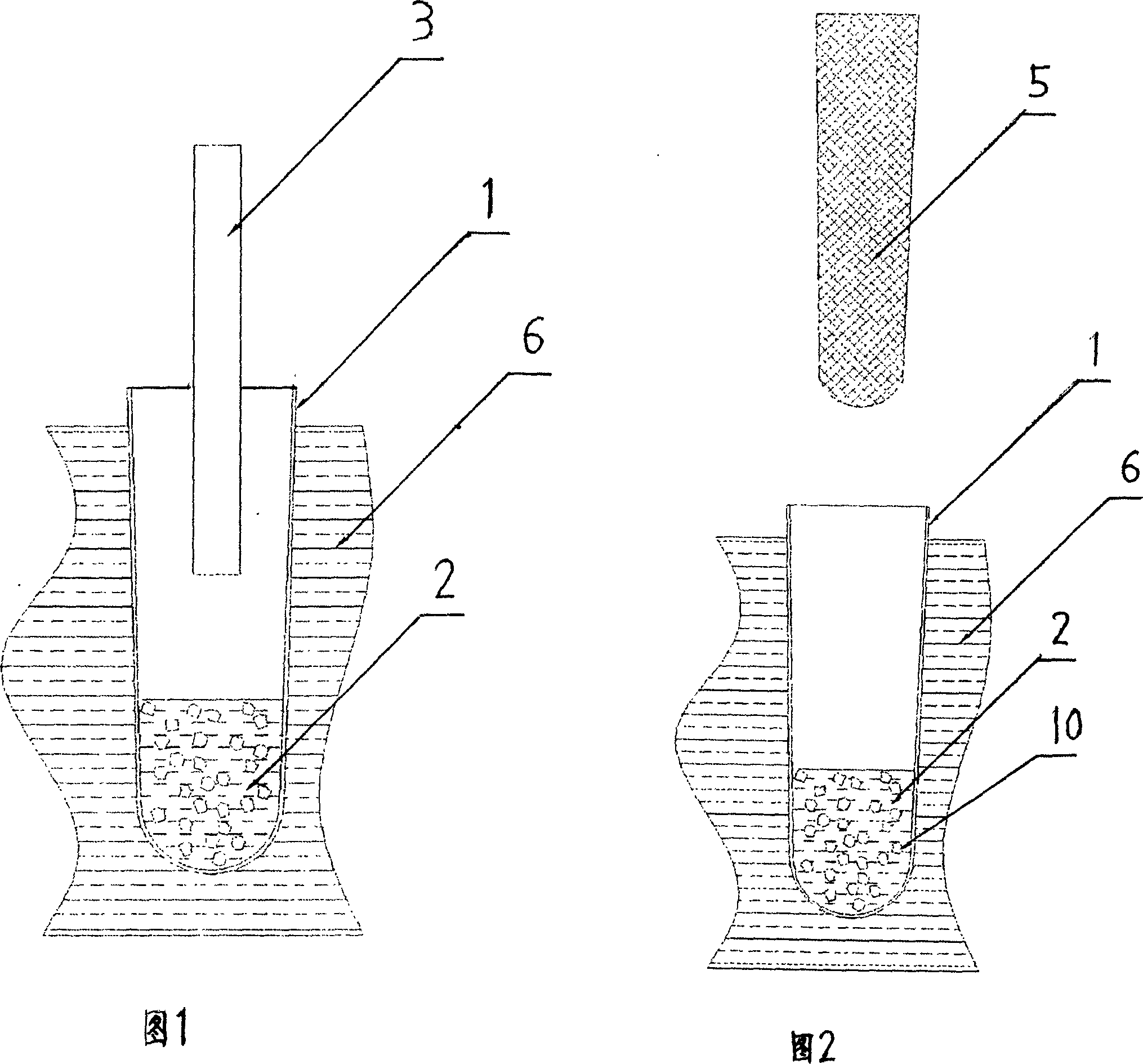

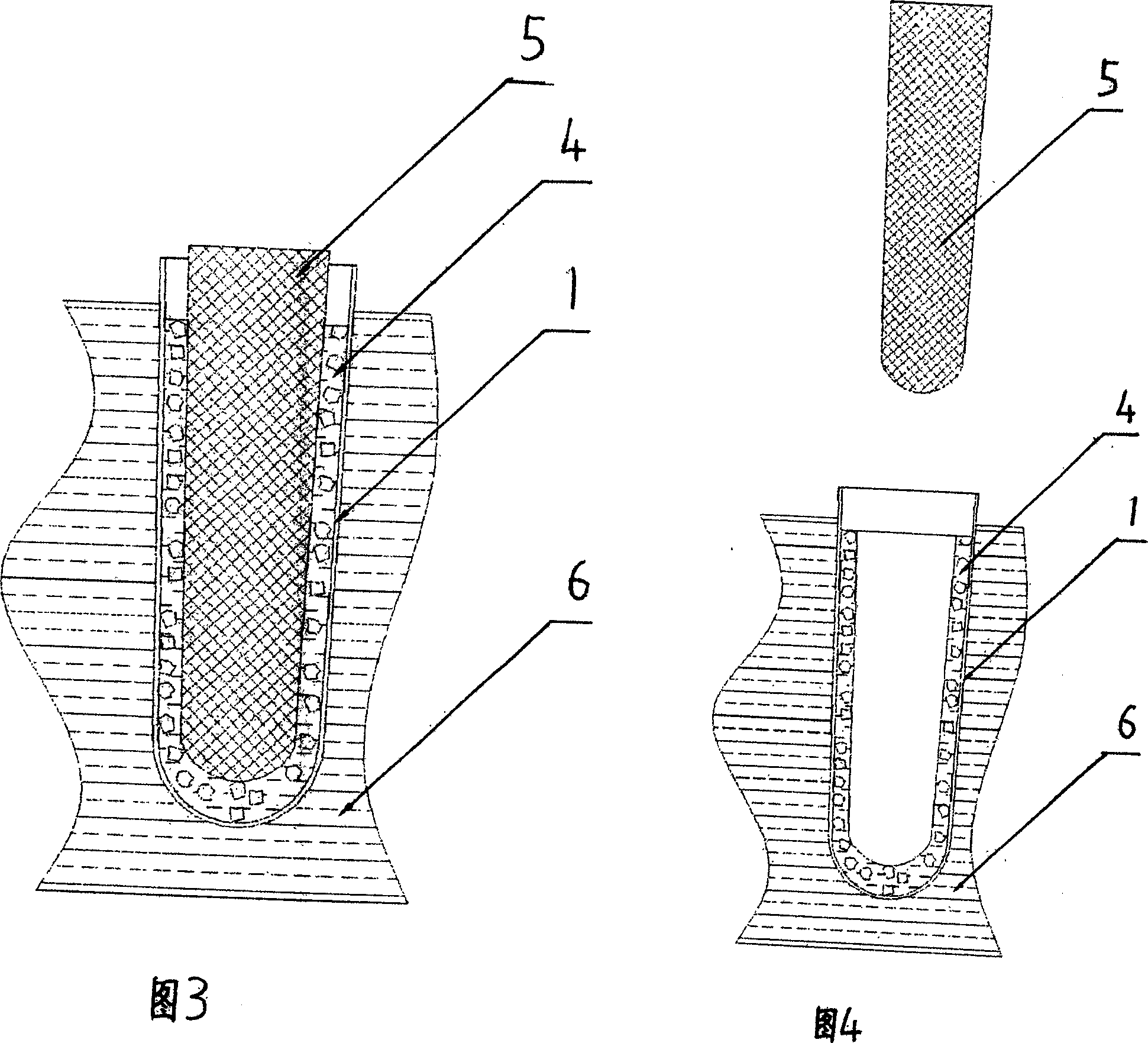

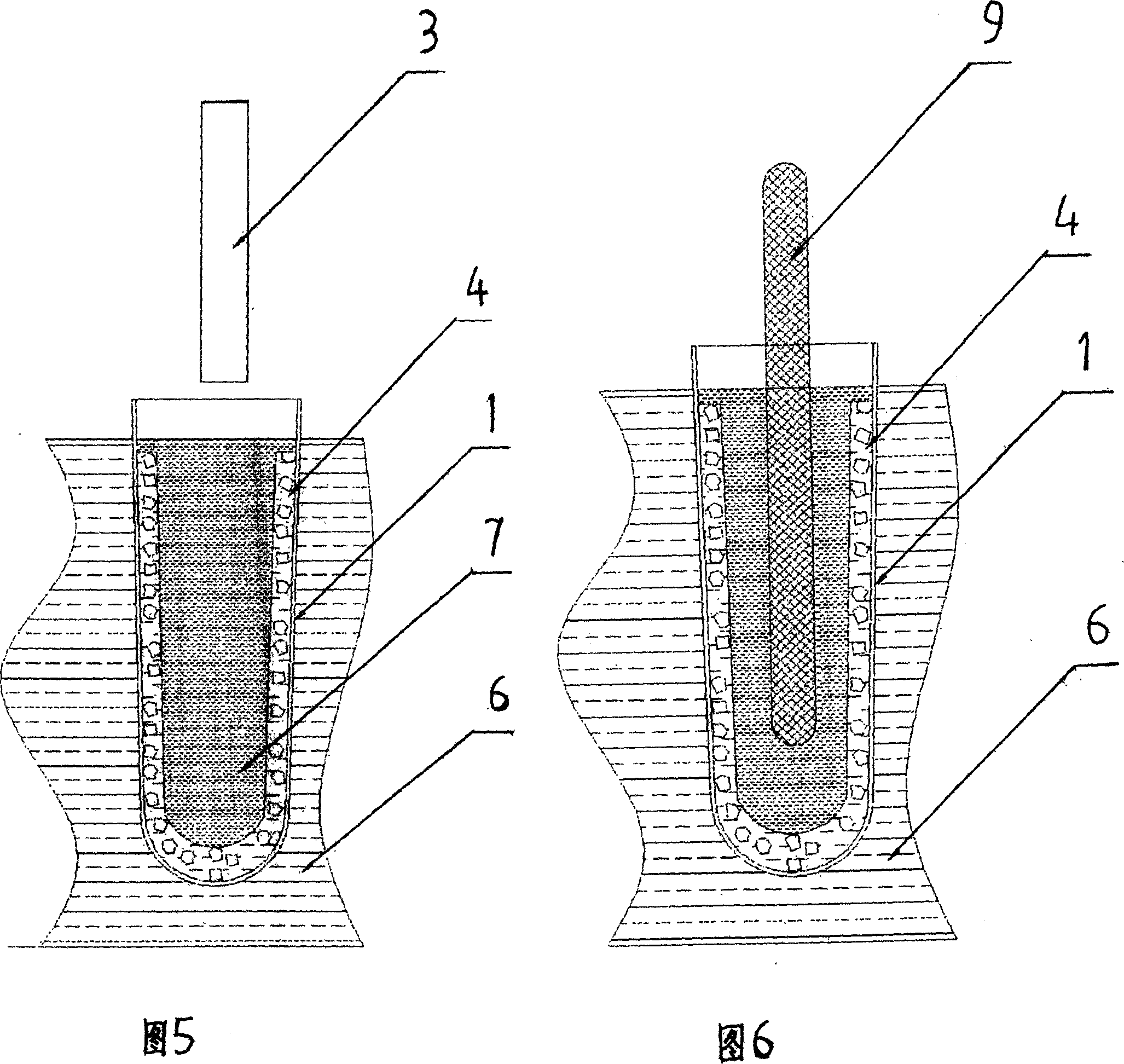

[0030] A kind of production technology of the ice cream that the inside of the ice cream shell contains the large particle nut shell that diameter is 2mm, comprises the following steps:

[0031] 1. Inject the ice cream material liquid 2 (see Fig. 1) that contains the large grain nuts 10 with a diameter of 2 mm into the mold 1;

[0032] 2. Use the special-purpose presser 5 to squeeze the ice cream feed liquid 2 containing the large grain nuts 10 to a concentration of 28 ° Be, and the temperature is the mold 1 inner wall of the low-temperature salt water 6 of -28 ° C (see Figure 2); make the feed liquid It is close to the inner wall of the mold; the special molder refers to the solid structure whose shape matches the inner wall of the mold. There is a threaded hole on the upper part of the special molder, which is used to screw the screw into the threaded hole, which is convenient for fixing the handle. Hold the handle when operating , so that the special molder moves up and dow...

Embodiment 2

[0039] A kind of production technology of the ice cream that the inside of ice cream shell contains the large-grain fruit grain and the large-grain nut shell that diameter is 20mm, comprises the following steps:

[0040] 1. Inject the ice cream material liquid 2 (see Fig. 1) that contains diameter 20mm large-grained fruit grains and large-grained nuts 10 in mold 1;

[0041] ②Extrude the ice cream material liquid 2 containing large fruit particles and large nuts 10 to the inner wall of the mold 1 with a concentration of 32° Be and a temperature of -32° C. of low-temperature salt water 6 using a special molder 5 (see Figure 2) ; Make the material liquid close to the inner wall of the mold; the special molder refers to the solid structure whose shape matches the inner wall of the mold. There is a threaded hole on the upper part of the special molder, which is used to screw the screw into the threaded hole, which is convenient for fixing the handle and operating Hold the handle at...

Embodiment 3

[0047] A kind of production technology of the ice cream that the inside of ice cream shell contains the large particle jelly shell that diameter is 11mm, comprises the steps:

[0048] 1. Inject the ice cream material liquid 2 (see Fig. 1) that contains the large particle jelly 10 with a diameter of 11 mm into the mold 1;

[0049]2. Extrude the ice cream feed liquid 2 containing the large-particle jelly 10 to a concentration of 30 ° Be' and a temperature of the mold 1 inner wall of the low-temperature salt water 6 at -30° C. using the special press 5 (see Fig. 2); make the feed liquid It is close to the inner wall of the mold; the special molder refers to the solid structure whose shape matches the inner wall of the mold. There is a threaded hole on the upper part of the special molder, which is used to screw the screw into the threaded hole, which is convenient for fixing the handle. Hold the handle when operating , so that the special molder moves up and down in the mold, squ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com