Nanometer Pd material and its prepn process

A technology of palladium nanometer and cuboid, which is applied in the field of nanomaterials and achieves the effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

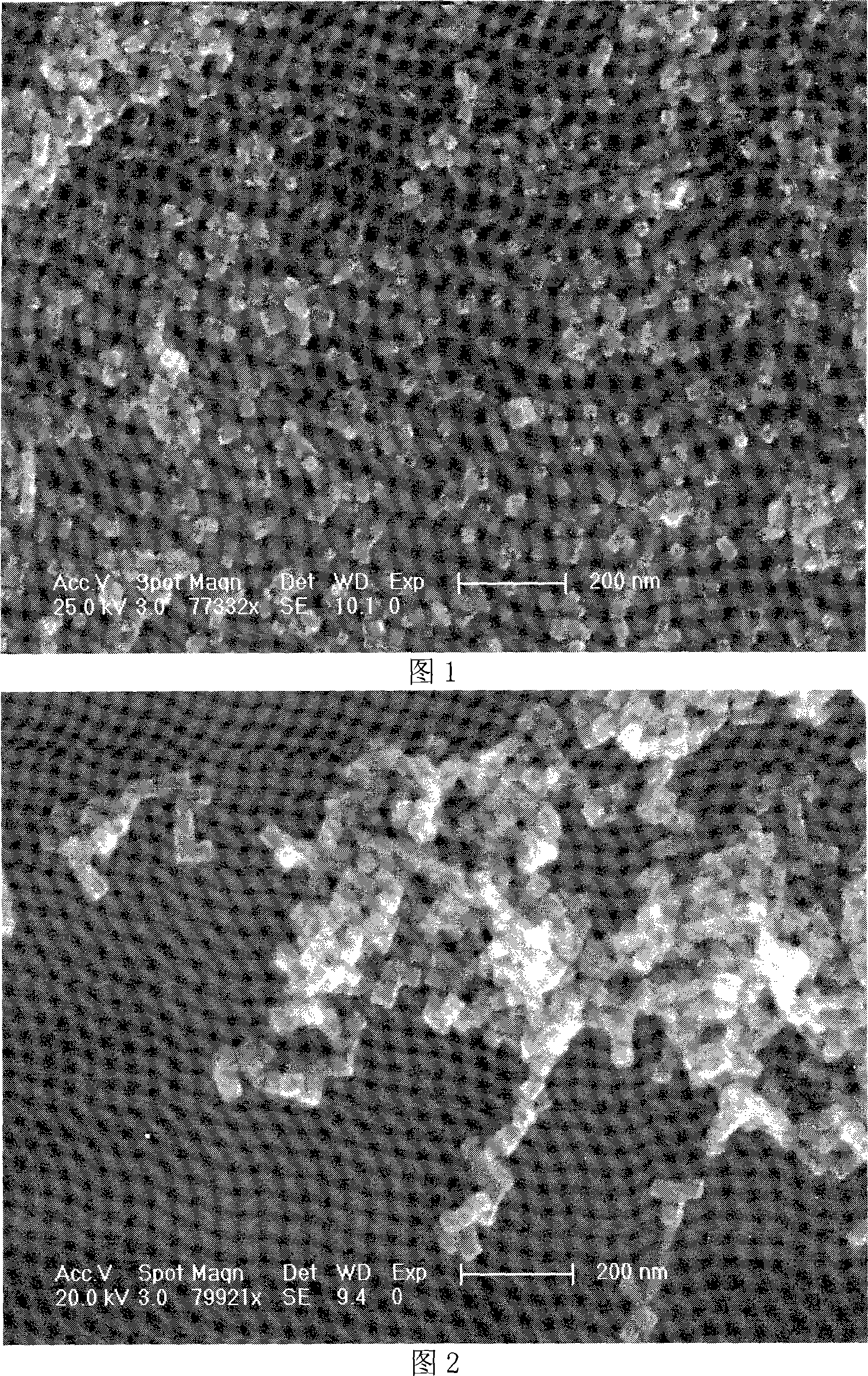

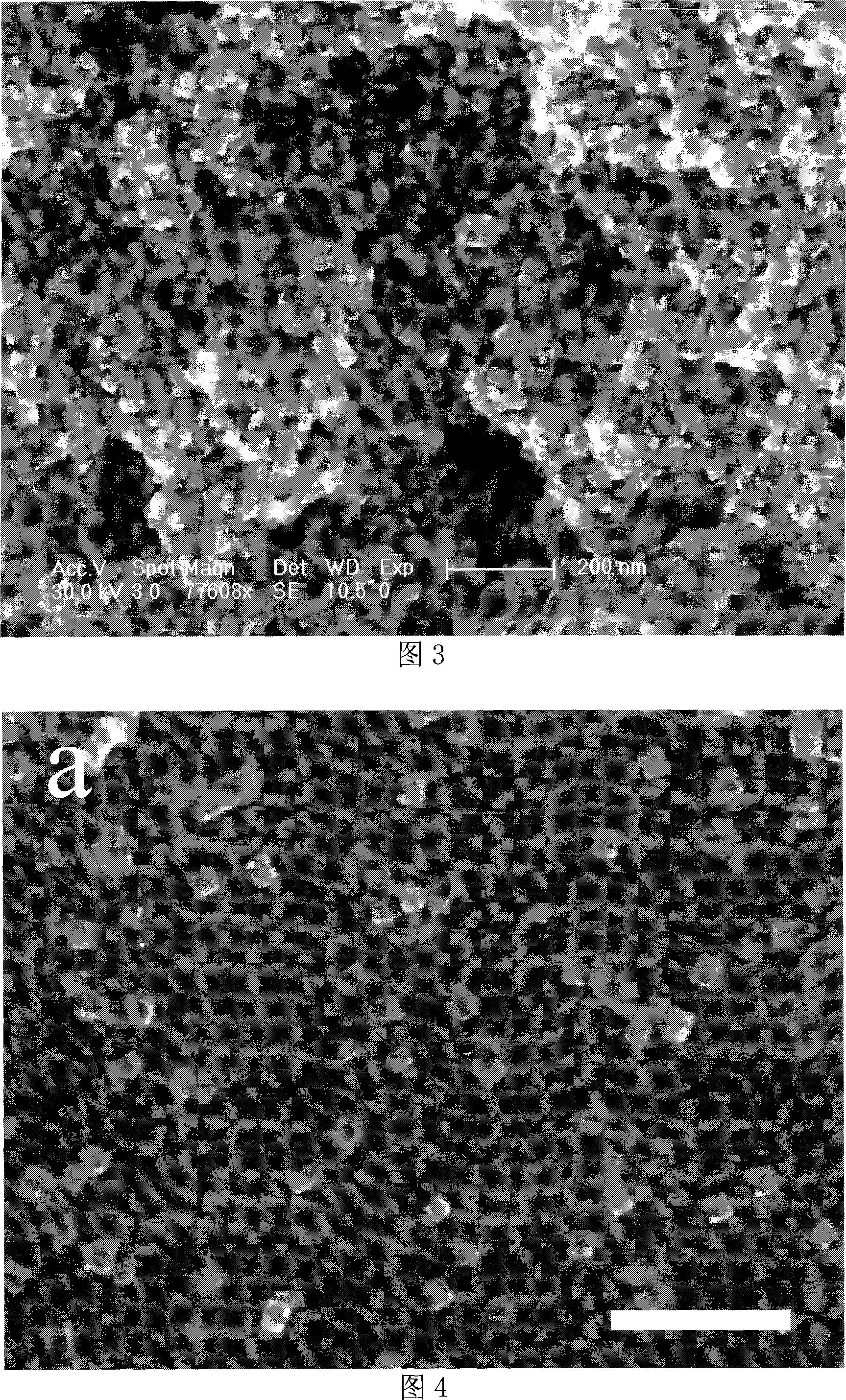

Embodiment 1

[0014] Mix 1 volume of 10 mM chloropalladic acid aqueous solution and 20 volumes of 12.5 mM hexadecyltrimethylammonium bromide aqueous solution, heat to 95 ° C, and then add 100 mM Ascorbic acid aqueous solution, after reacting for 30 minutes, the solution is centrifuged, and the collected precipitate is washed with water and dried to obtain palladium nano cuboid material.

Embodiment 2

[0016] Mix 1 volume of 10 mM chloropalladic acid aqueous solution and 20 volumes of 15 mM cetyltrimethylammonium bromide aqueous solution, heat to 65 °C, and then add 100 mM ascorbic acid with a volume ratio of 0.16:1 to 10 mM chloropalladic acid aqueous solution aqueous solution, after reacting for 30 minutes, the solution was centrifuged, and the collected precipitate was washed with water and dried to obtain palladium nano cuboids.

Embodiment 3

[0018] Mix 1 volume of 10 mM chloropalladic acid aqueous solution and 20 volumes of 25 mM hexadecyltrimethylammonium bromide aqueous solution, heat to 95 ° C, and then add 100 mMM ascorbic acid with a volume ratio of 0.16:1 to 10 mM chloropalladic acid aqueous solution aqueous solution, after reacting for 30 minutes, the solution was centrifuged, and the collected precipitate was washed with water and dried to obtain palladium nano cuboid material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com