Gear rack machining lathe

A technology for special lathes and racks, which is applied in metal processing, metal processing equipment, metal processing machinery parts, etc. It can solve the problems of different spacing and affect the use of racks, and achieve the effect of improving processing accuracy and reducing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

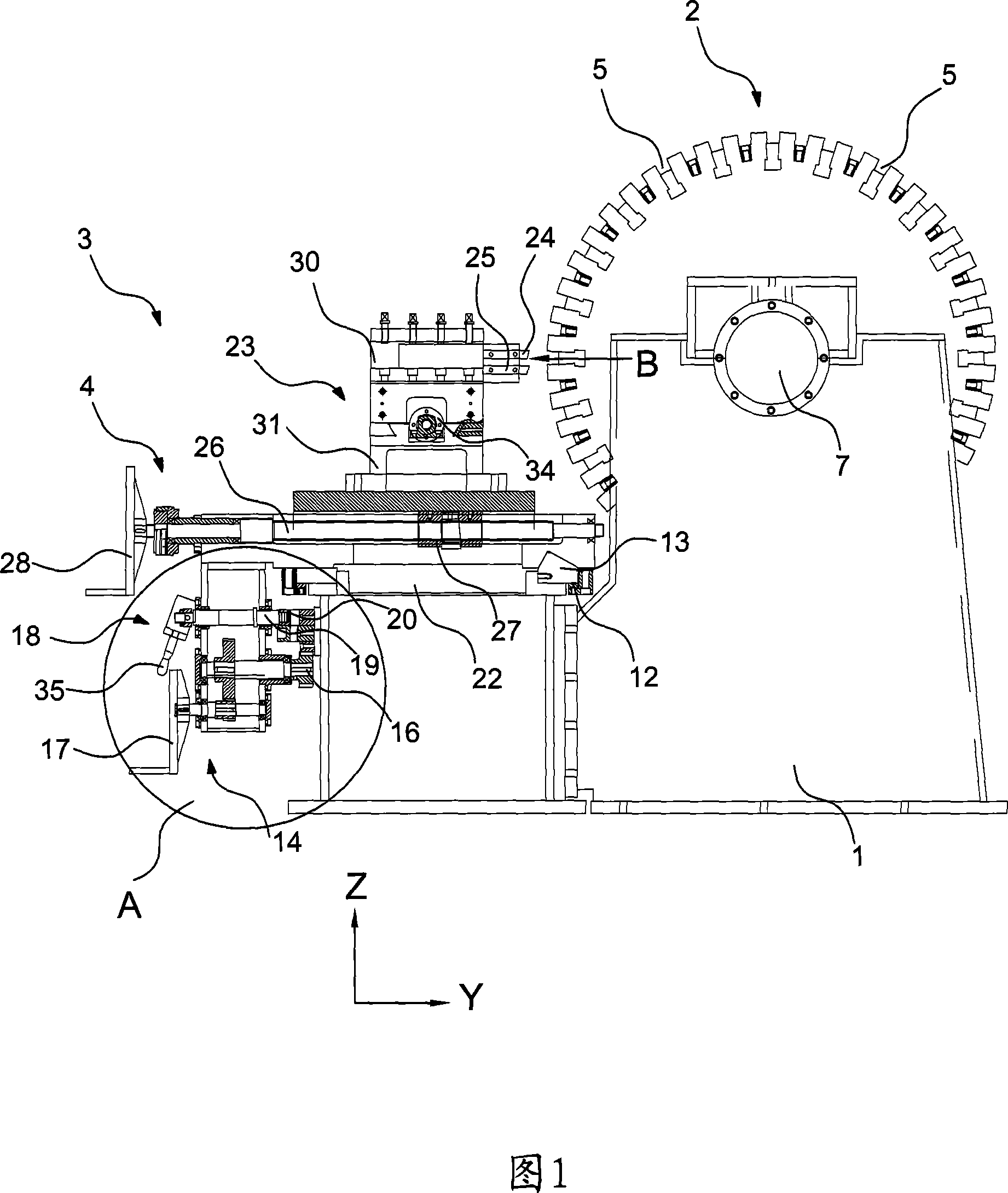

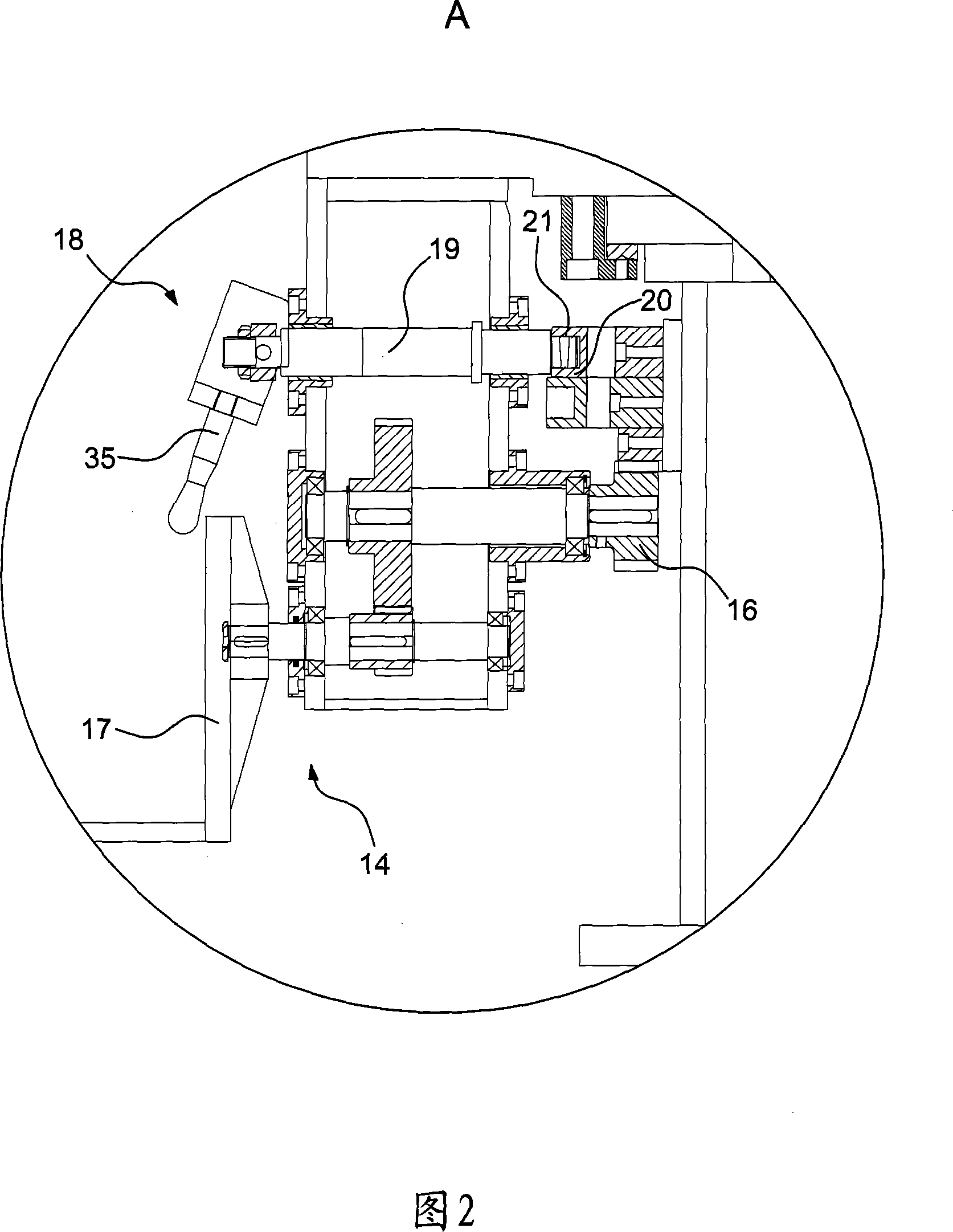

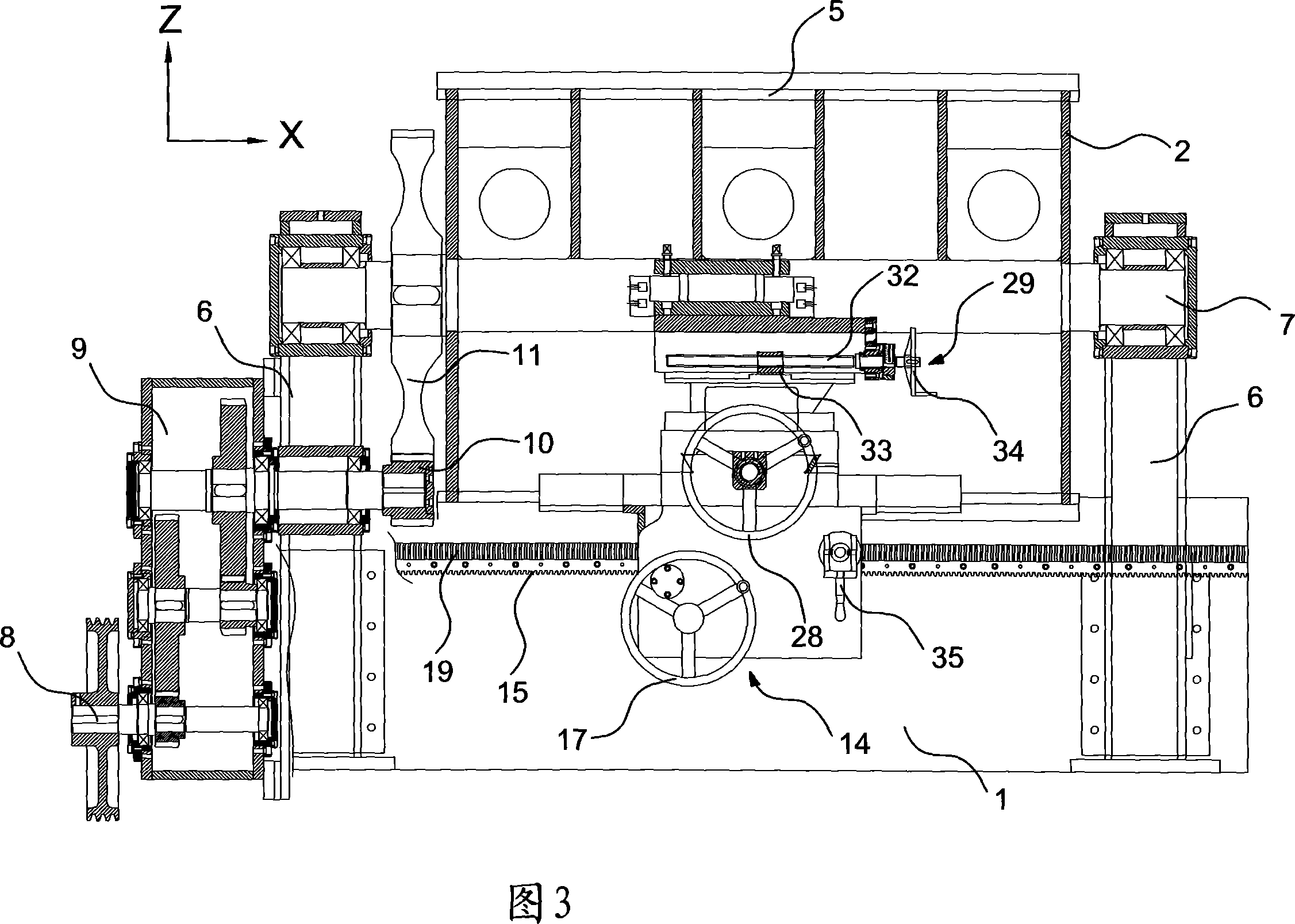

[0017] As shown in Figures 1 to 5, a special lathe for rack processing includes a machine tool seat 1, a worktable 2 arranged on the machine tool seat 1, and slidably arranged on the machine tool seat 1 along the X-axis direction and close to the worktable 2 of the rack machining head 3.

[0018] The worktable 2 is cylindrical, and is rotatably arranged on the machine tool base 1 around its own axis. The axis of the cylindrical worktable 2 extends along the X-axis direction. The outer circumferential wall of the worktable 2 is provided with a A plurality of installation grooves 5 for installing the rack and extending along the X-axis direction, the plurality of installation grooves 5 are distributed along the circumferential direction of the table 2, and the distance between two adjacent installation grooves 5 is smaller than the rack to be processed In this way, by installing multiple pre-machined racks in different installation slots 5, multiple racks can be machined at one ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap