Multifunctional heating furnace

A heating furnace, multi-functional technology, applied in the field of heating furnace, can solve the problem of high equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

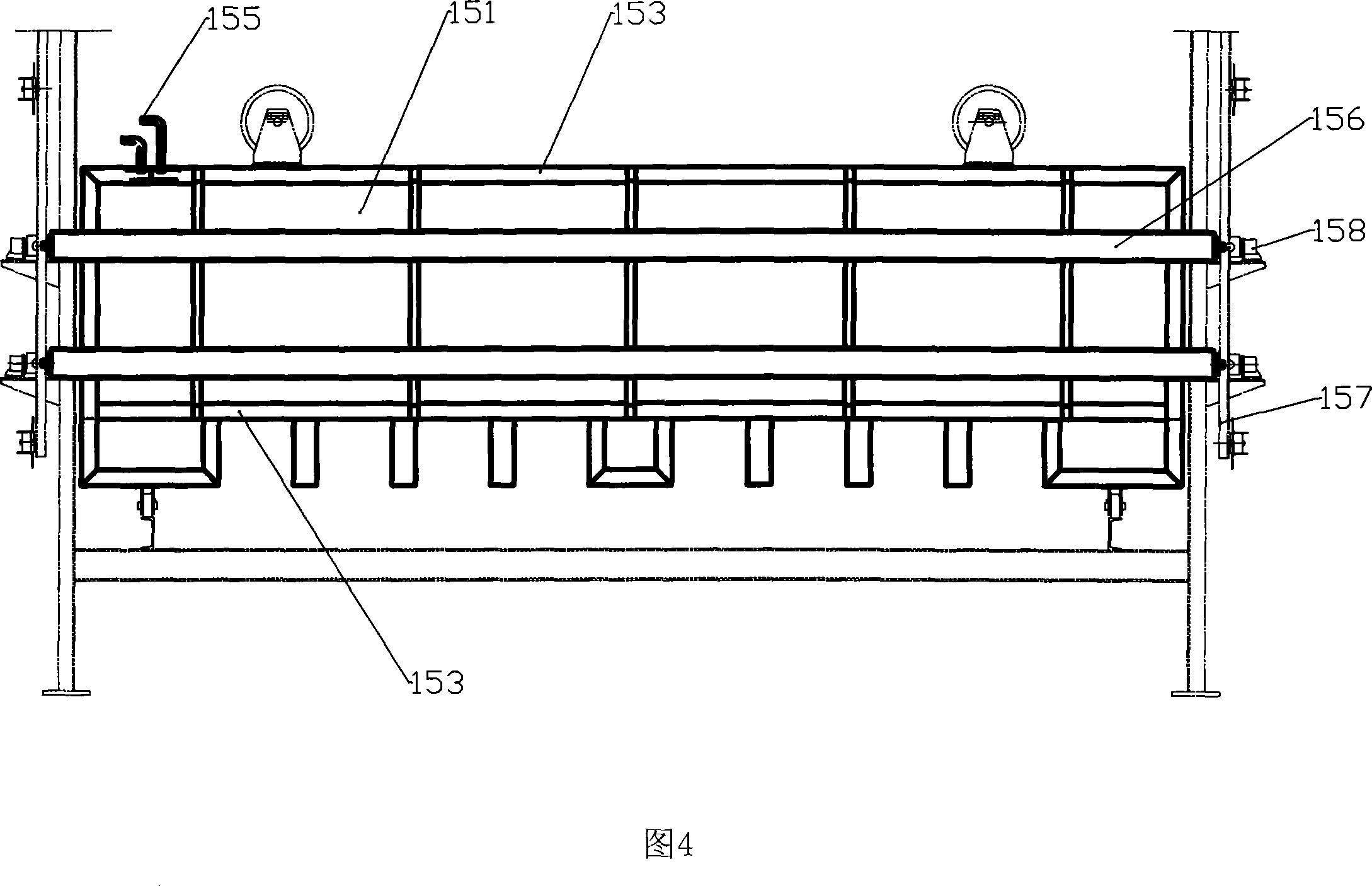

[0025] The multifunctional heating furnace of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

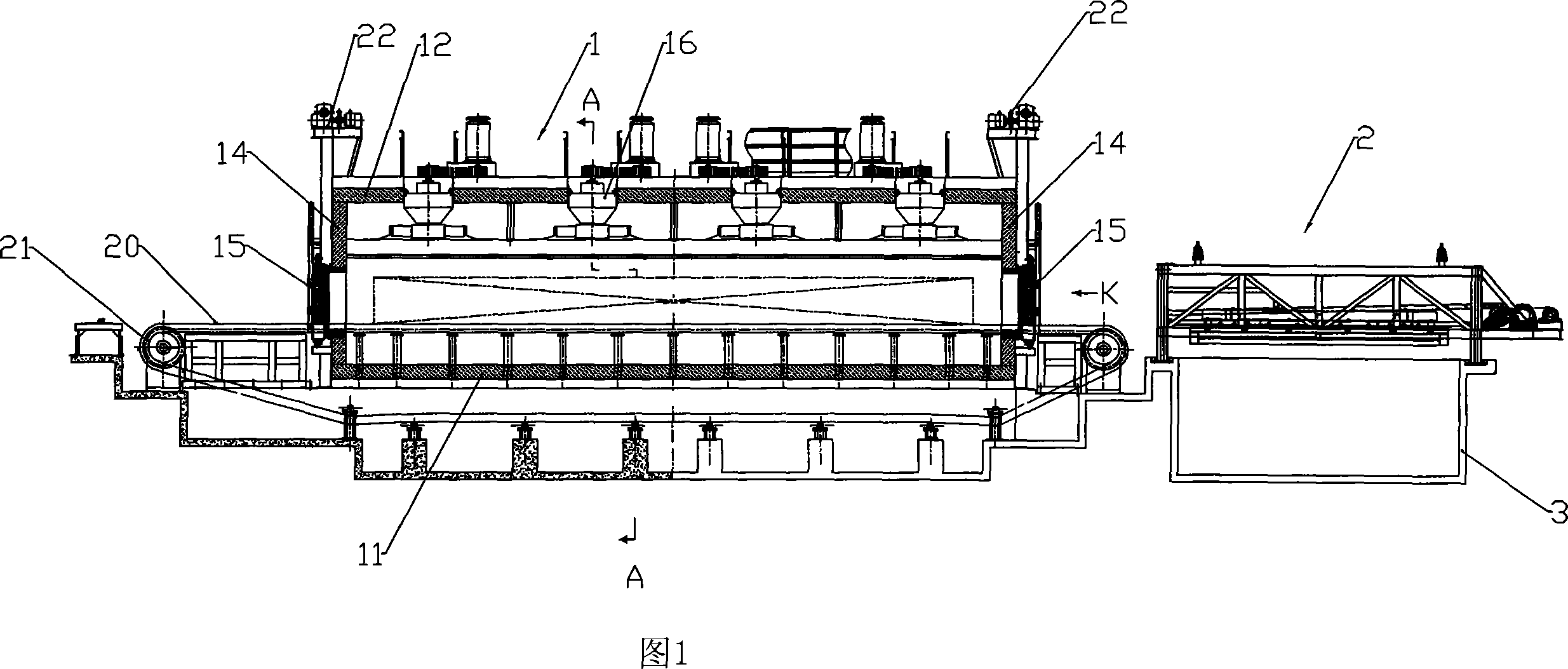

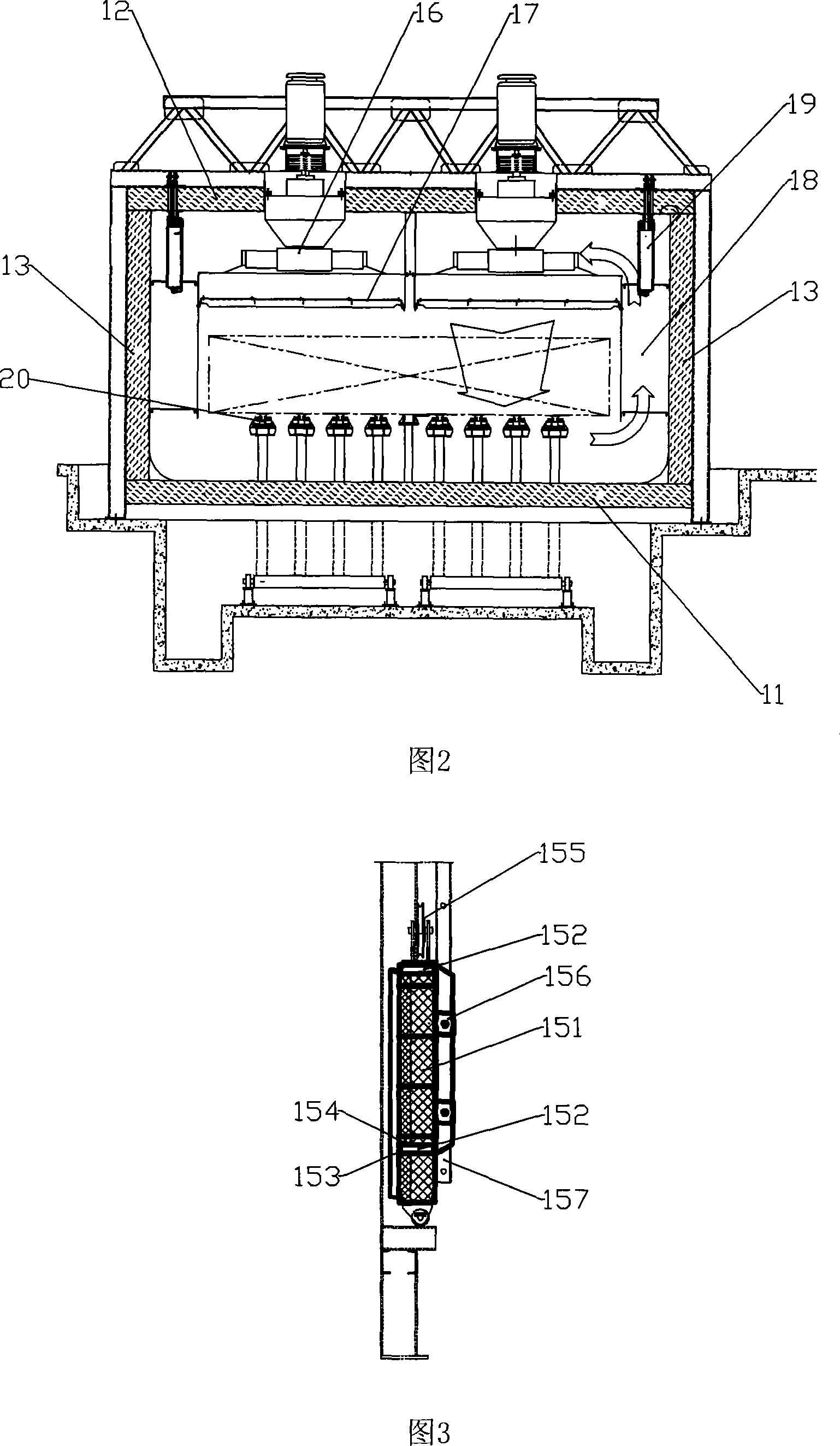

[0026] As shown in FIG. 1 , the multifunctional heating furnace includes a furnace body 1 , a quenching transfer mechanism 2 and a quenching pool 3 .

[0027] As shown in FIGS. 1 and 2 , the furnace body 1 is composed of a furnace bottom 11 , a furnace roof 12 , left and right side walls 13 , and front and rear walls 14 . The outer layer of the furnace body is made of 4mm ordinary steel plate welded with a large profile steel frame, the inner lining of the furnace body is 2mm 1Cr13 steel plate, and the lining plate of the furnace bottom is 4mm thick 1Cr13 plate to increase the strength of the furnace bottom lining plate. The insulation material aluminum silicate fiber felt + rock wool board is filled between the inner and outer steel plates of the furnace, with a total thickness of 300mm, which is called t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com