Automatic on-off for arc gate

An automatic switch and gate technology, which is applied in the field of gates, can solve problems such as unbalanced foundation force points, high support arms and hinges, and inability to use energy, so as to simplify difficulty and cost, increase anti-pressure reinforcement, and save energy and power. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

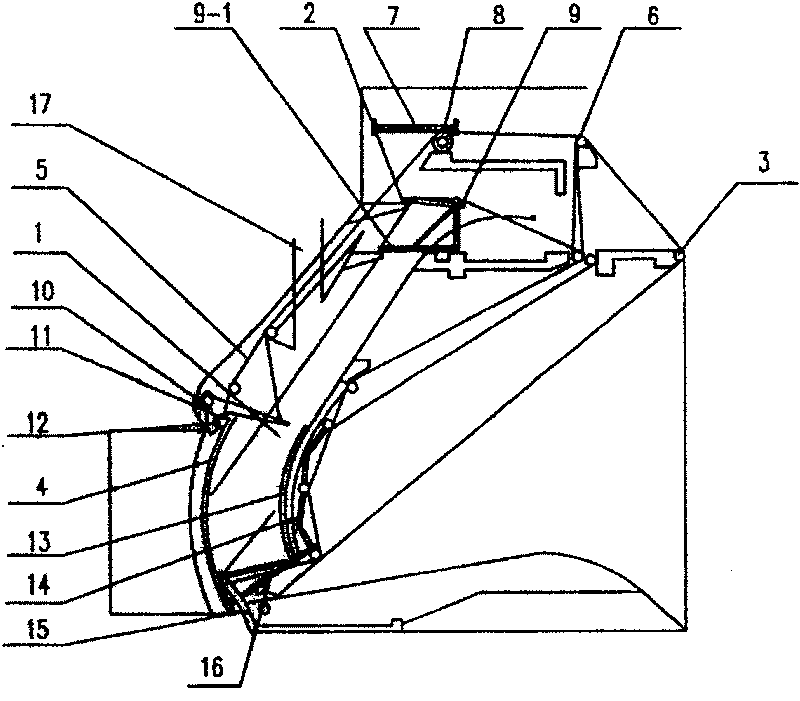

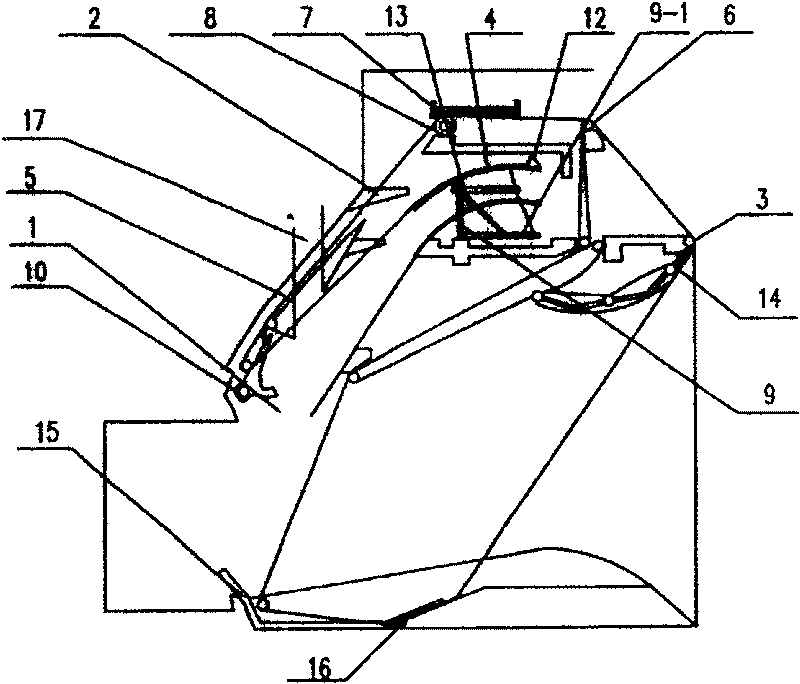

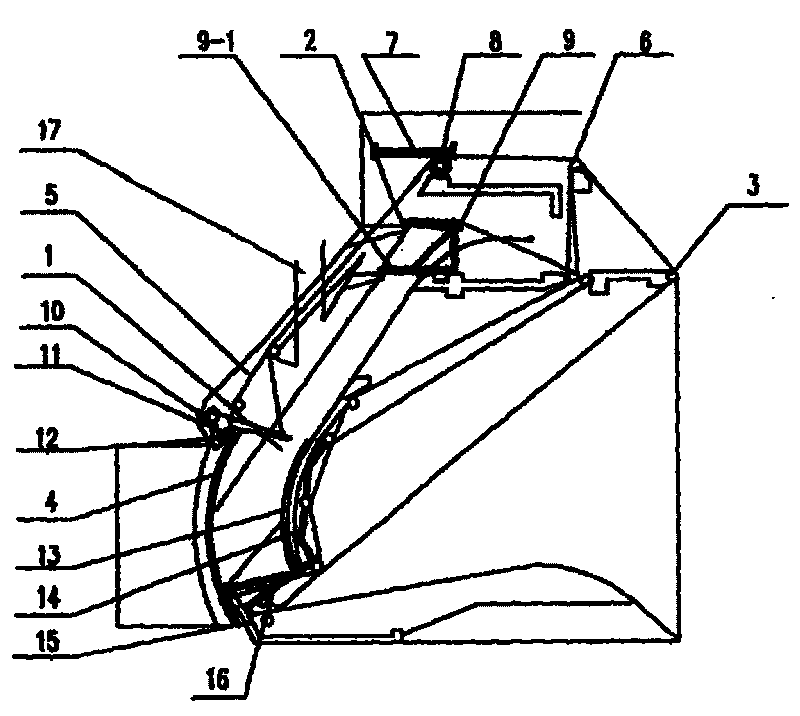

[0017] like figure 1 , figure 2 As shown, an arc gate automatic switch of the present invention includes a water storage chamber 1, a frame 2, a pulley 3, a gate 4, a steel cable 5 and an automatic retraction device 6 connected to the steel cable 5, and at the turning point of the steel cable 5 A fixed pulley is provided, a jack horizontal start switch 7 is set on the frame 2, a gear transmission mechanism 8 is connected to the jack horizontal start switch 7, the transmission mechanism 8 is connected with the cable automatic retraction device 6, and a lever is also provided on the frame 2 The starter 9 and the gear, the lever starter 9 is set as a four-bar mechanism, the lever starter 9 is arranged above the gate 4, and the gate 4 is provided with a block 10, the block 10 has a built-in card slot 11, and the steel cable 5 Connected with the cable automatic retraction device 6, the upper end of the gate 4 is provided with a protrusion 12, which is engaged with the slot 11 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com