Methods and apparatus for porosity measurement

A device, a technique for decay slope, applied in measurement devices, permeability/surface area analysis, suspension and porous material analysis, etc., can solve problems such as difficult transfer of technology to manufacturing environment, and achieve extended life, simple method configuration, and simplification The effect of the calibration and inspection process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Technical effects of the present invention include nondestructively measuring the porosity of composite structures and / or generating digital imaging showing the porosity of composite structures.

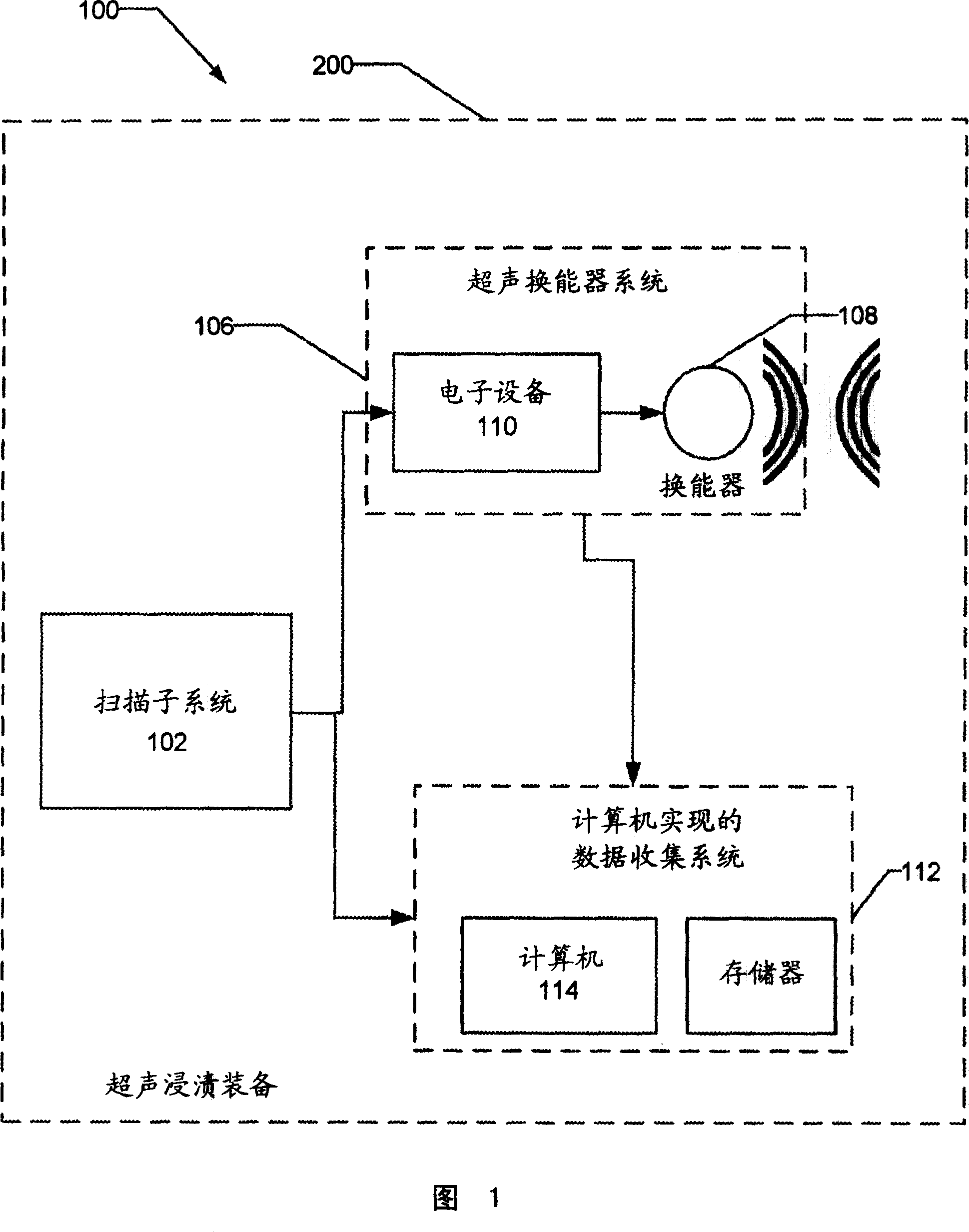

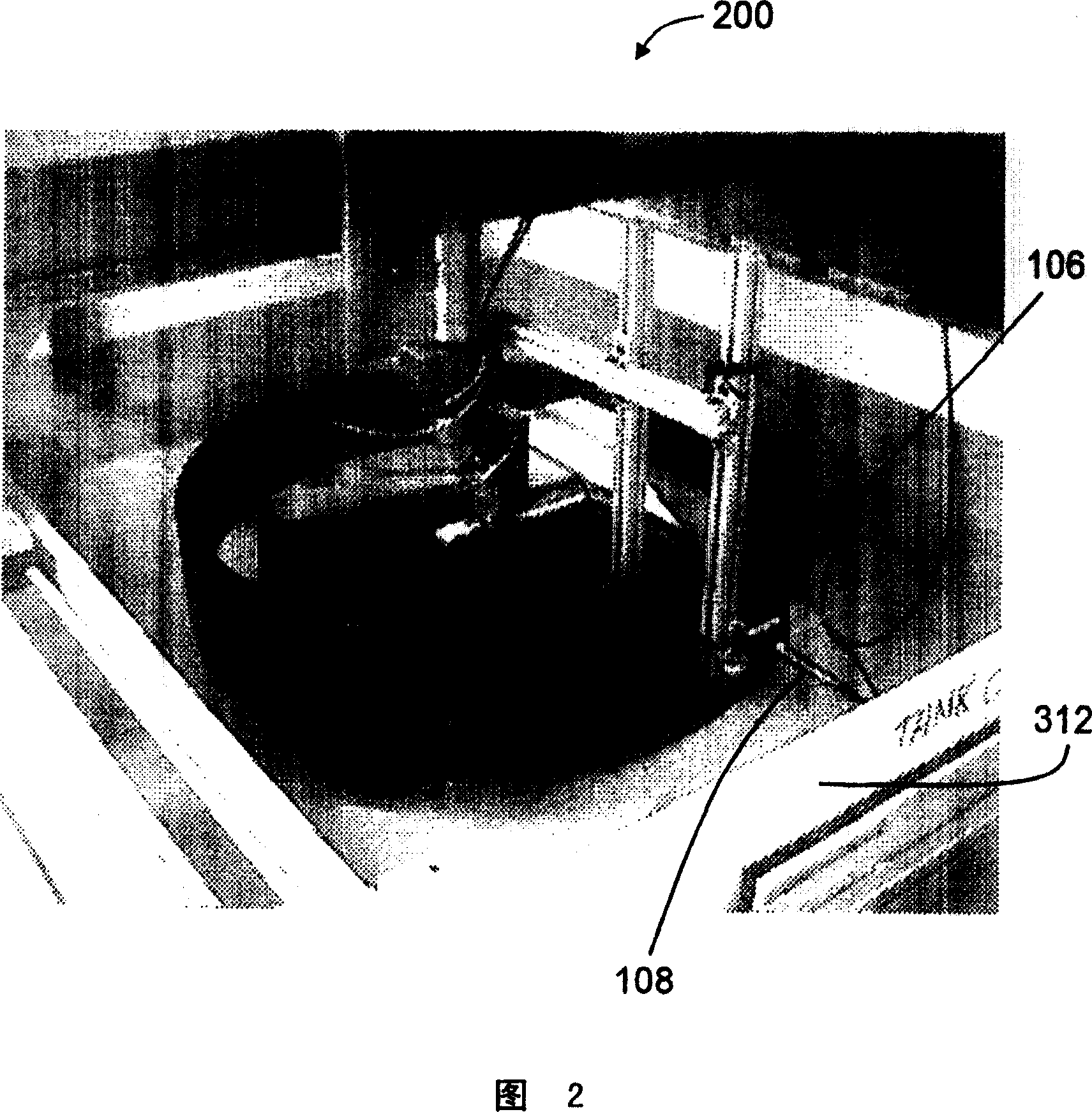

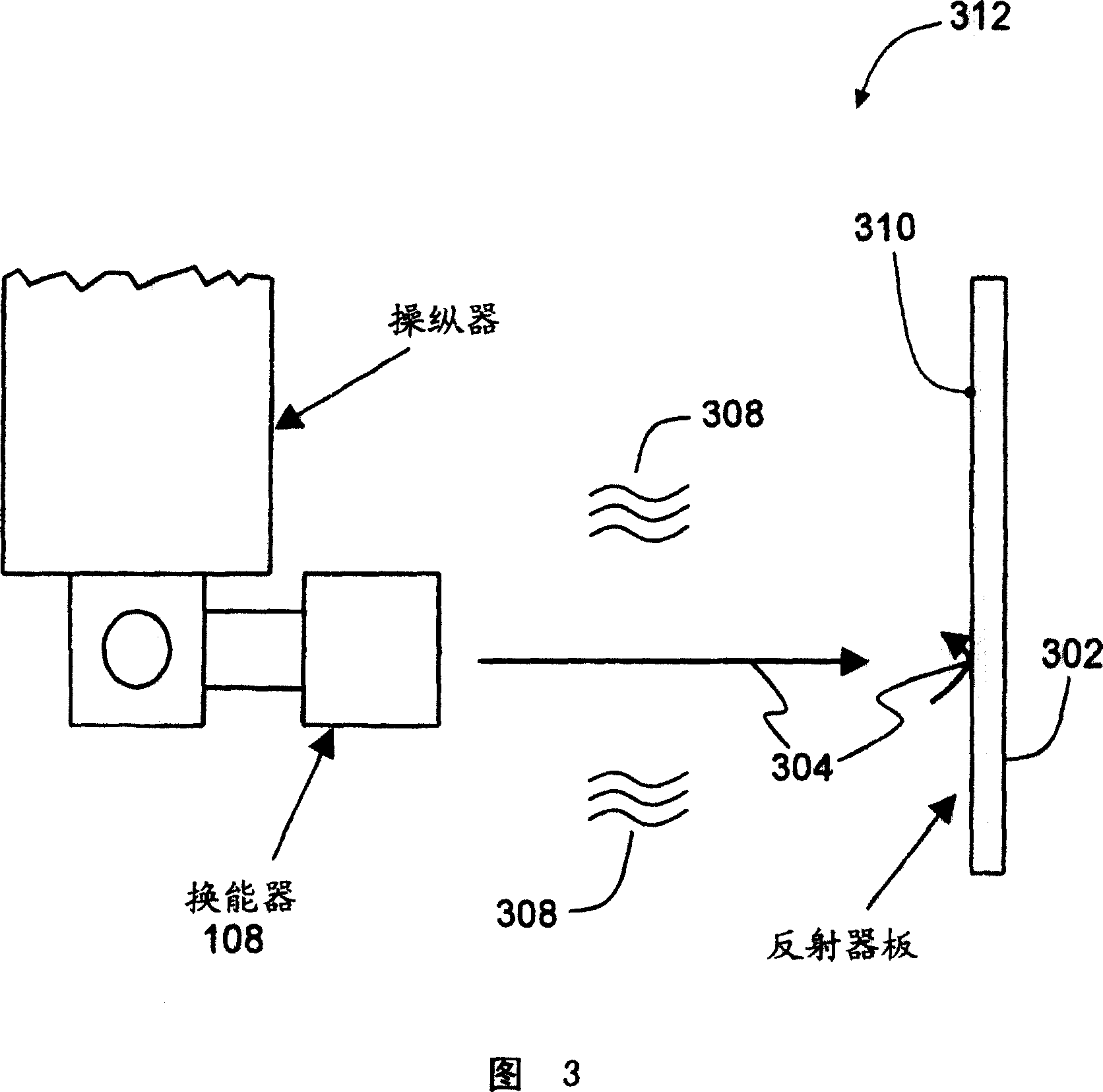

[0021] Some configurations of the present invention use a porosity measurement method that utilizes standard ultrasonic immersion equipment similar to that used to inspect metal forgings. Such equipment is readily available for inspecting composite structures and is produced by many companies, although the computer subsystem of the readily available equipment cannot be preconfigured as described herein. In some constructions, and with reference to the example structural block diagram 100 of FIG. 1 and the physical circuit diagram of FIG. 2, there are three subsections of the ultrasonic impregnation apparatus 200, namely

[0022] (a) scanning system 102 configured to position transducer 108 for transmitting and collecting ultrasound data,

[0023] (b) an ultrasound transducer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com