Adjustable optical axis reflector box

An adjustable mirror technology, applied in the optical field, can solve the problems of high manufacturing cost, limited installation position, long optical path, etc., and achieve the effect of low production cost, convenient adjustment and fast adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

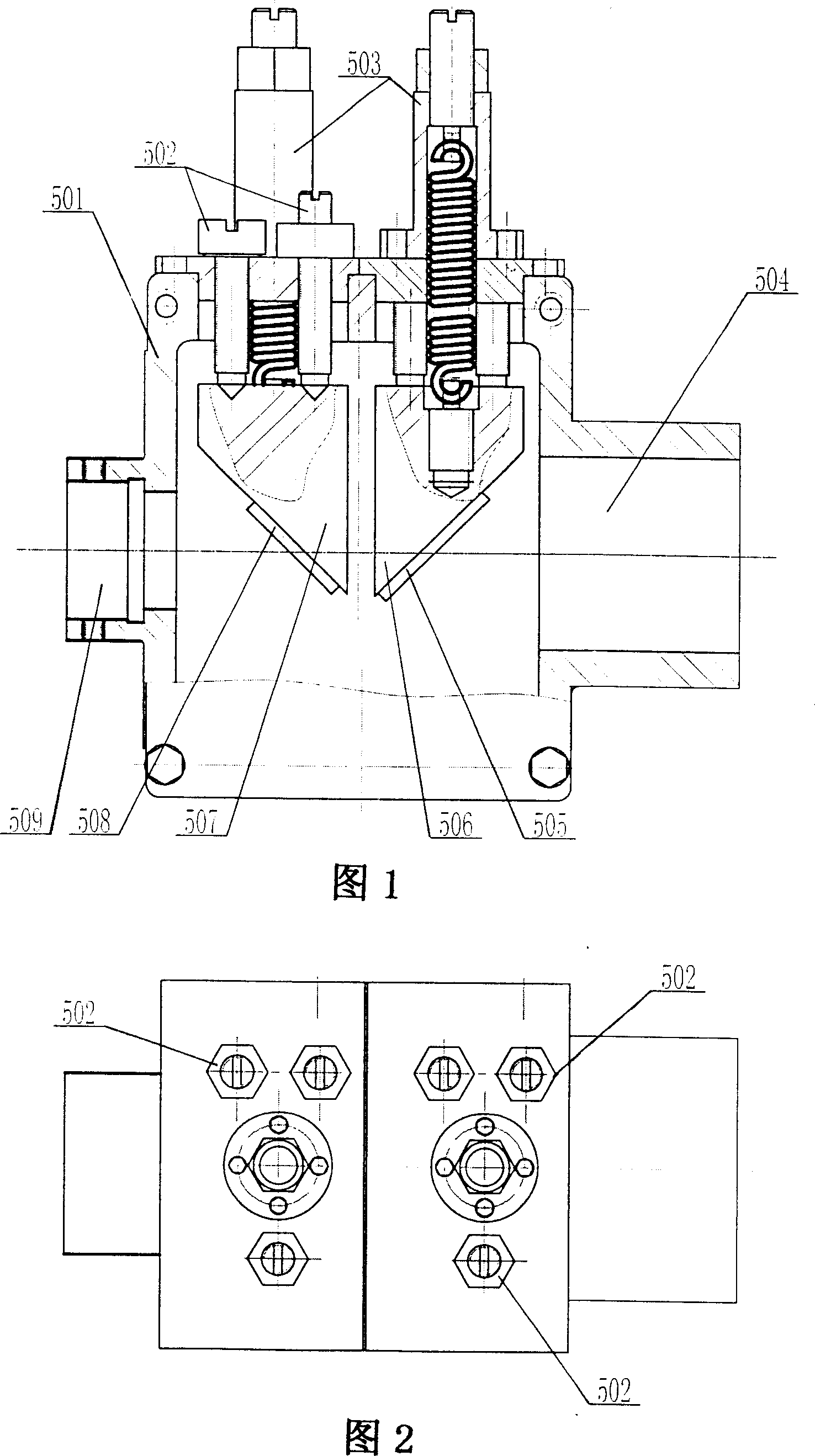

[0010] Referring to Fig. 1, Fig. 2, the adjustable optical axis reflector box of the present invention has a casing 501 with incident light through hole 509 and exit light through hole 504, and incident light through hole 509 and exit light through hole 509 and exit light in casing 501 A pair of optical surface incidence / reflection mirrors is arranged at the corresponding place of the through hole 504, wherein the light incidence mirror 508 is used to reflect the optical signal incident by the light projector outside the mirror box onto the coating comparison sheet to form an optical emission path for emitting the optical signal; The mirror 505 is used to reflect the optical signal projected on the coating comparison sheet to the light receiver outside the mirror box, forming an optical reflection path for outputting the reflected optical signal. What is connected with light incident mirror 508 is mirror holder 507, and the mirror holder that is connected with light reflection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com