Developing box

A developing cartridge and developing agent technology, applied in the direction of instruments, electrical recording process equipment using charge patterns, optics, etc., can solve the problems of increasing workers and increasing production costs, and achieve simplified assembly procedures, beautiful appearance, and labor saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

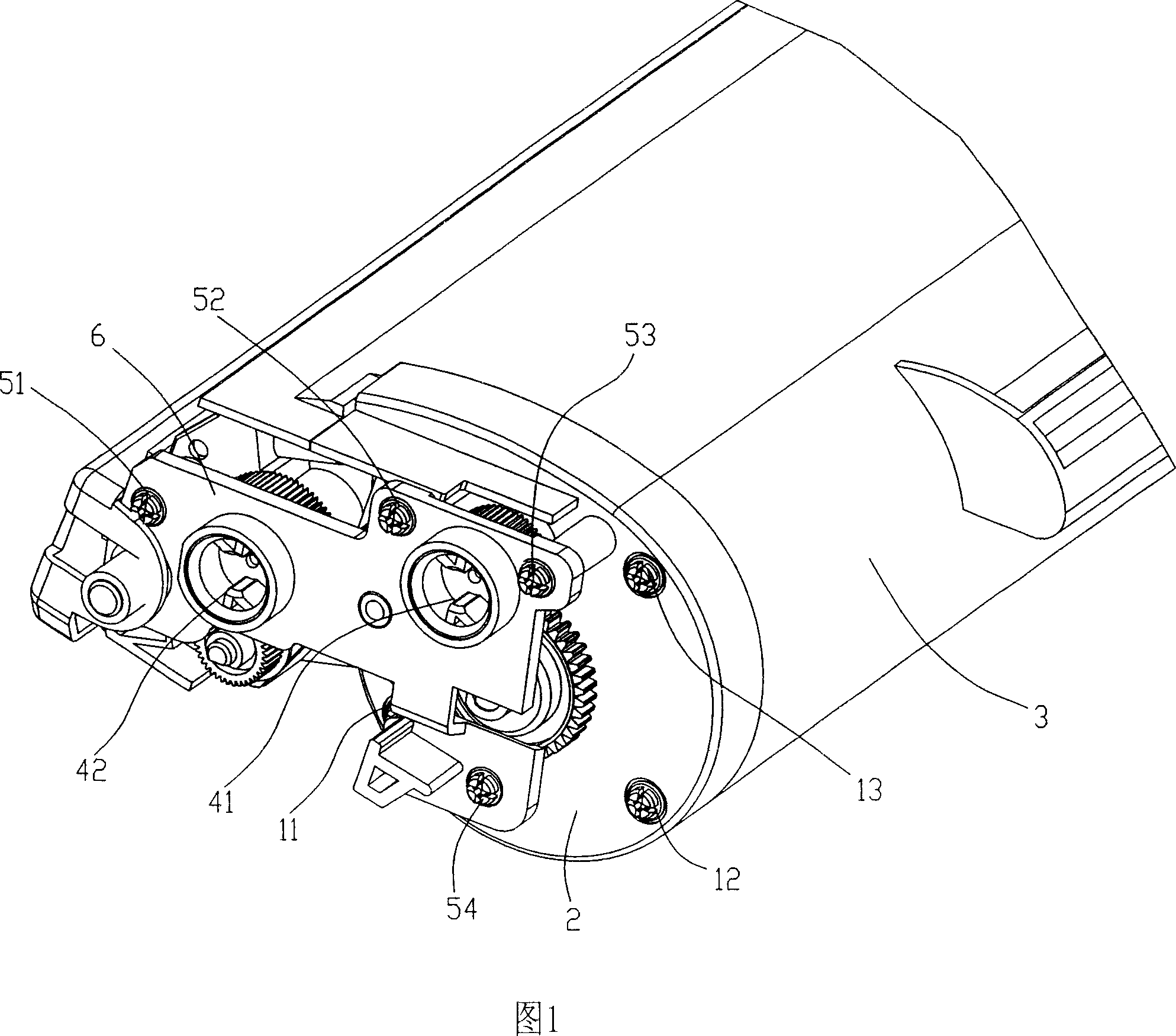

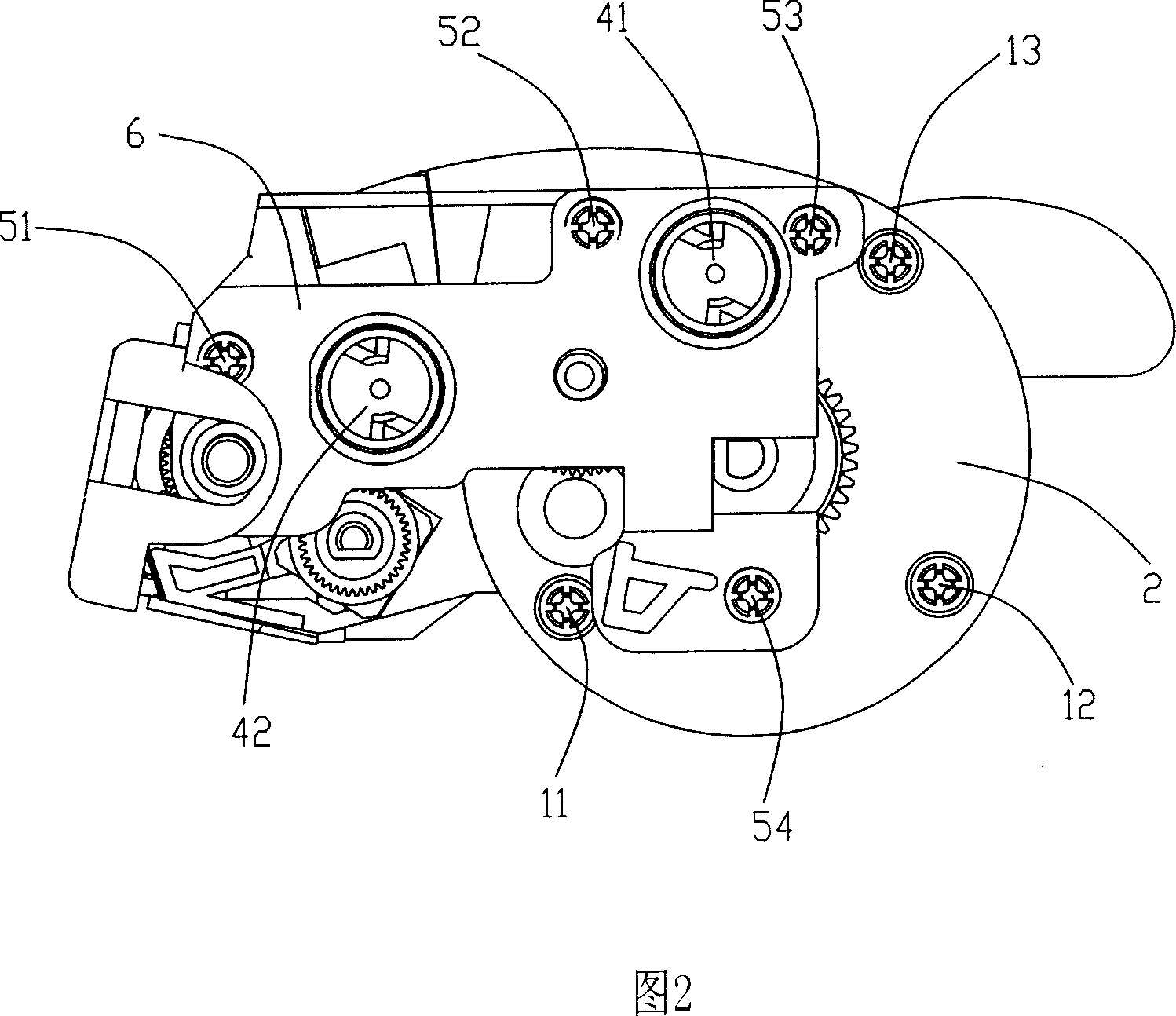

[0015] As shown in Figures 1 and 2, the developing cartridge 3 includes a box body and a side end cover with a powder bin and a developing device, a developer stirring device located in the powder bin, a powder feeding roller for feeding the developer to the developing roller, The developing roller used to develop the electrostatic latent image on the photoreceptor is used to control the limit sheet behind the developer layer on the developing roller. The gear sets at each roller end outside the side end cover are provided with drive positions with power ports.

[0016] The special feature is that the shell of the box body in the direction perpendicular to the side end cover is arc-shaped, and the box body and the side end cover are connected into one body.

[0017] There may be two or more power ports.

[0018] For example, the double drive power receiving ports 41, 42 are located on the gear cover 6, and the gear cover 6 is connected to the right end cover 2 with screws 51, ...

Embodiment 2

[0020] In Embodiment 1, the right end cover 2 is connected to the powder bin by screws.

[0021] The left end cover of the developer box and the powder bin can also be connected in the same way.

[0022] Or, the left end cover, the right end cover and the powder bin of the developing cartridge can be connected in the same way simultaneously.

[0023] Alternatively, the connection mode between the end cover and the powder bin can be a lock pin or a lock.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com