Rectifying device of bulking machine

A technology of rectifying device and extruder, which is applied in the fields of feed and food forming, food science, etc., can solve the problems of the appearance of the product being too different in length and thickness, the appearance quality of the product, and the incomplete curing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] specific implementation plan

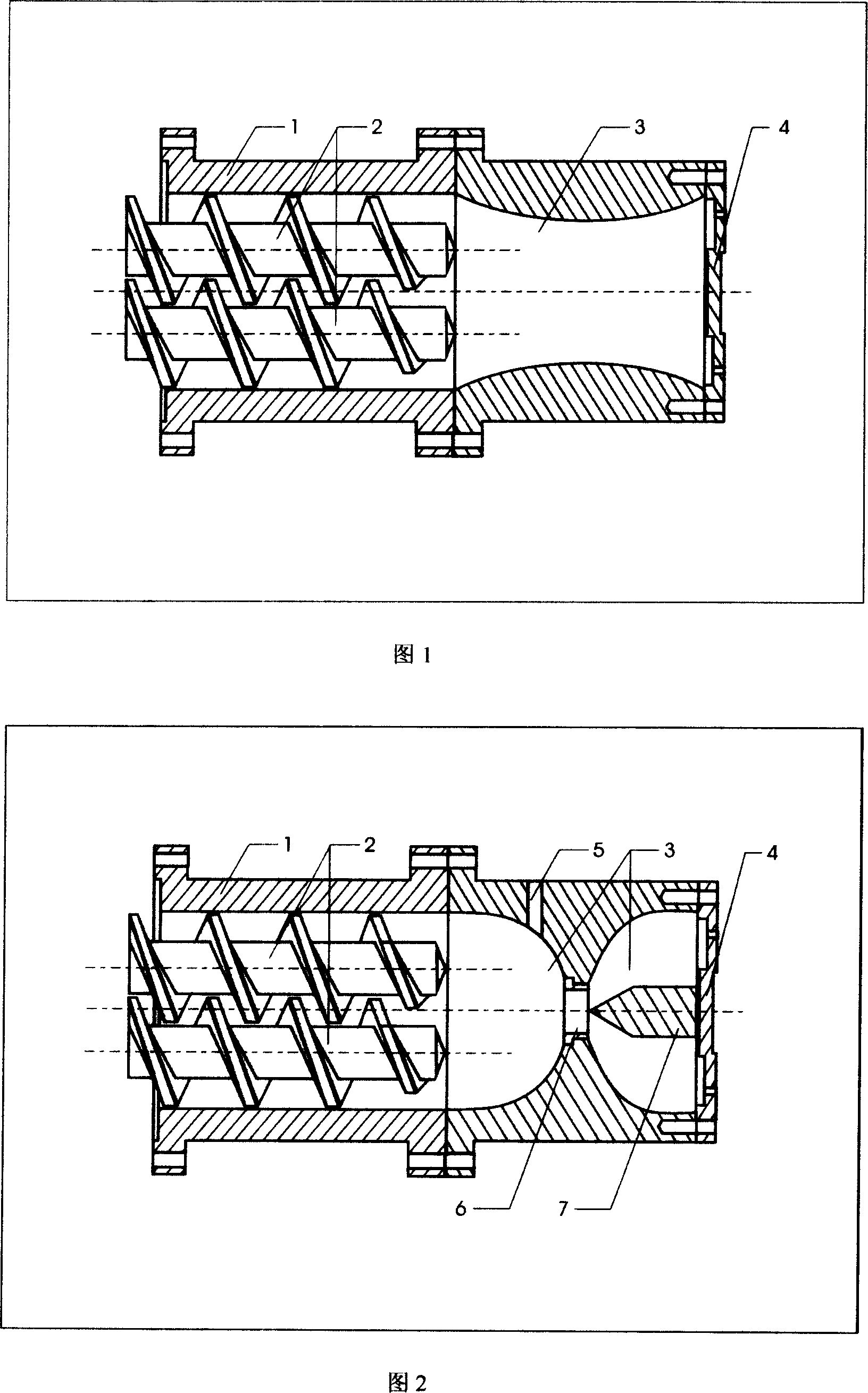

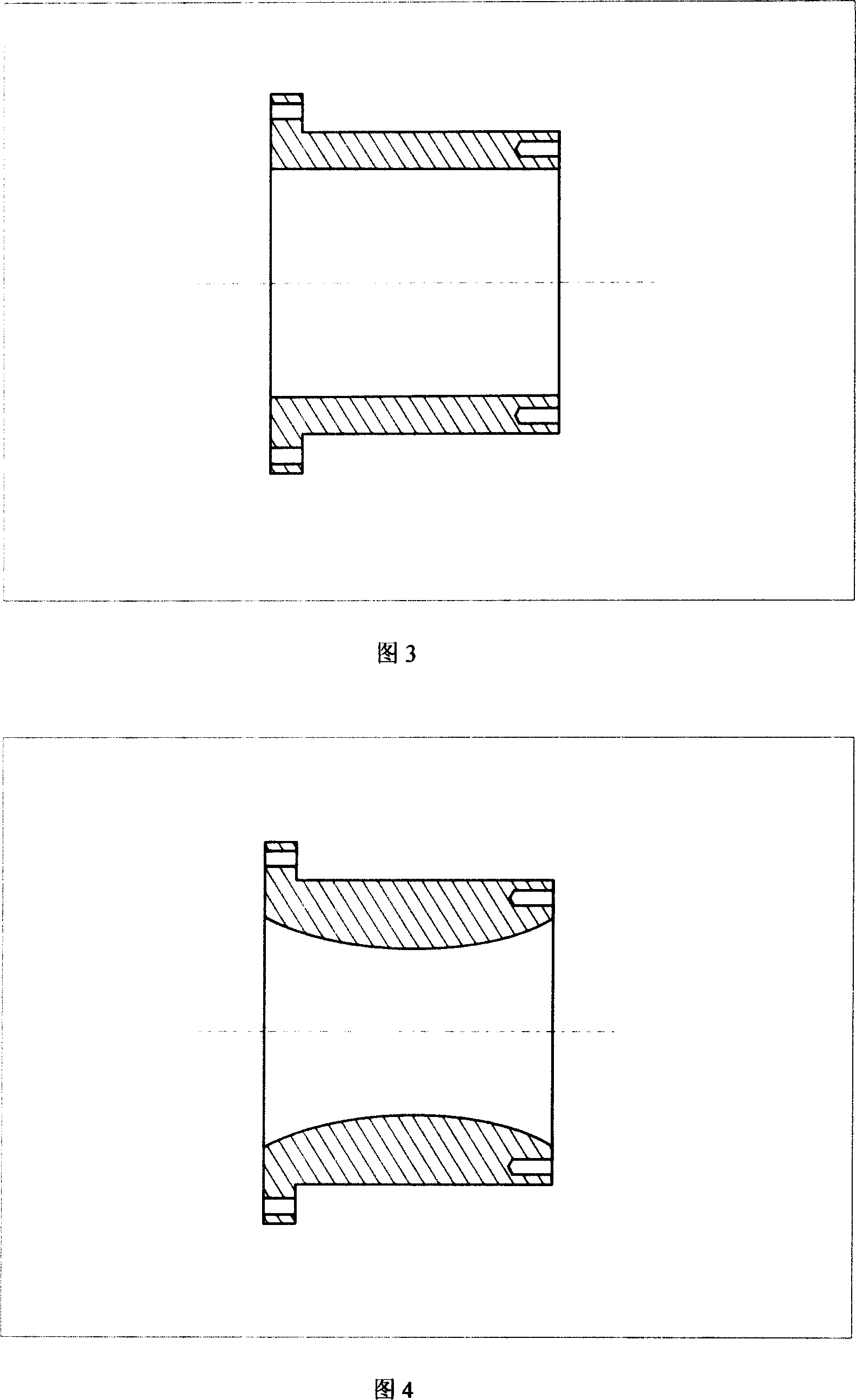

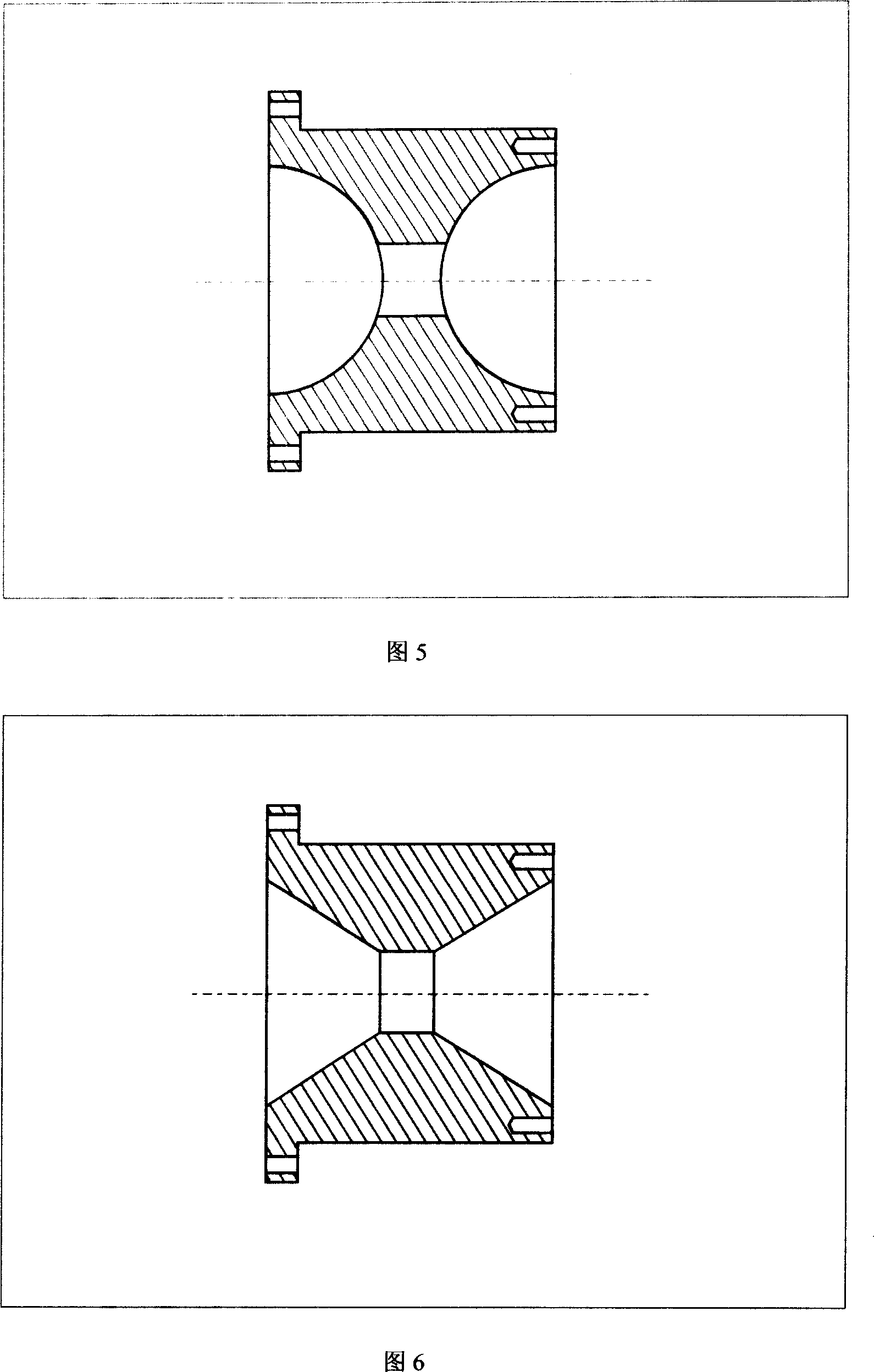

[0049] Referring to Fig. 1 and Fig. 2, it is a puffing machine (extruder) rectifying device, which is mainly composed of an expanding chamber 1, a screw 2, a rectifying chamber 3, a mold 4, etc., and one end of the rectifying chamber 3 is fixed at the outlet of the puffing chamber 1, The mold 4 is fixed at one end, and the rectifying cavity 3 is the material channel, which can be in various arbitrary shapes and sizes, as shown in Figures 3 to 9, and the length (L) of the rectifying cavity can be set to any size.

[0050] The present invention is not limited to the above example, as shown in Figure 2, a splitter plate 6 is set in the middle of the rectification cavity 3, or a splitter cone 7 is set at the outlet terminal of the rectification cavity 3, or any one of the above two devices or a combination thereof are set , the splitter plate 6 is provided with a through hole or a plurality of through holes, and the holes can be designed in va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com