System and method for preparing large-particle anhydrous sodium sulphate as byproduct of nitrate-containing brine

A preparation system, a technology of nitrate brine, applied in the direction of alkali metal sulfite/sulfate purification, etc., can solve the problems of large energy consumption, achieve the effect of improving quality, optimizing the end point of salting-out reaction, and reducing residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

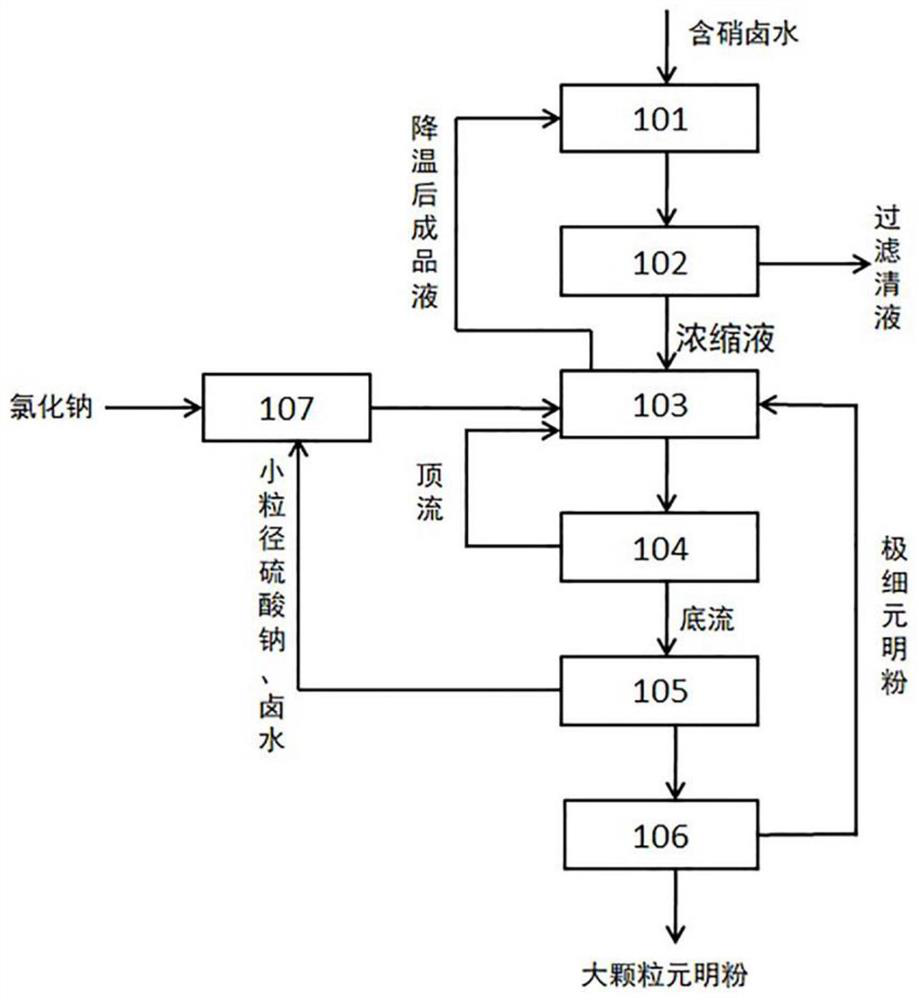

[0037] A kind of preparation system of the by-product large particle sodium sulfate containing nitrate brine, such as figure 1 As shown, it includes a membrane concentration unit 102 , a continuous flow salting out unit 103 , a suspension classification treatment unit 104 , a centrifugal unit 105 , a drying unit 106 and a sodium chloride suspension mixing unit 107 .

[0038] The membrane concentration unit 102 is provided with a nitrate-containing brine liquid inlet, a sodium sulfate concentrated solution outlet and a filtered clear liquid outlet, and is used for concentration of nitrate-containing brine;

[0039] The continuous flow salting-out unit 103 is provided with a sodium sulfate concentrated solution inlet, a top flow stream inlet, a sodium chloride suspension mixed liquid inlet, a sodium sulfate suspension material outlet and a finished product liquid outlet, and is used for salting out to prepare sodium sulfate Particle; the sodium sulfate concentrated solution inle...

Embodiment

[0071] Nitrate-containing brine produced by a domestic chlor-alkali factory: NaCl content 200g / L, Na 2 SO 4 The content is 42-67g / L.

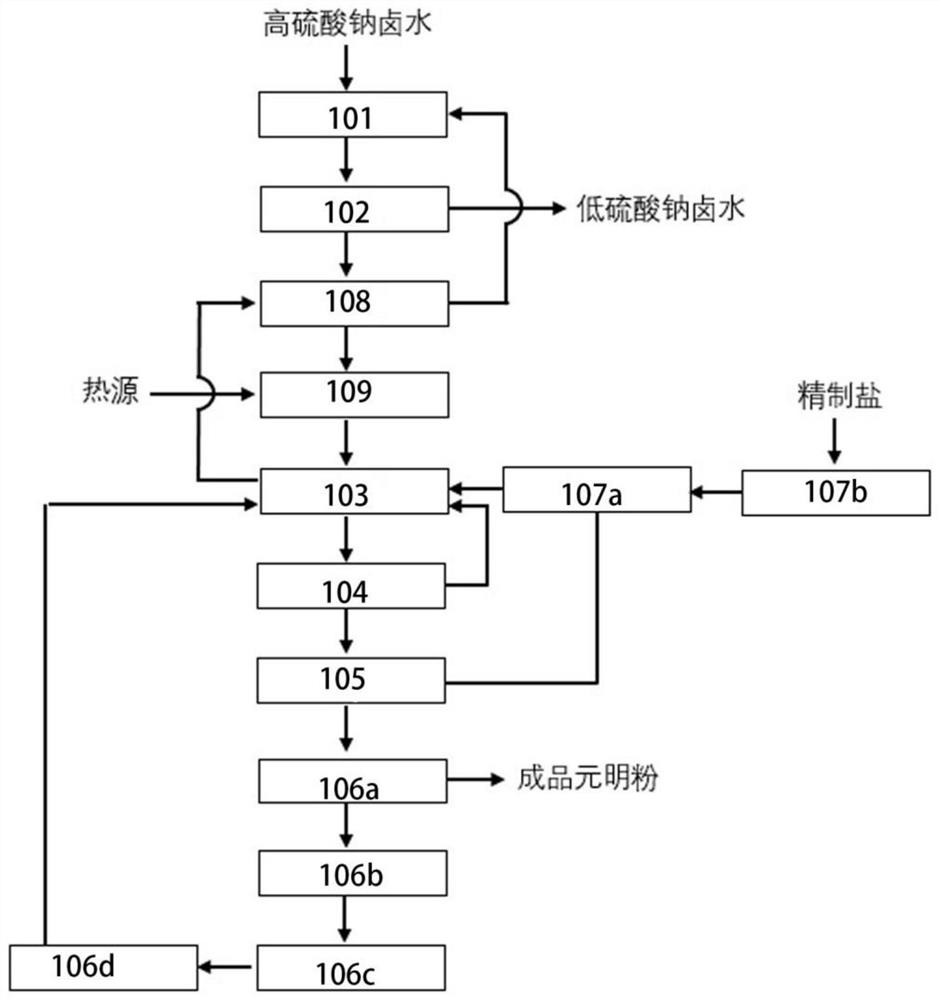

[0072] The preparation system of the present invention containing nitrate brine by-product large particle sodium anhydride is as follows figure 2 As shown, the treatment capacity of nitrate-containing brine is about 1125m 3 / day, the output of large particle sodium sulfate is 4320kg / day.

[0073] a), after the nitrate-containing brine is collected, it is transported by the water delivery pump, and transferred to the water distribution tank of the water distribution unit 101 of the preparation system of the by-product of the nitrate-containing brine, which is a by-product of large grains of sodium sulfate. In the water distribution tank, the two are mixed to complete the ratio of sodium sulfate content in the brine to obtain high-nitrate brine with a NaCl content of 190-200g / L, Na 2 SO 4 content of 70-90g / L; the high-nitrate brine is trans...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com