Preparation method of baked corn, product and application of baked corn in livestock and poultry feed

A corn and baking technology, which is applied in the fields of application, animal feed, animal feed, etc., can solve the problems that corn cannot meet the market demand, the market price of corn is rising, and humans and animals compete for food, etc. It is beneficial to digestion and absorption, beneficial to digestion and absorption, Digestion-promoting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The embodiment of the present invention provides a preparation method of roasted corn, comprising the following steps:

[0021] After removing impurities from the corn, soak it in water; transfer the soaked corn to the roaster for segmental heating and roasting, the inlet temperature is 100-160°C, the baking temperature is 140-280°C, the outlet temperature is 60-150°C, and at the same time stirring; cooling the roasted corn to obtain the finished product.

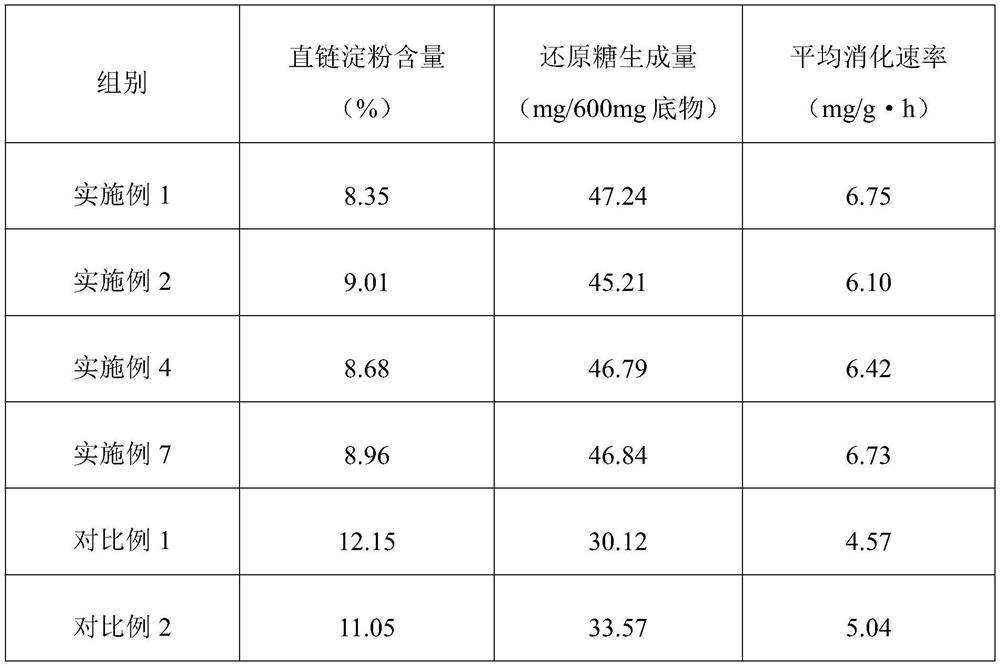

[0022] In the above-mentioned examples, the preparation method has a simple process, and high-quality corn that is basically free of impurities can be obtained after impurity removal and screening. During the heating and roasting process at 140-280°C, heat, humidity, pressure and various mechanical actions are combined. , making the surface of corn caramelized, has obvious food-attracting effect, can effectively improve the degree of gelatinization of starch in baked corn, destroy and soften the fiber structure of pa...

Embodiment 1

[0036] A method for preparing roasted corn, comprising the following steps:

[0037] Screen the corn through a vibrating sieve, remove stones by dry method, and then pass through permanent magnetic cylinder magnetic separation to remove magnetic metal substances to obtain corn that is basically free of impurities, and then soak it in water. The weight ratio of corn to water is 10:2. Soaking time is 25min;

[0038] The soaked corn is put into the roaster for heating and roasting in sections. The inlet temperature is 130°C, the roasting temperature is 205°C, the roasting time is 17 minutes, and the outlet temperature is 100°C. At the same time, the screw speed is 105r / min. Stirring ;

[0039] The roasted corn is cooled for 10 minutes, the moisture content of the cooled corn is kept at 10%, and then crushed, and the crushed corn is passed through a 1.5mm sieve, and the finished roasted corn is obtained after packaging.

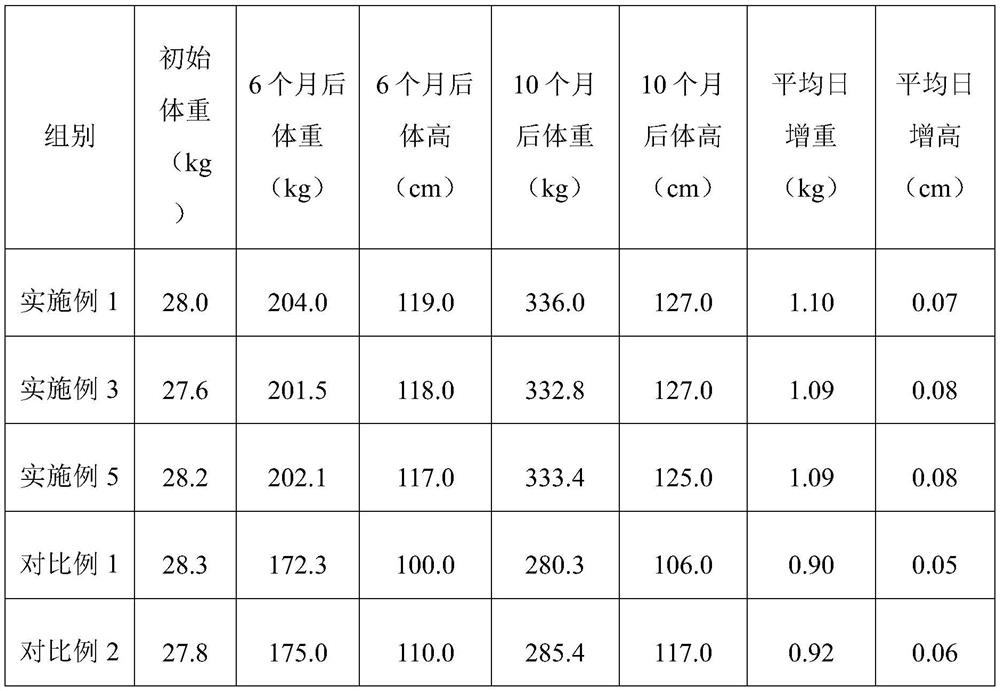

[0040] The baked corn prepared by the above method is use...

Embodiment 2

[0042] A method for preparing roasted corn, comprising the following steps:

[0043]Screen the corn through a vibrating sieve, remove stones by dry method, and then pass through permanent magnetic cylinder magnetic separation to remove magnetic metal substances to obtain corn that is basically free of impurities, and then soak it in water. The weight ratio of corn to water is 10:1. Soaking time is 40min;

[0044] The soaked corn is put into the roaster for heating and roasting in sections. The inlet temperature is 100°C, the roasting temperature is 130°C, the roasting time is 30min, and the outlet temperature is 60°C. At the same time, the screw speed is 60r / min. Under the condition of stirring ;

[0045] The roasted corn is cooled for 5 minutes, the moisture content of the cooled corn is kept at 12%, and then crushed, and the crushed corn is passed through a 1.5mm sieve, and the finished roasted corn is obtained after packaging.

[0046] The baked corn prepared by the above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com