Nozzle for preparing synthesized gas by partial oxidation of liquid fuel

A technology of liquid fuel and synthetic gas, applied to gas fuel burners, burners, combustion methods, etc., can solve problems such as easy leakage of the burner cooling system, leakage of the burner cooling system, and short service life of the burner. With the effect of convenient maintenance, improved atomization performance and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

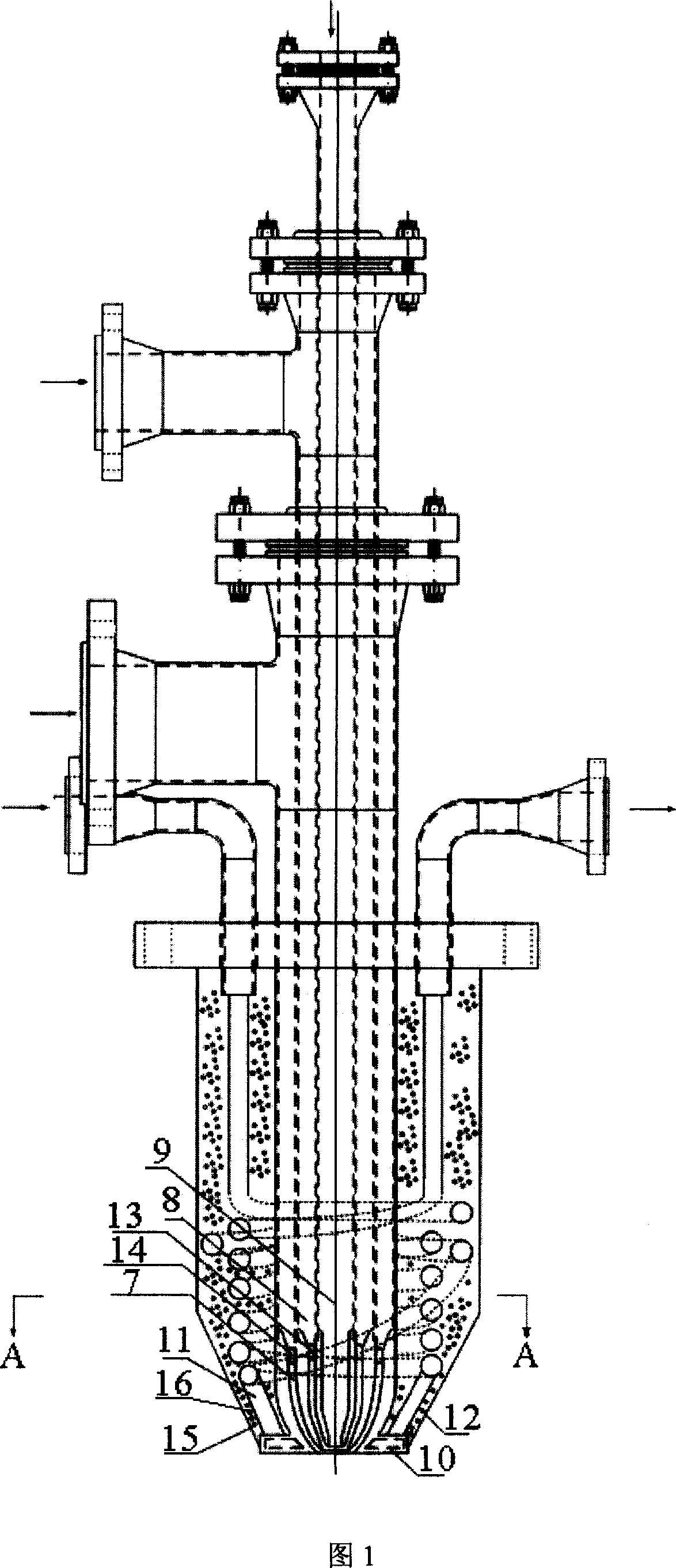

[0048] After the above-mentioned burner is installed in the gasifier disclosed in Chinese patent 98110616.1, when the fuel is a coal-water slurry with a concentration of 61% (mass %), with 98% pure oxygen as the gasification agent, the gasification result is a synthetic Effective gas composition CO+H in the gas 2 (vol%) 83.0%, ash residual carbon is 4%, and the continuous service life of the burner can reach 4 months, fully meeting the requirements of coal-water slurry gasification.

[0049] The structural parameters of said burner are as follows:

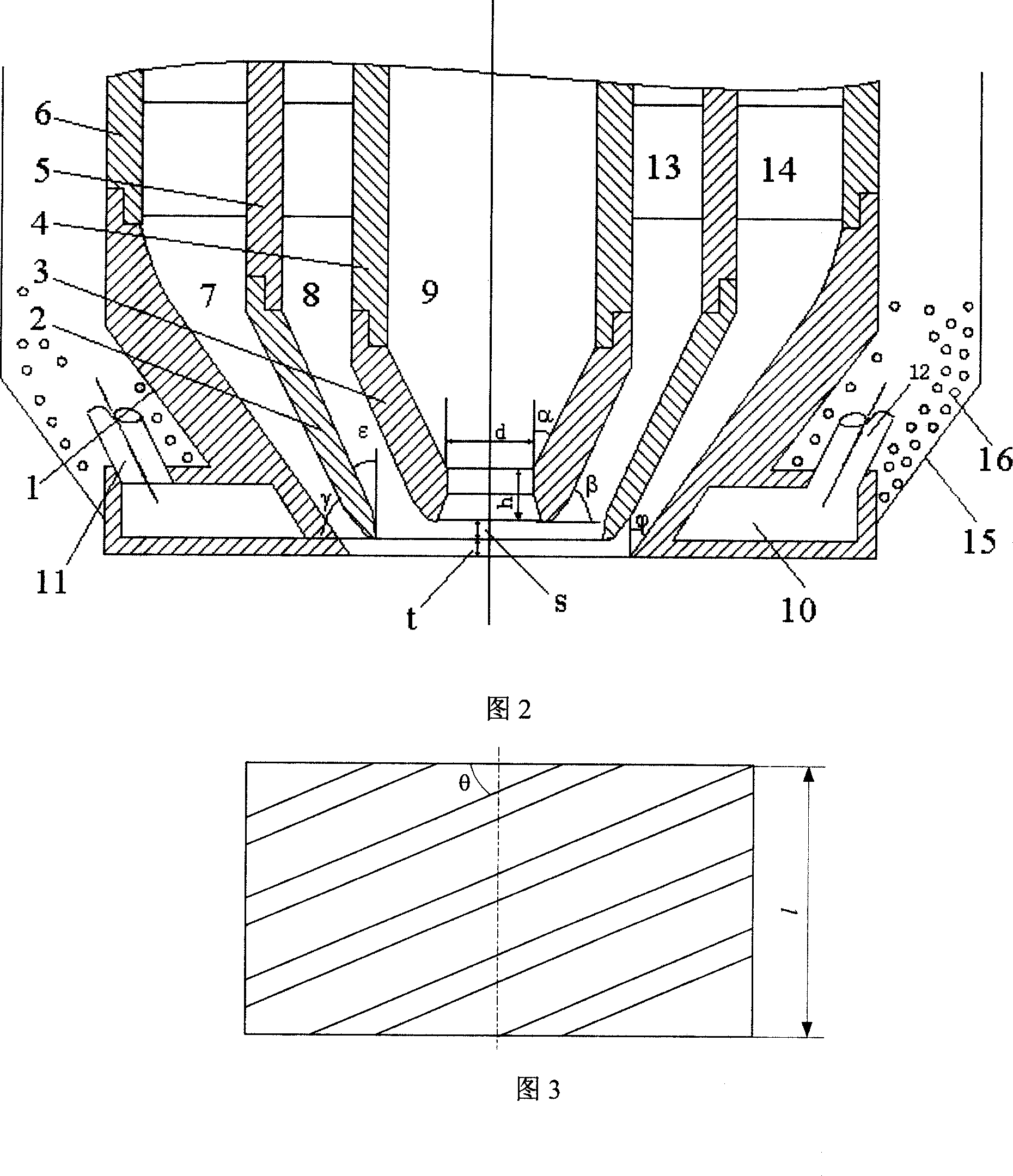

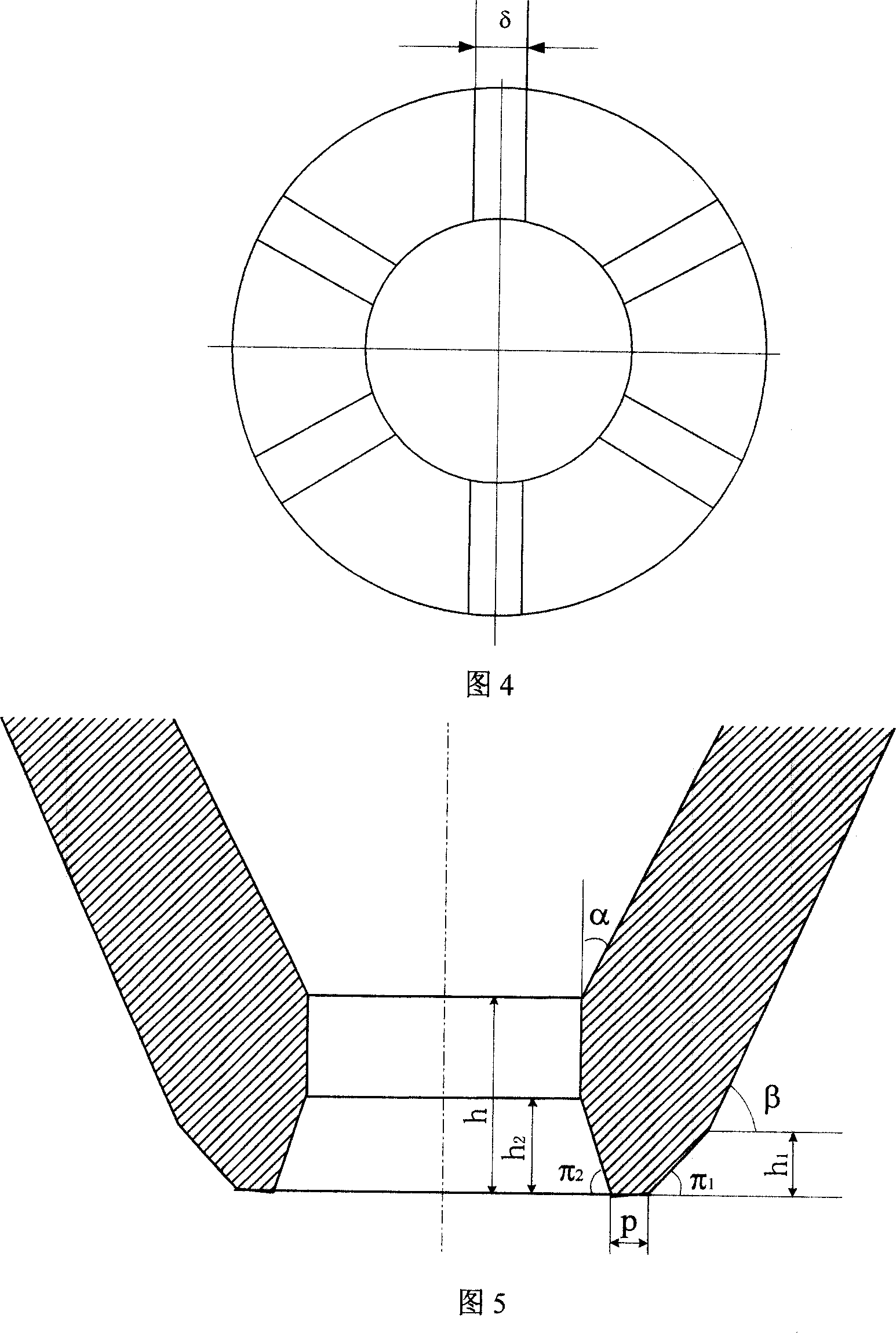

[0050] α is 5°, β is 85°; ε is 5°, γ is 40°; is 50°;

[0051] The ratio of the nozzle diameter d of the inner nozzle (3) to the height h of the nozzle straight section (301), i.e. h: d=10;

[0052] The distance s between the nozzle end face of the center nozzle (3) and the nozzle end face of the middle ring nozzle (2) is 10mm;

[0053] The distance t between the nozzle end face of the middle ring nozzle (2) and the nozzle end ...

Embodiment 2

[0061] After the above-mentioned burner is installed in the gasifier disclosed in Chinese patent 98110616.1, when the fuel is a coal-water slurry with a concentration of 63% (mass %), with 99.6% pure oxygen as the gasification agent, the gasification result is a synthetic Effective gas composition CO+H in the gas 2 (vol%) 85%, ash residual carbon is 4%, the continuous service life of the burner can reach 4 months, which fully meets the requirements of coal-water slurry gasification.

[0062] The structural parameters of said burner are as follows:

[0063] α is 20°, β is 60°; ε is 30°, γ is 50°; is 40°;

[0064] The ratio of the nozzle diameter d of the inner nozzle (3) to the height h of the nozzle straight section (301), i.e. h: d=0;

[0065] The distance s between the nozzle end face of the center nozzle (3) and the nozzle end face of the middle ring nozzle (2) is 1mm;

[0066] The distance t between the nozzle end face of the middle ring nozzle (2) and the nozzle end ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap