Multifunctional compound rheological agent and preparation method thereof

A rheological agent and multi-functional technology, applied in the field of preparation of petroleum coke powder-heavy oil-water new fuel system, to achieve the effects of low ignition temperature, complete combustion and lower exhaust gas temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

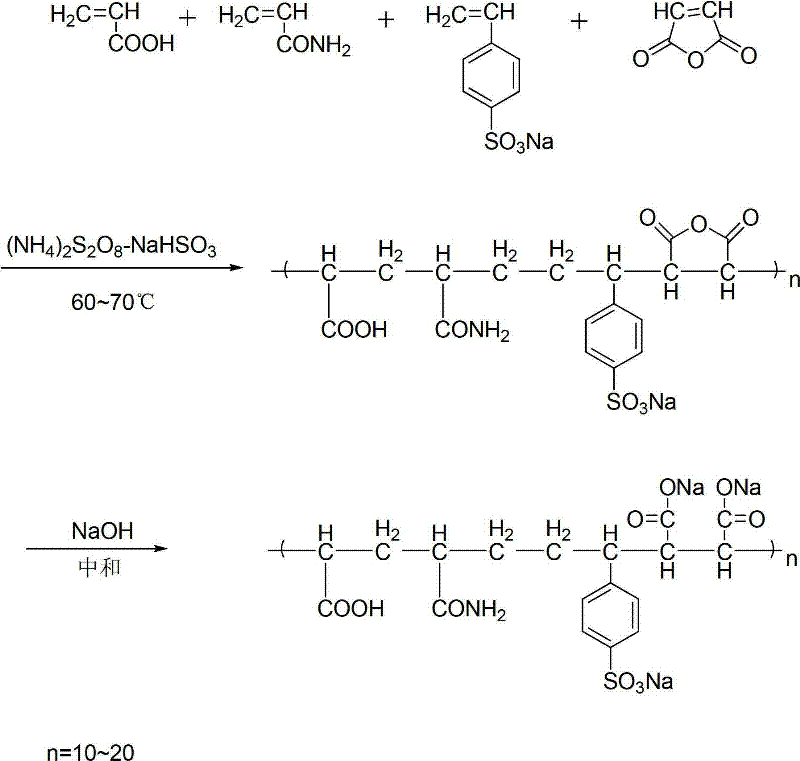

Image

Examples

Embodiment 1

[0030] Embodiment 1, the preparation method of this multifunctional composite rheological agent is:

[0031] A. Preparation of stable rheological agent

[0032] a. Weigh the raw materials according to the mol ratio of each raw material: AM: AA: BS: MA=0.2: 1: 0.03: 0.5, and take kilograms as the unit, AM14.2Kg, AA72Kg, BS6.2Kg, MA49Kg,

[0033] Get the ammonium persulfate of aforementioned raw material gross weight 0.7% that is 0.99Kg as oxygenant,

[0034] Get that 2.12Kg sodium bisulfite of 1.5% of aforementioned raw material gross weight is reducing agent,

[0035] b. Synthesis operation: Add 50% of the total weight of the aforementioned raw materials, that is, 72Kg of water in the reactor to make bottom water and MA, heat to dissolve, add sodium bisulfite and then heat up to 65°C to 70°C, and make the oxidant into 3% The aqueous solution is A drop, and AA+BS+AM is made into a 60% aqueous solution to be B drop. At the same time, A drop and B drop are added dropwise to the...

Embodiment 2

[0037] Embodiment 2, the raw material composition weight and number ratio of stable rheological agent is:

[0038] AM

AAA

BS

MA

21.3

108

0

39.2

28.4

122.4

2.06

58.8

35.5

136.8

4.12

78.4

42.5

144.0

6.18

98.0

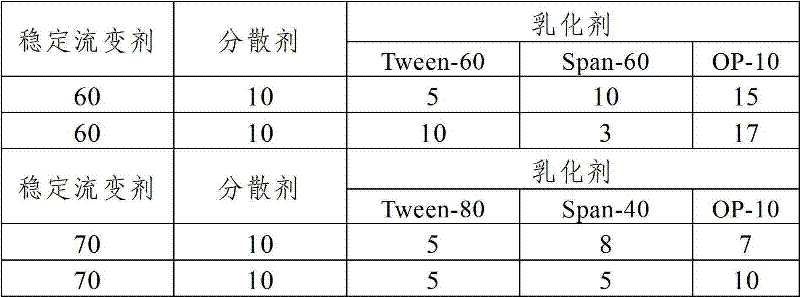

[0039] Other ratios in parts by weight of the composite rheological agent are:

[0040]

Embodiment 3

[0041] Embodiment 3, the using method of multifunctional composite rheology agent is: for making tar water slurry according to the weight and number ratio of petroleum coke powder: heavy oil: water=30:60:10, add 1.0% of tar water slurry weight The composite rheological agent is heated to 80°C and stirred for 30 minutes under the condition of a rotating speed of 1500 rpm, and the time for the tar water slurry to be stable without separation is 20 to 25 days.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com