Gas-assisted atomizing nozzle and sprayer thereof

An atomizing nozzle, gas-assisted technology, applied in the direction of liquid injection device, injection device, injection device, etc. Problems such as high energy consumption of compressed air, to achieve the effect of increasing the gas-liquid contact area, small droplet size, and increasing spray flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

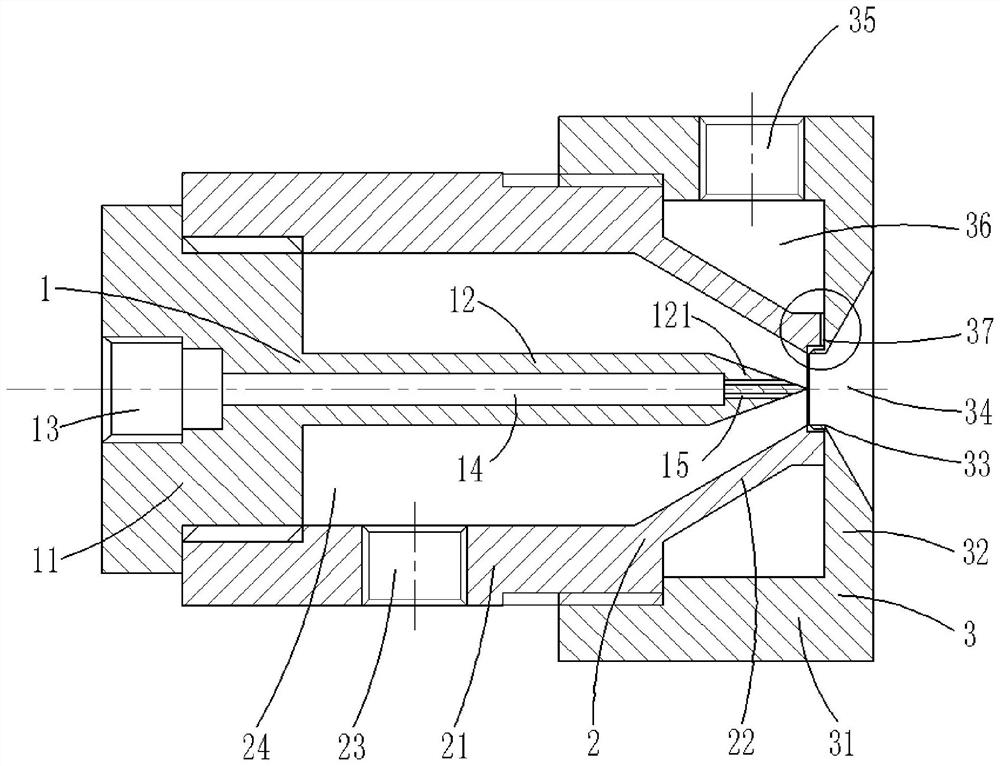

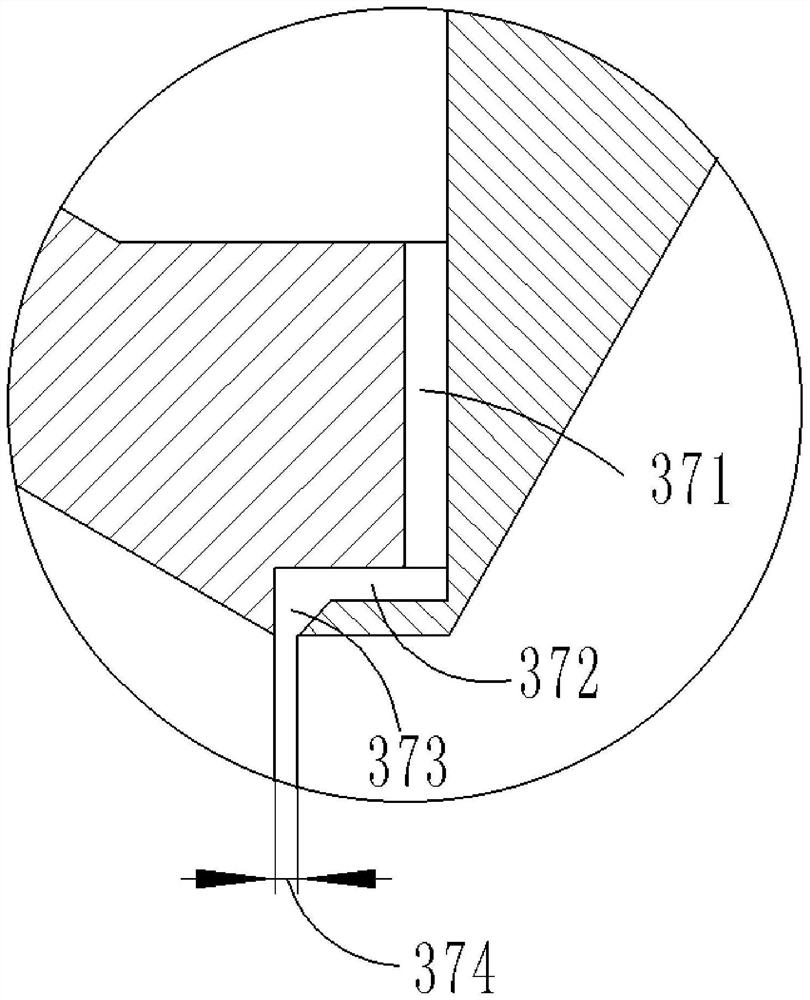

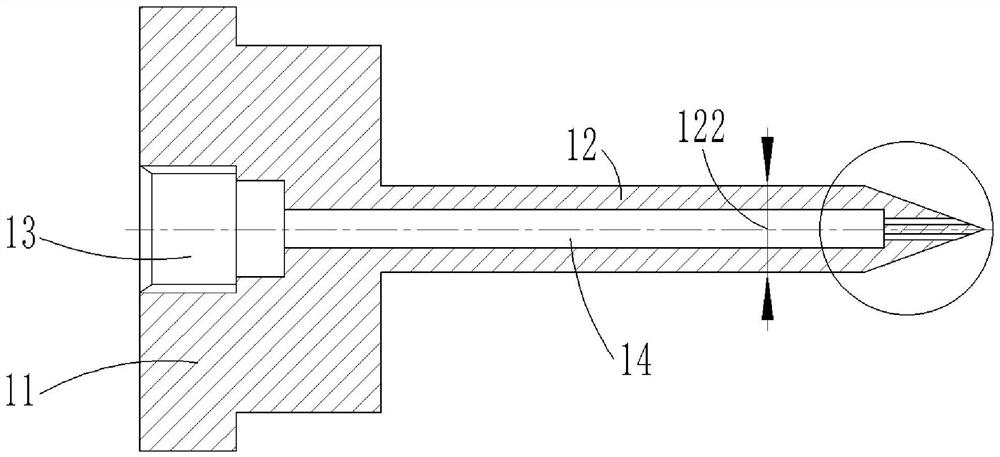

[0052] As shown in the accompanying drawings, an embodiment of the gas-assisted atomizing nozzle of the present invention includes a rear cover body 1, a middle sleeve 2 and a front sleeve 3, and the rear cover body 1 includes a nozzle rear cover 11 and a central liquid pipe 12. The middle sleeve 2 includes a cylindrical section 21 and a cone section 22, and the front sleeve 3 includes a coupling sleeve 31 and a cover plate 32. The nozzle rear cover 11 has a central liquid inlet 13 inside, and the central liquid pipe 12 has a central liquid cavity 14. The central liquid cavity 14 communicates with the external liquid inlet through the central liquid inlet 13. The central liquid pipe 12 It is a tubular structure, the central axis of the central liquid chamber 14 coincides with the central axis of the central liquid pipe 12, the front end 121 of the central liquid pipe is a conical closed structure, and the front end 121 of the central liquid pipe has several central liquid outle...

Embodiment 2

[0083] A nebulizer, the nebulizer includes the gas-assisted atomization nozzle described in Embodiment 1, and thus has the beneficial effects of Embodiment 1, which will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com