Pump and pumping system

一种泵壳、电子基板的技术,应用在泵和泵系统领域,能够解决不能满足信息设备小型化要求电子元器件高密度安装要求、增大电子基板面积、异常工作和故障等问题,达到实现小型化、提高安装效率、防止异常工作和故障的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Next, the best mode for carrying out the present invention will be described with reference to the drawings.

[0049] [Mechanical structure]

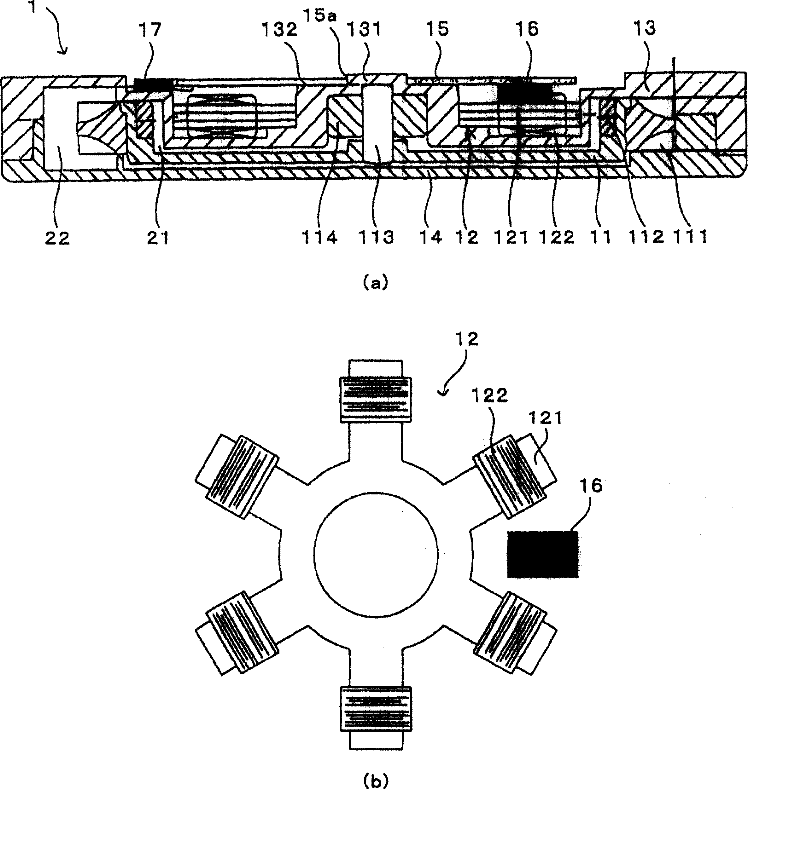

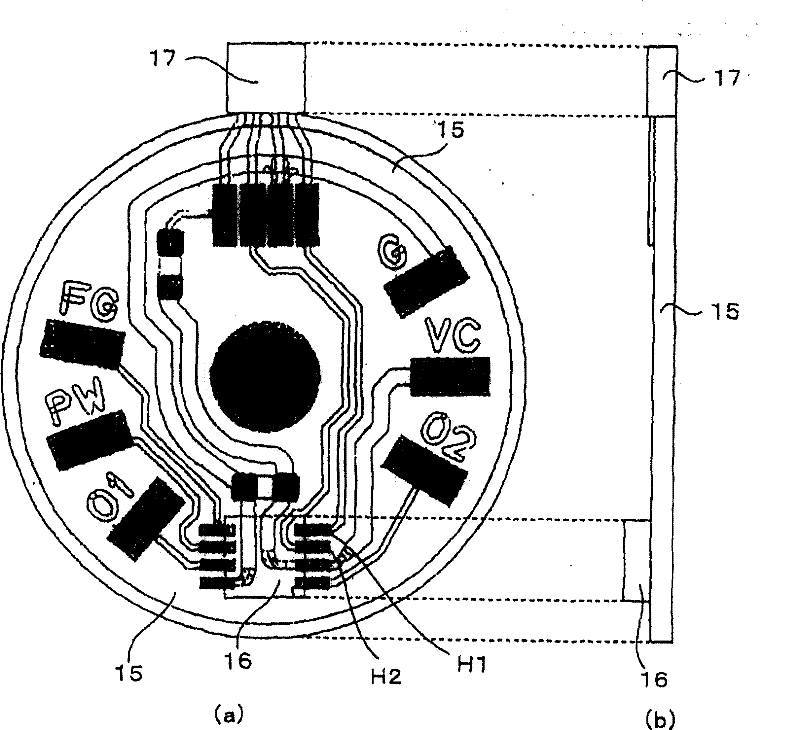

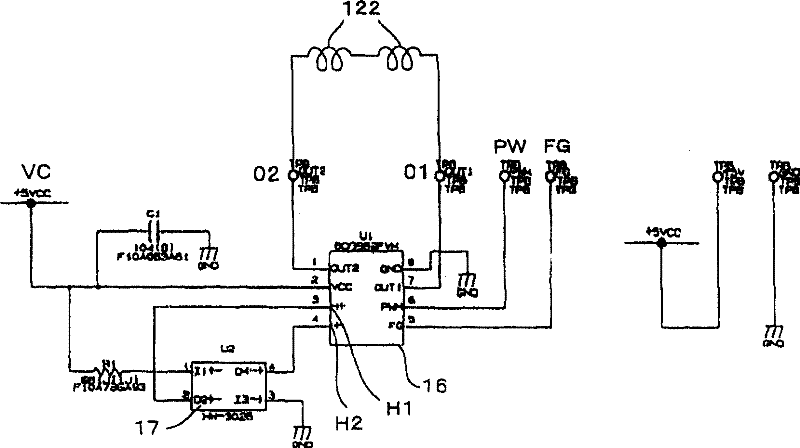

[0050] figure 1 It is a mechanical configuration diagram showing the pump 1 according to the embodiment of the present invention. in particular, figure 1 (a) shows a side sectional view of the pump 1, figure 1(b) is a schematic plan view showing the positional relationship between the stator 12 and the driver IC 16 . In addition, for the convenience of explanation, figure 1 (a) is upside down.

[0051] exist figure 1 In (a), the pump 1 according to this embodiment is mainly composed of an impeller 11 , a stator 12 , a pump casing 13 , and a bottom plate 14 .

[0052] A plurality of blades 111 are formed on the outer periphery of the impeller 11 , and the rotation of the impeller 11 induces eddy currents around the blades 111 . In addition, by performing waterproof processing on the surface of the blade 111, it is possible...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com