On-line thermal-insulating quenching apparatus and process

A technology of quenching device and heat preservation device, which is applied in the field of quenching device and quenching technology, can solve the problems of expensive equipment and complicated steps, and achieve the effects of reducing equipment investment, reducing energy consumption, and shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

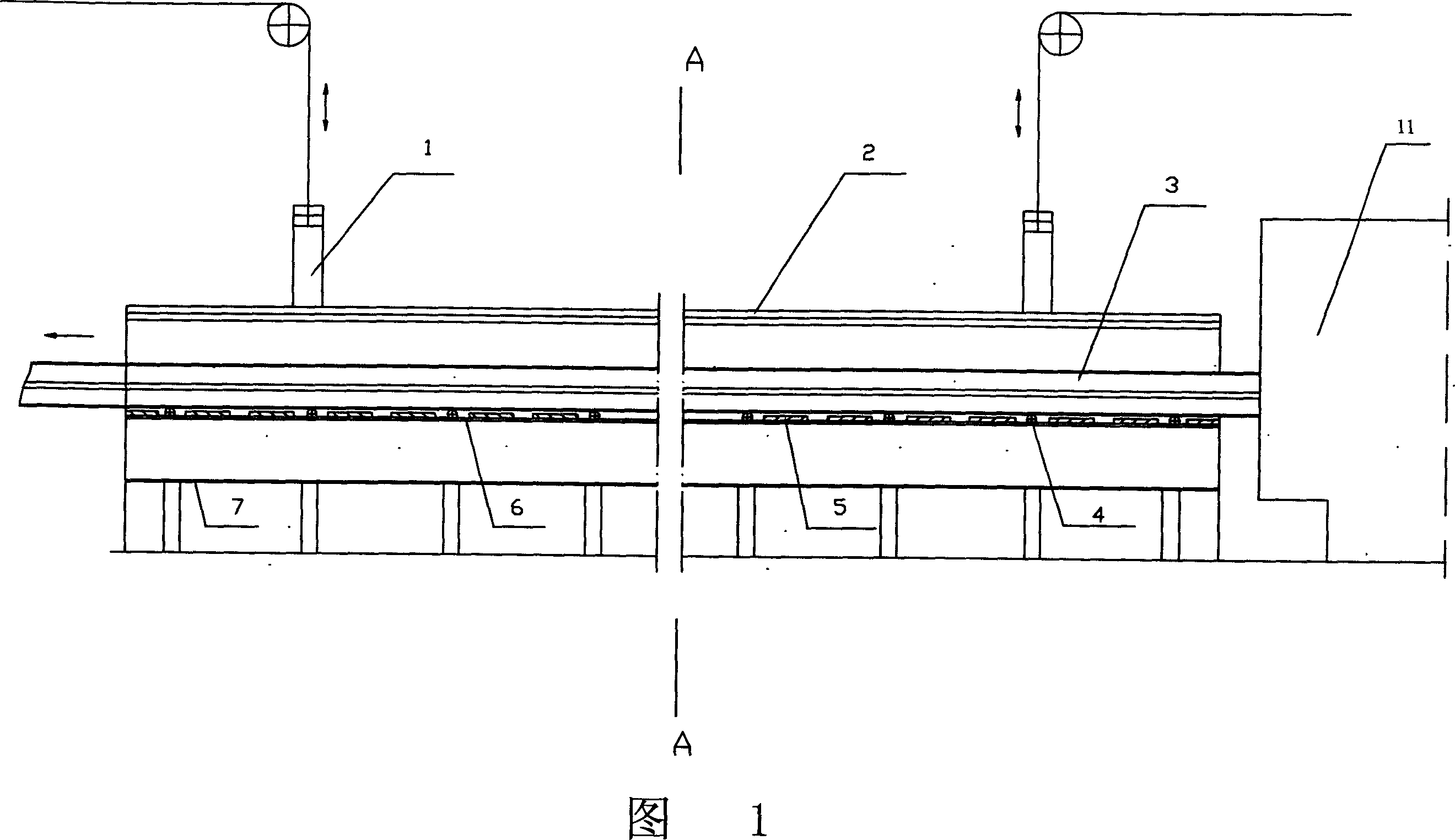

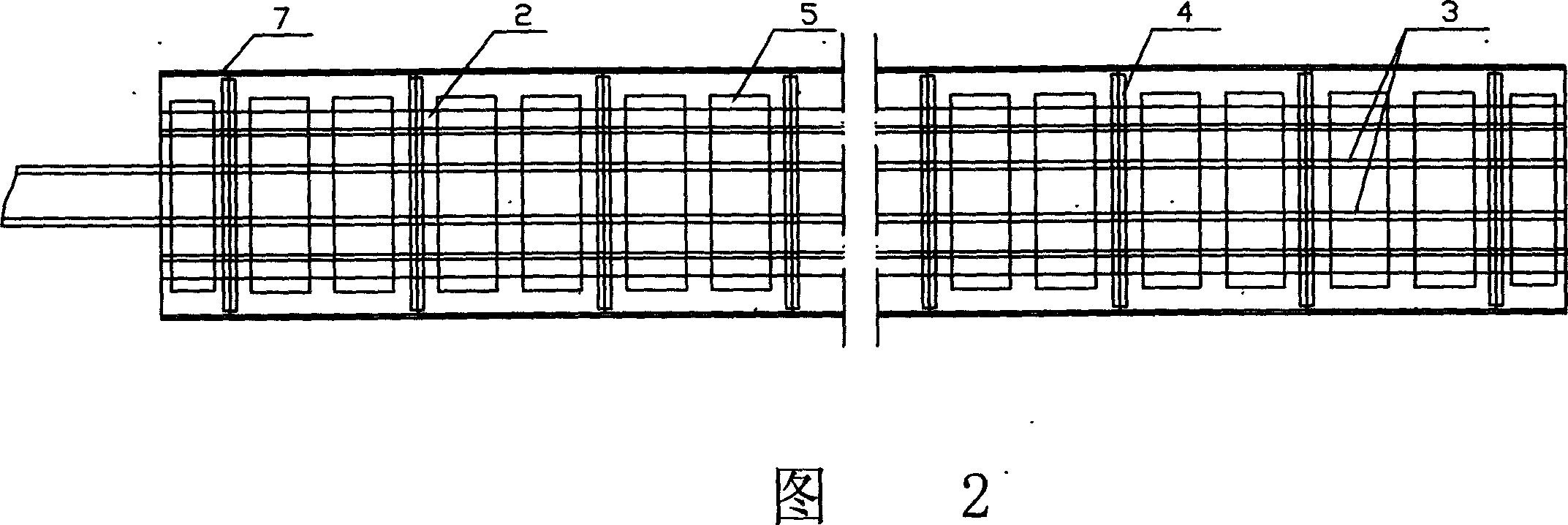

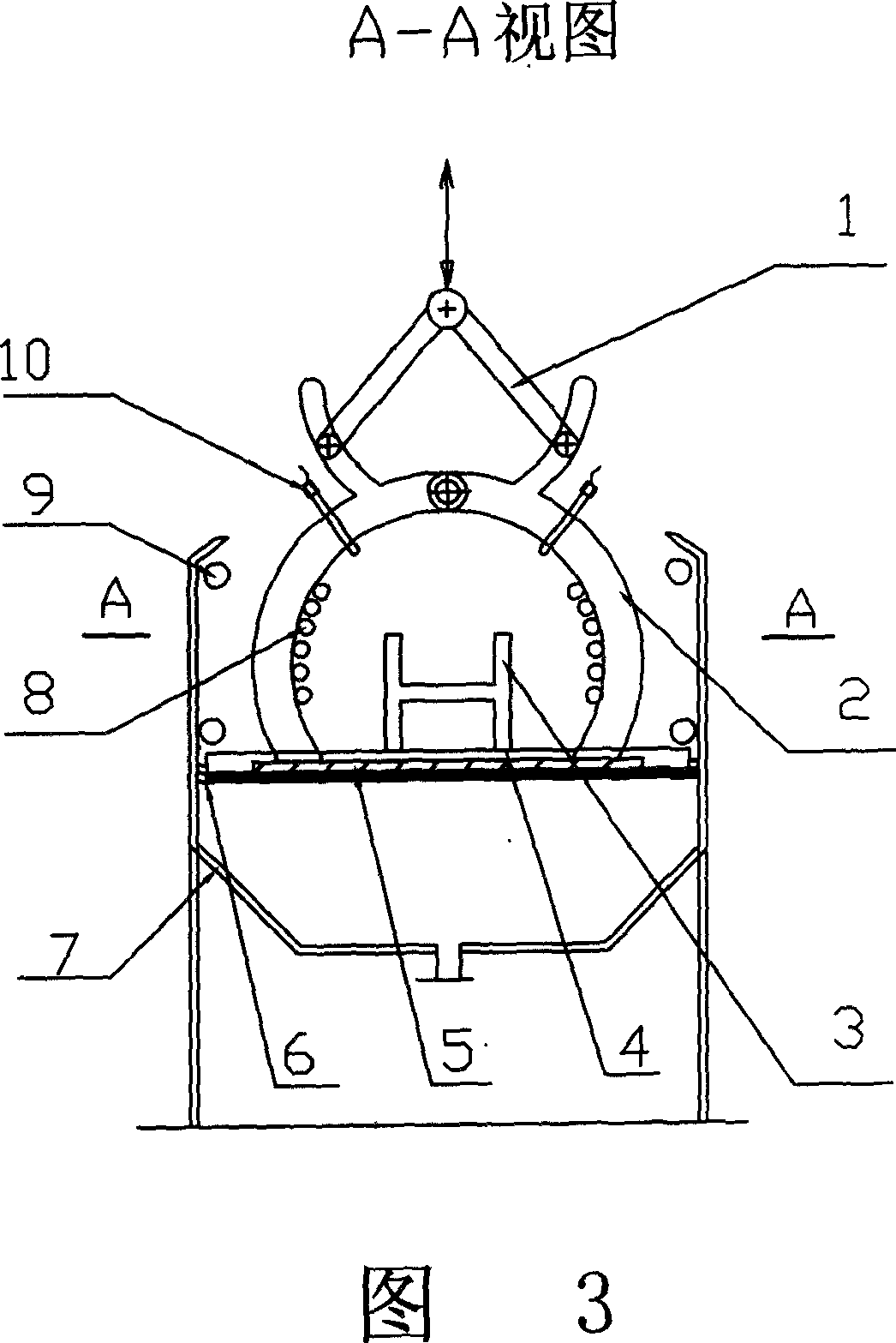

[0014] As shown in Figure 1, Figure 2, and Figure 3, the online heat preservation and quenching device consists of a support 1, a graphite plate 2, a cylinder 3, a water tank 4, a water spray pipe 5, a heating and heat preservation device 6, a temperature measuring element 7, and a lifting device 8 and other parts; the bracket 1 is located in the middle of the water tank 4 and is in the shape of a strip. The upper side of the bracket 1 is equipped with a plurality of rollers 3, and the rollers 3 are arranged at equal intervals. There are several graphite plates 2 between each two rollers 3. The bracket 1, the roller 3 and the graphite plate 2 form a slide-out platform structure, on which profile products can slide; the heating and heat preservation device 6 is in the shape of a pipe, buckled upside down on the slide-out platform, and the inner wall is equipped with an electric heating device 10; the water tank 4 is arranged on Sliding out of the platform periphery, water spray ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com