Production method for noble-metal-cluster-supporting catalyst

A precious metal and catalyst technology, applied in the field of catalyst production, can solve the problems of not being able to prepare a large number of clusters, difficult loading of precious metals, and inability to provide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] specific implementation plan

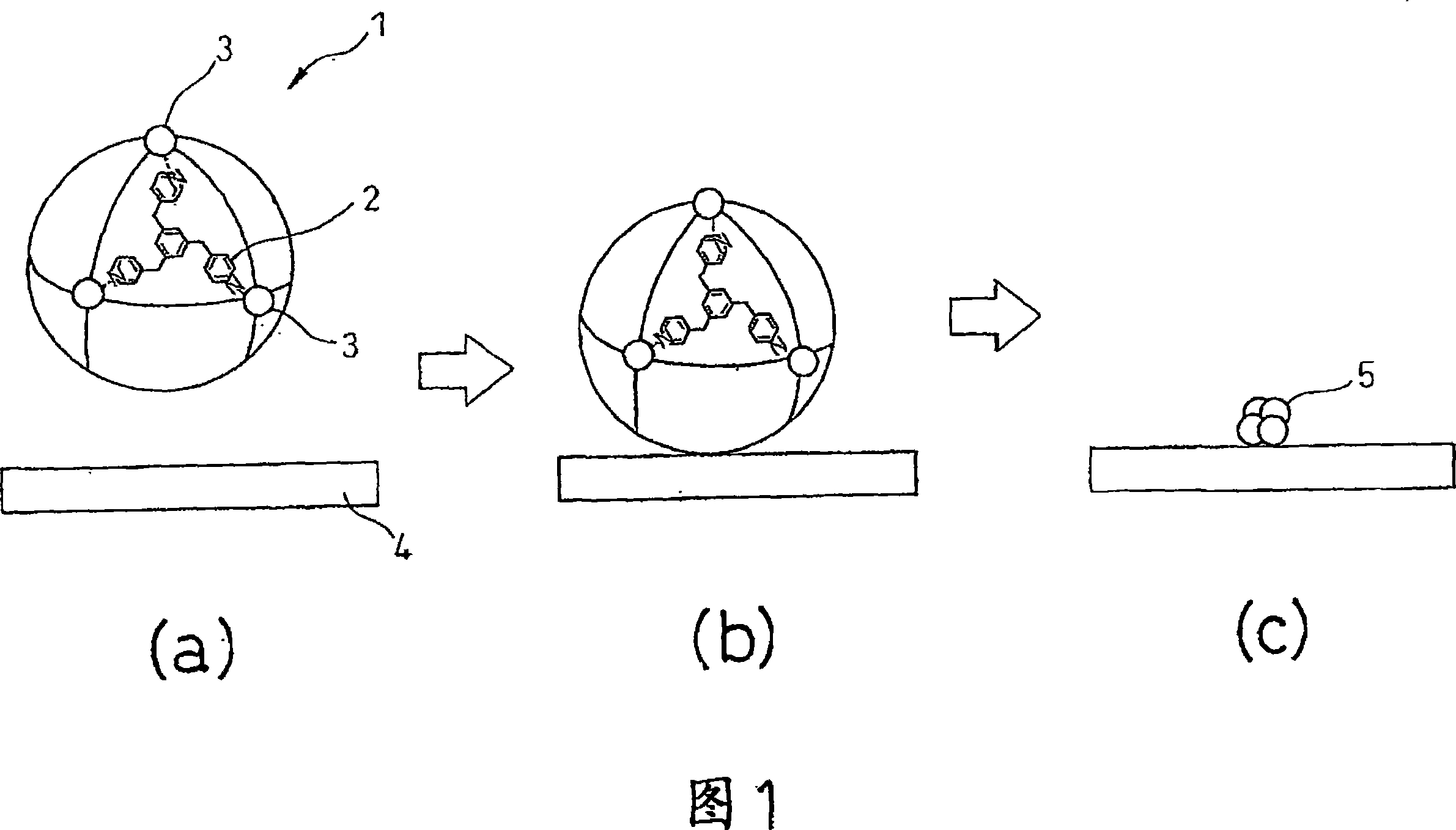

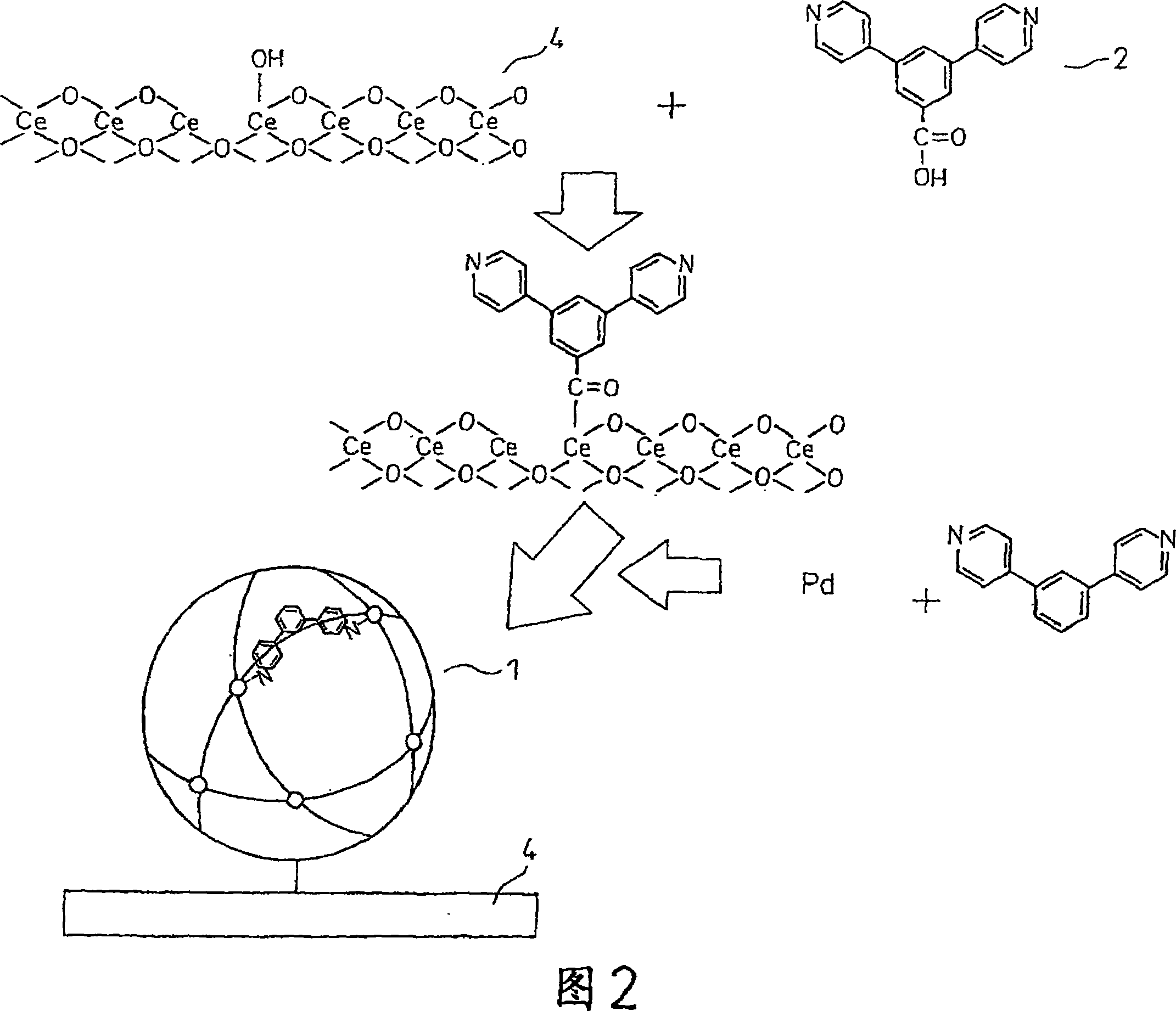

[0014] Figure 1 shows the method of the present invention. In the method of the present invention, a polynuclear complex 1 comprising a plurality of organic polydentate ligands 2 and a plurality of noble metal atoms 3 is firstly prepared. The multinuclear complex 1 has a closed capsule structure, and is prepared by reacting an organic multidentate ligand 2 and a noble metal atom 3 according to a common production method for complexes.

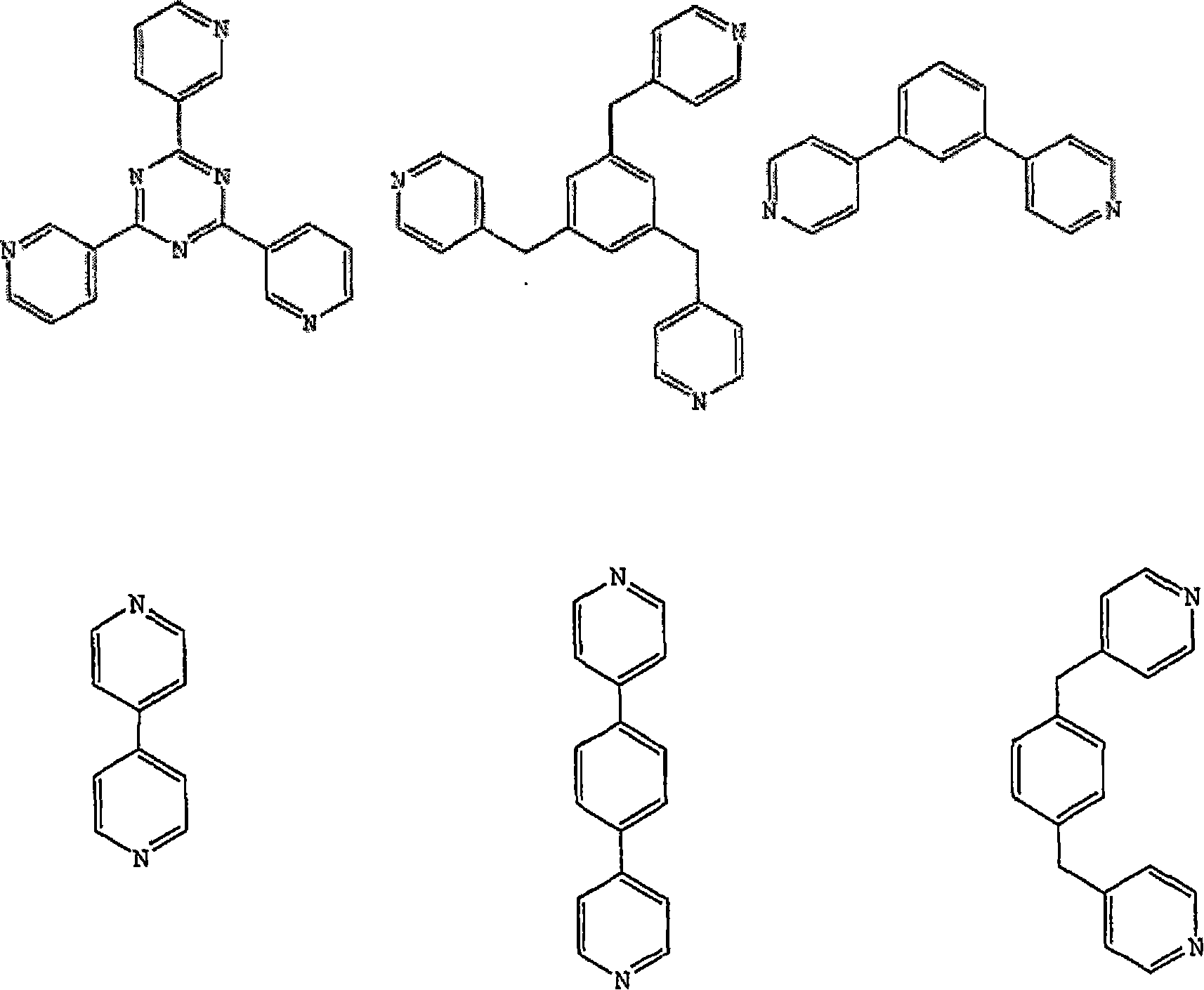

[0015] As the organic multidentate ligand 2, for example, organic compounds shown below can be used.

[0016]

[0017] As the noble metal atom 3, at least one selected from platinum, rhodium, palladium, gold, and iridium can be used.

[0018] Specifically, when using the compound shown below as the organic polydentate ligand 2,

[0019]

[0020] get with M 6 L 8 The composed capsule-like molecule acts as a polynuclear complex 1, as follows:

[0021]

[0022] Moreover, when using the compound ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com