Fume extractor of laser cutting machine tool

A technology of laser cutting machine and smoke exhaust device, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of incomplete smoke exhaust, pollution of indoor environment, smoke floating, etc., and achieve the effect of rapid smoke exhaust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

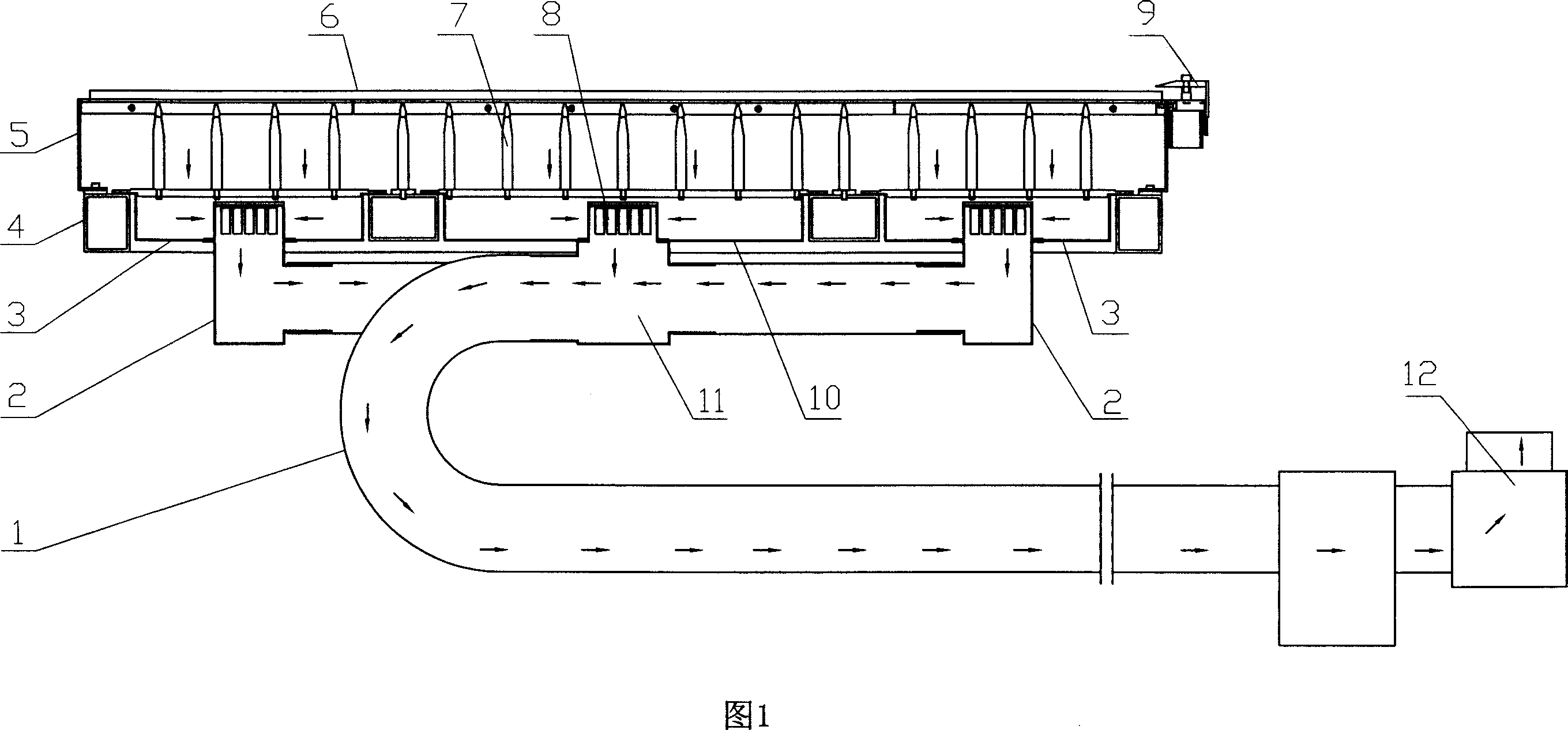

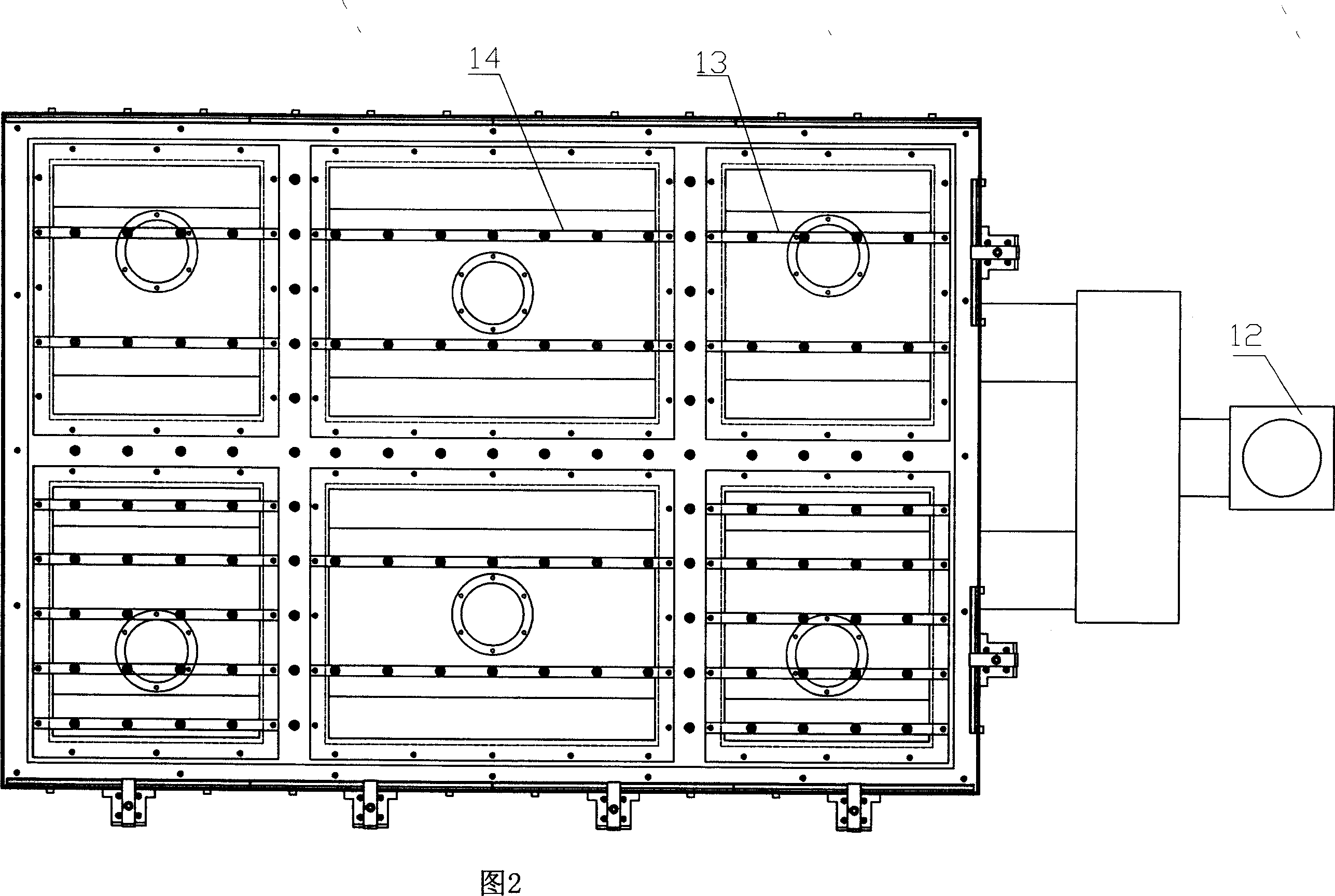

[0019] First please refer to Fig. 1 and Fig. 2, the laser cutting machine adopting the smoke exhaust device of the present invention is installed with the front view and the top view of the workpiece 6, which includes the workpiece table 4, the work surface frame 5 installed on the workbench 4, and the installation For the thimble 7, short support bar 13 and long support bar 14 on the workbench 4, the work table frame 5 is provided with clamps 9, when the workpiece 6 is installed on the work table frame 5, the thimble 7, the short support bar 13 and the long support bar 14 The support bar 14 plays a supporting role, and the clamp 9 plays a positioning and clamping role.

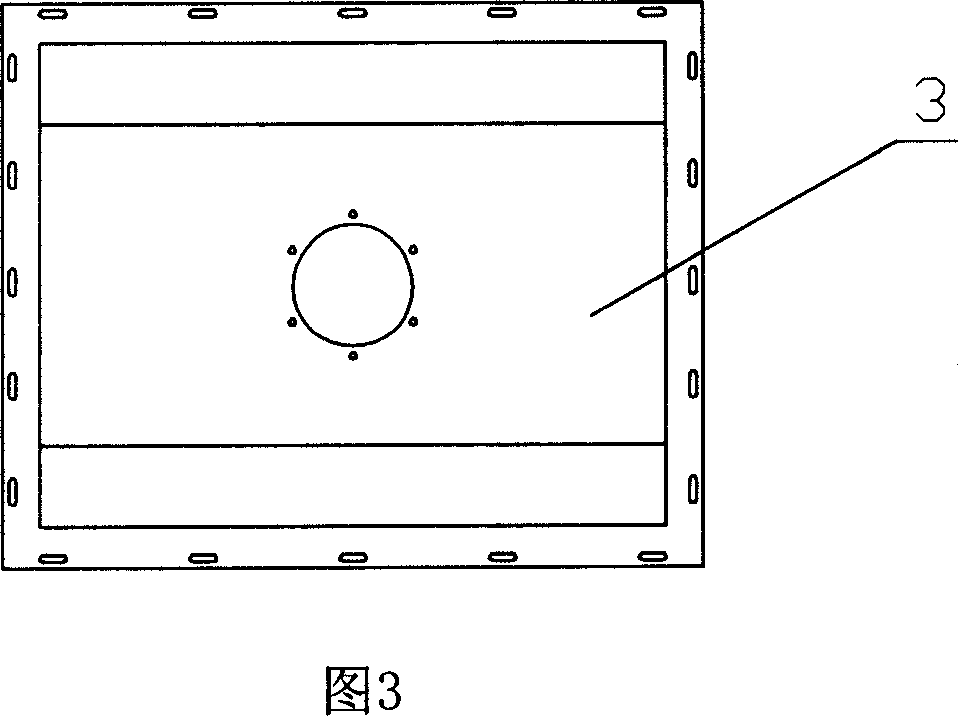

[0020] The present invention also is equipped with blanking groove 3,10 on workbench 4. The structure of the blanking chute 3 is shown in its top view and right view as shown in Figure 3 and Figure 4, and the structure of the blanking chute 10 is shown in its top view and right view as shown in Figure 5 and F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com