Automobile door structure

A technology for automobile doors and doors, which is applied to door leaves, windows/doors, building components, etc. It can solve problems such as difficulty in demoulding and deterioration of the formability of the load-bearing plate, and achieve the effect of improving the formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

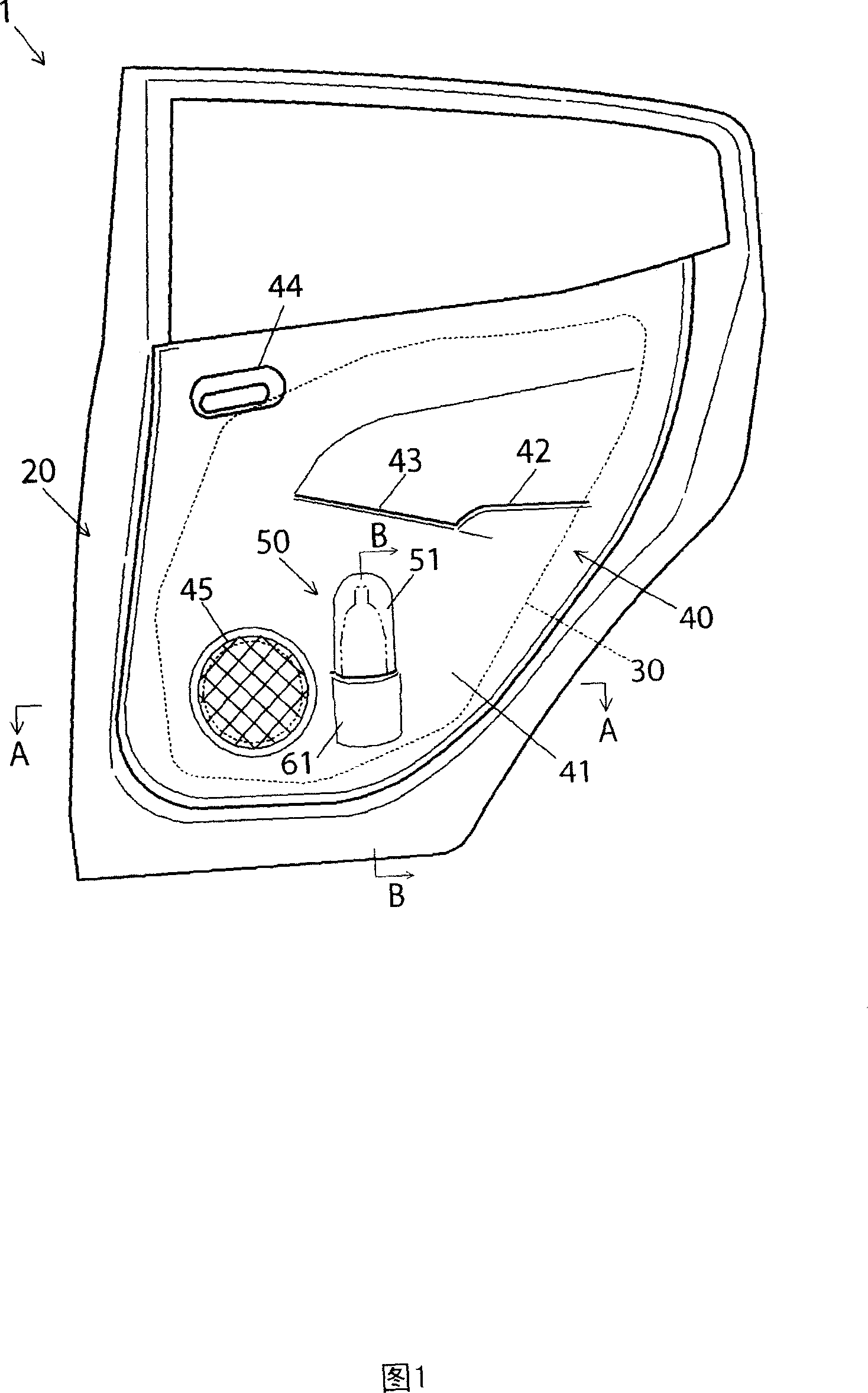

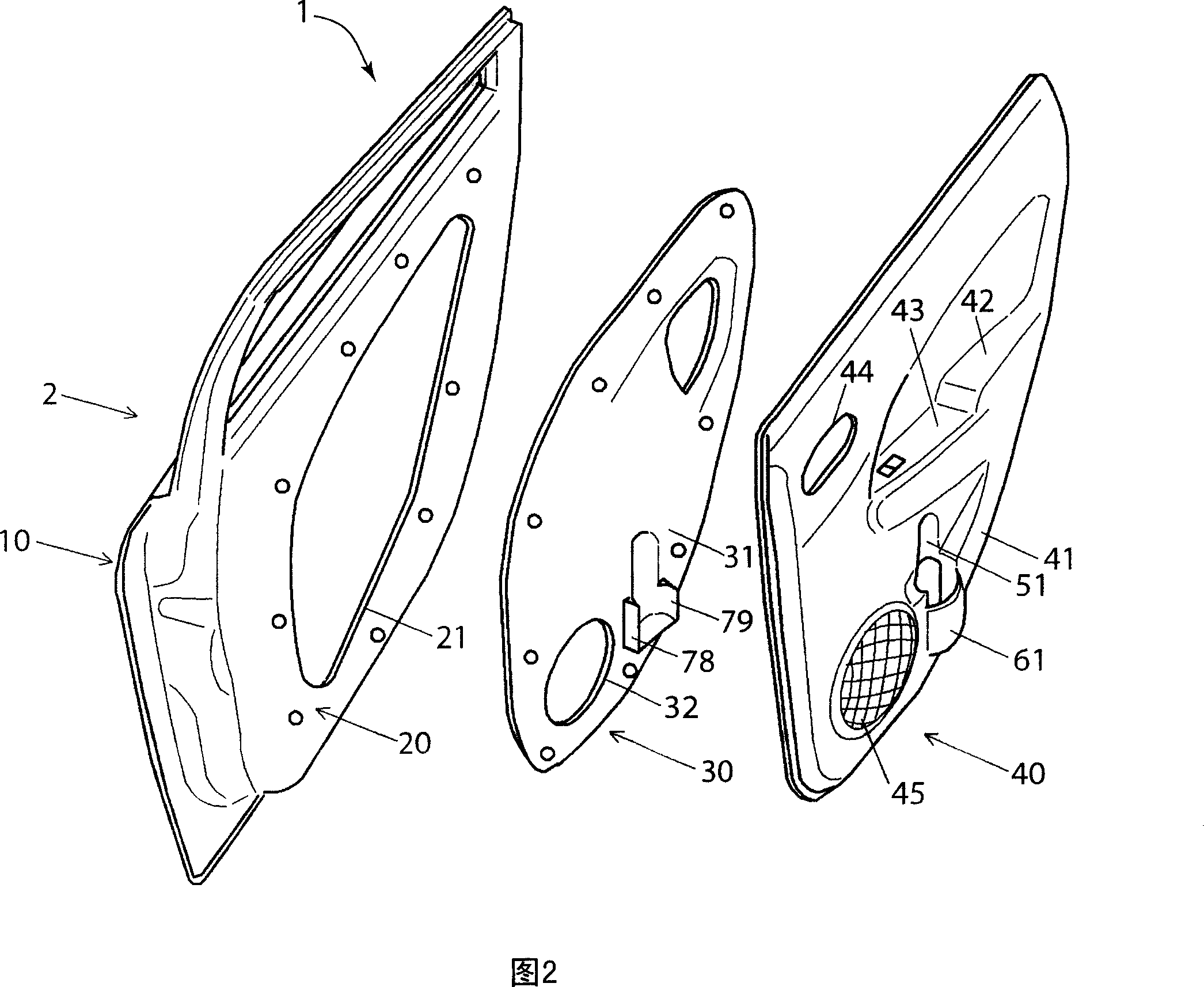

[0033] Next, an automobile door structure according to an embodiment of the present invention will be described.

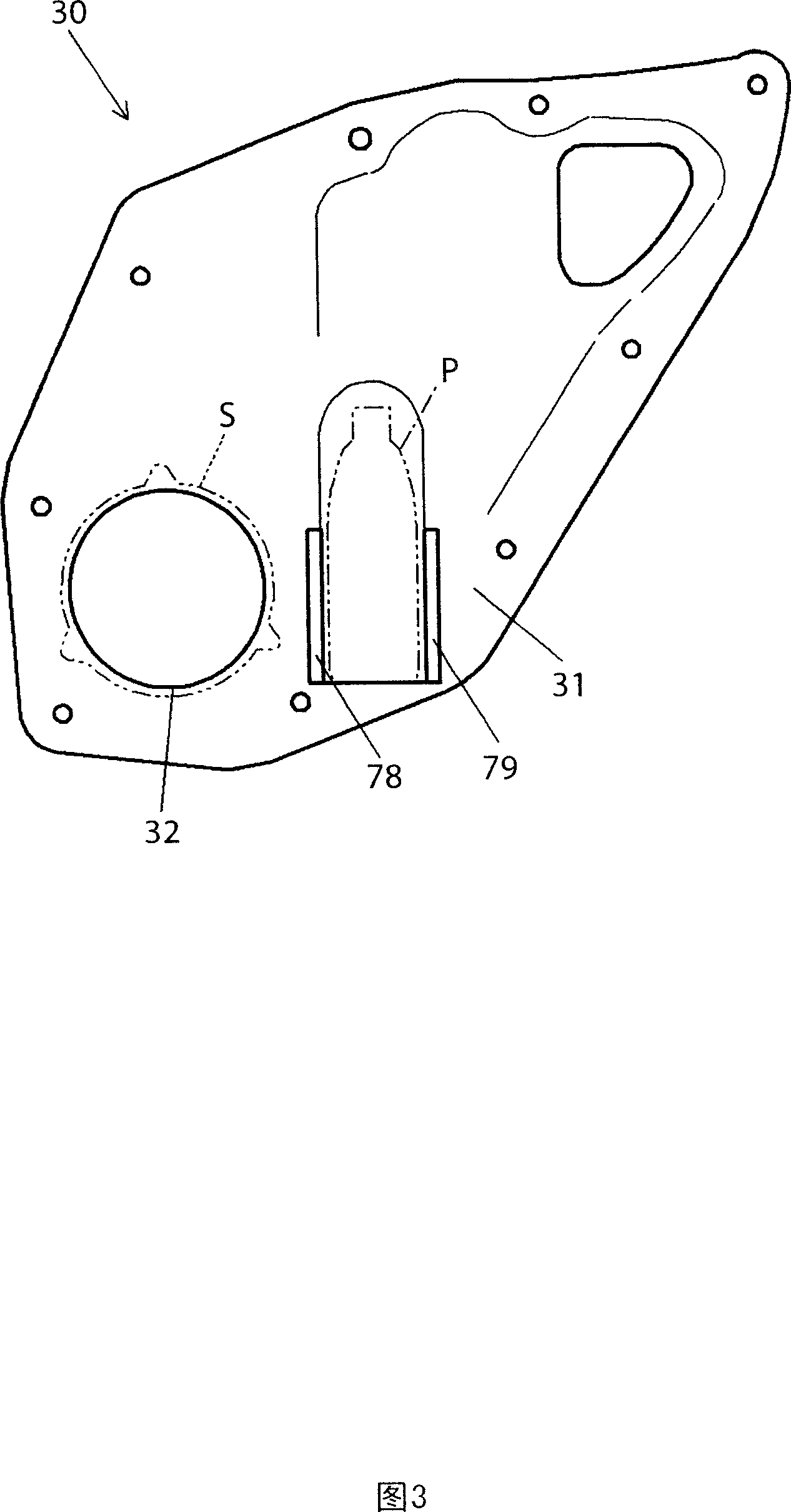

[0034]The automobile door structure involved in the present invention can be applied to the right rear side door 1 shown in FIG. 1 . As shown in FIG. 1 and FIG. 2 , the vehicle door 1 includes a vehicle door main body 2 , a bearing plate 30 and a vehicle door trim 40 . The door main body portion 2 is formed into a hollow body by including an outer panel 10 constituting an outer appearance surface of the vehicle door 1 and an inner panel 20 provided on the interior side of the outer panel 10 . In addition, the receiving plate 30 blocks the opening 21 located substantially in the center of the inner panel 20 . Furthermore, the above-mentioned door trim 40 is provided on the vehicle inner side of the carrier plate 30 .

[0035] The above-mentioned carrier plate 30 is formed by injection molding using a glass fiber-containing FRP resin material using a mold. The ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com