Mechanical plug-removal oil extraction device

A technology of mechanical plugging removal and oil extractor, which is applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc., and can solve problems such as no function of plugging removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

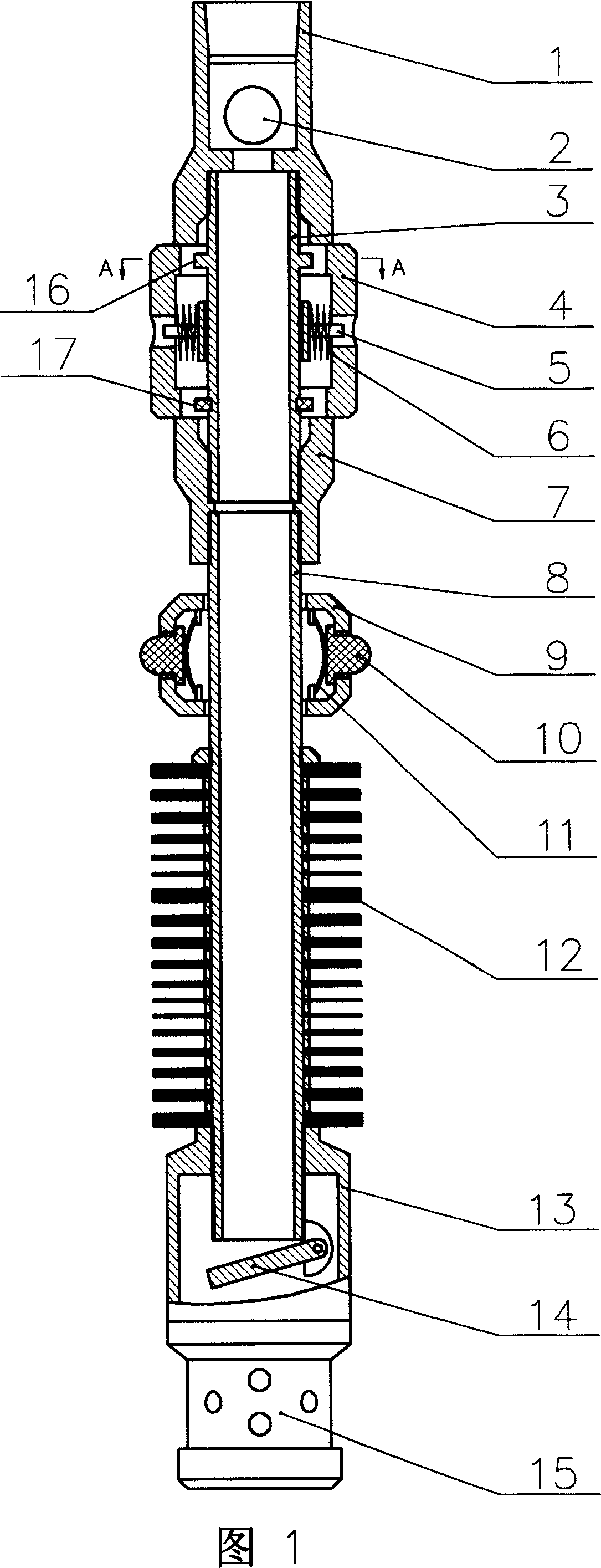

[0029] In Fig. 1, the upper end of the upper joint 1 is a female thread, which is connected with the lower oil pipe of the oil pump in the oil well, and the lower end is also a female thread, which is connected with the upper center pipe 3, and a forward check valve 2 is installed in the middle cavity; The middle and upper part of the center pipe 3 is provided with a boss 16, the middle part is set with the reducing piston assembly 4, the middle and lower part is equipped with a circlip 17, and the lower end is connected with the lower center pipe 8 through the lower joint 7; the inner cavity of the reducing piston assembly 4 is installed There are springs 6 and spring brackets 5; the upper part of the lower center tube 8 is fitted with a hollow vibrating ring assembly 9, the middle part is equipped with a vibrating plate group 12, the lower part is connected to the screen pipe 15 through the outer cylinder 13, and the reverse check valve 14 is installed at the bottom; the hollo...

Embodiment 2

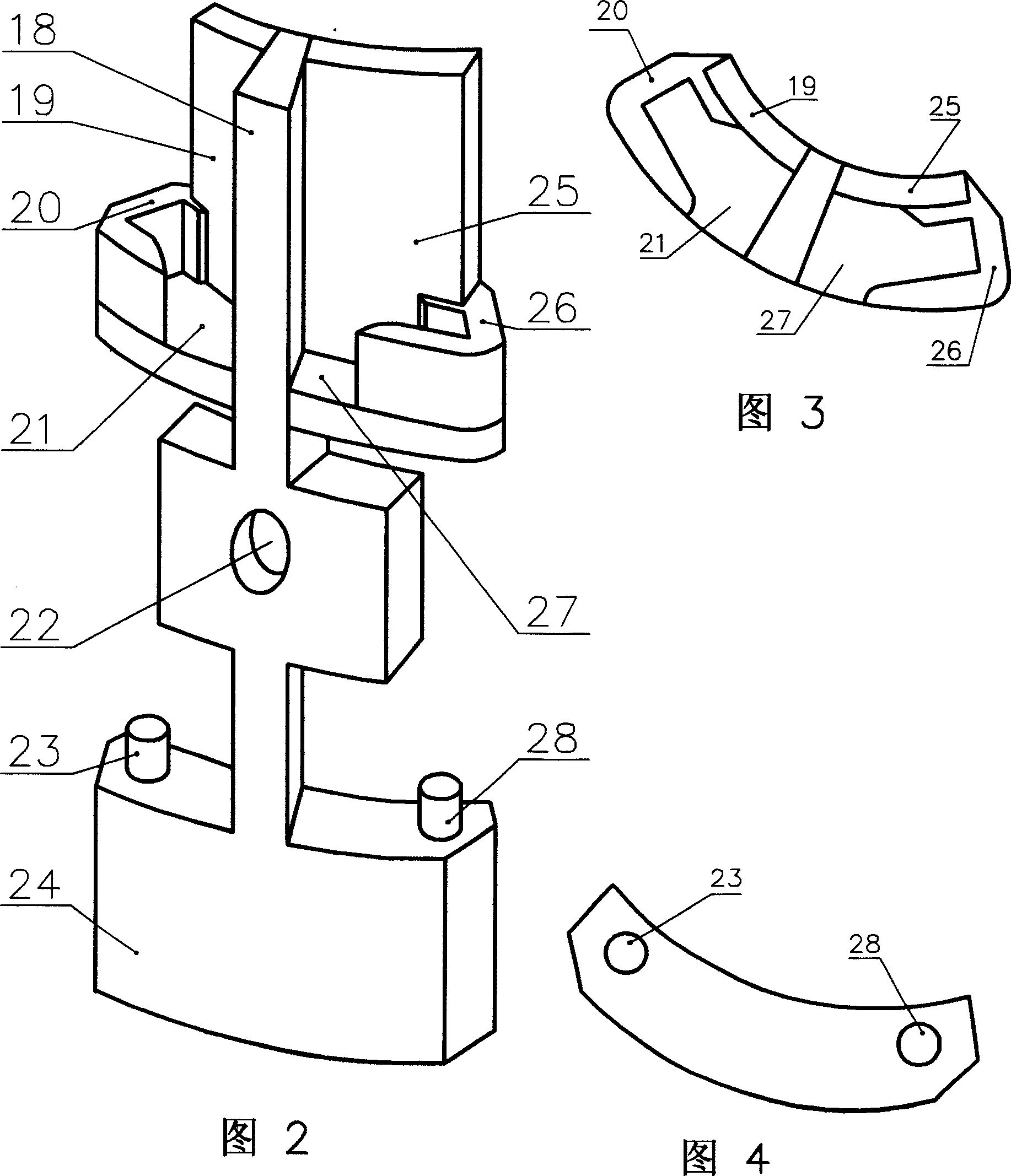

[0039] In Fig. 11, the upper and lower ends and the left and right sides of a single arc-shaped piston block are all equipped with a hook-shaped slideway stop baffle plate 20 and a pin shaft slideway 21.

[0040] In Fig. 12, pin shafts 23 are installed at the upper and lower ends and the left and right sides of a single arc-shaped piston block.

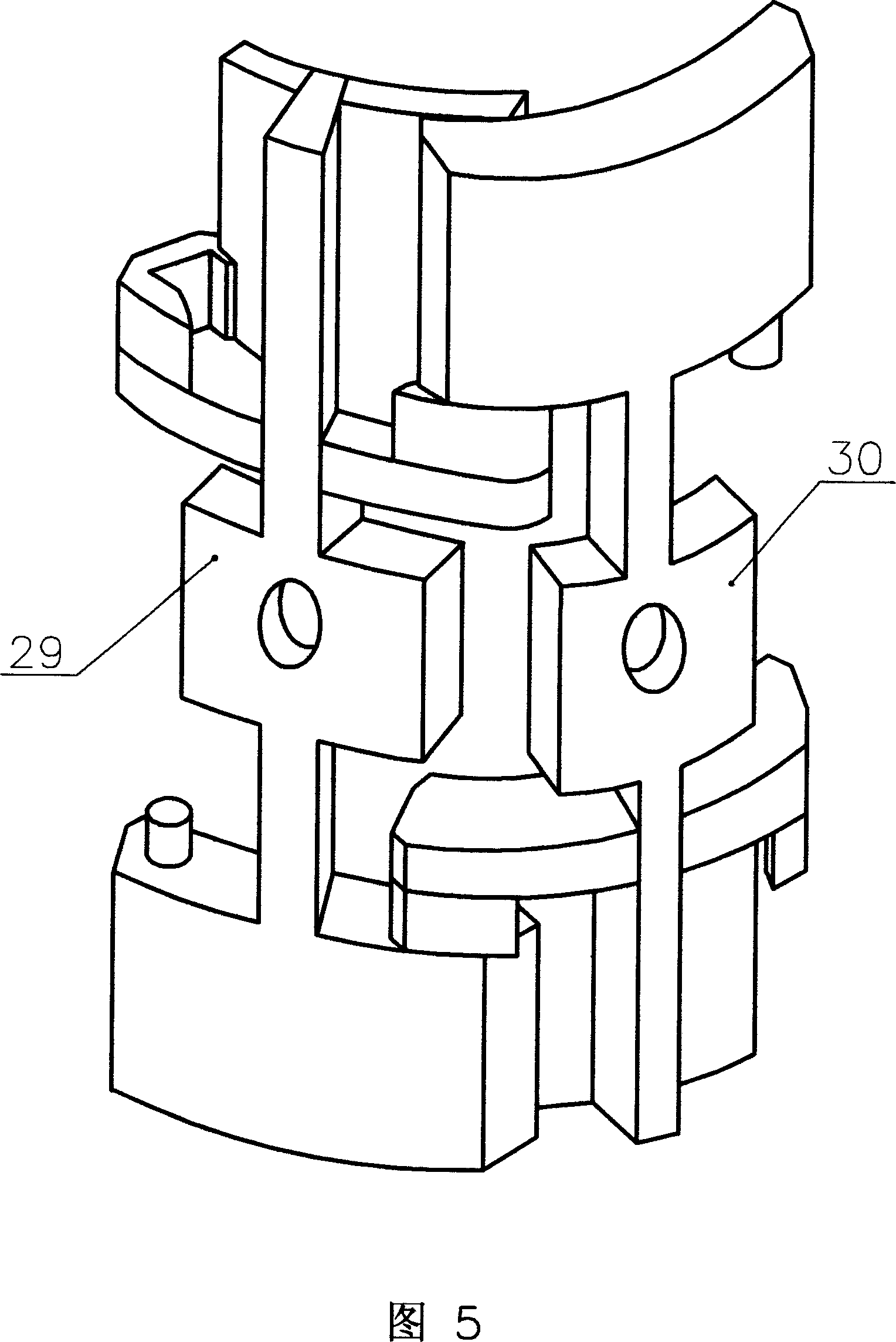

[0041] In Fig. 13, the left side is a single arc-shaped piston block 32 with a hook-shaped slideway stop baffle plate and a pin shaft slideway installed at the upper and lower ends and the left and right sides, and the right side is a single arc-shaped piston block 32 with the upper and lower ends and the left and right sides. A single arc-shaped piston block 33 of pin shaft is installed; as can be seen from Figure 13, a single arc-shaped piston block with hook-shaped slideway stop baffle and pin shaft slideway is installed at the upper and lower ends and the left and right sides 32 is snapped together with a single arc-shaped piston ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com