Rock joint shear-seepage coupling experiment box

A technology of rock joints and test boxes, applied in the field of test boxes, can solve the problems of too small osmotic water pressure value and slow development of testing machines, and achieve the effect of real data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

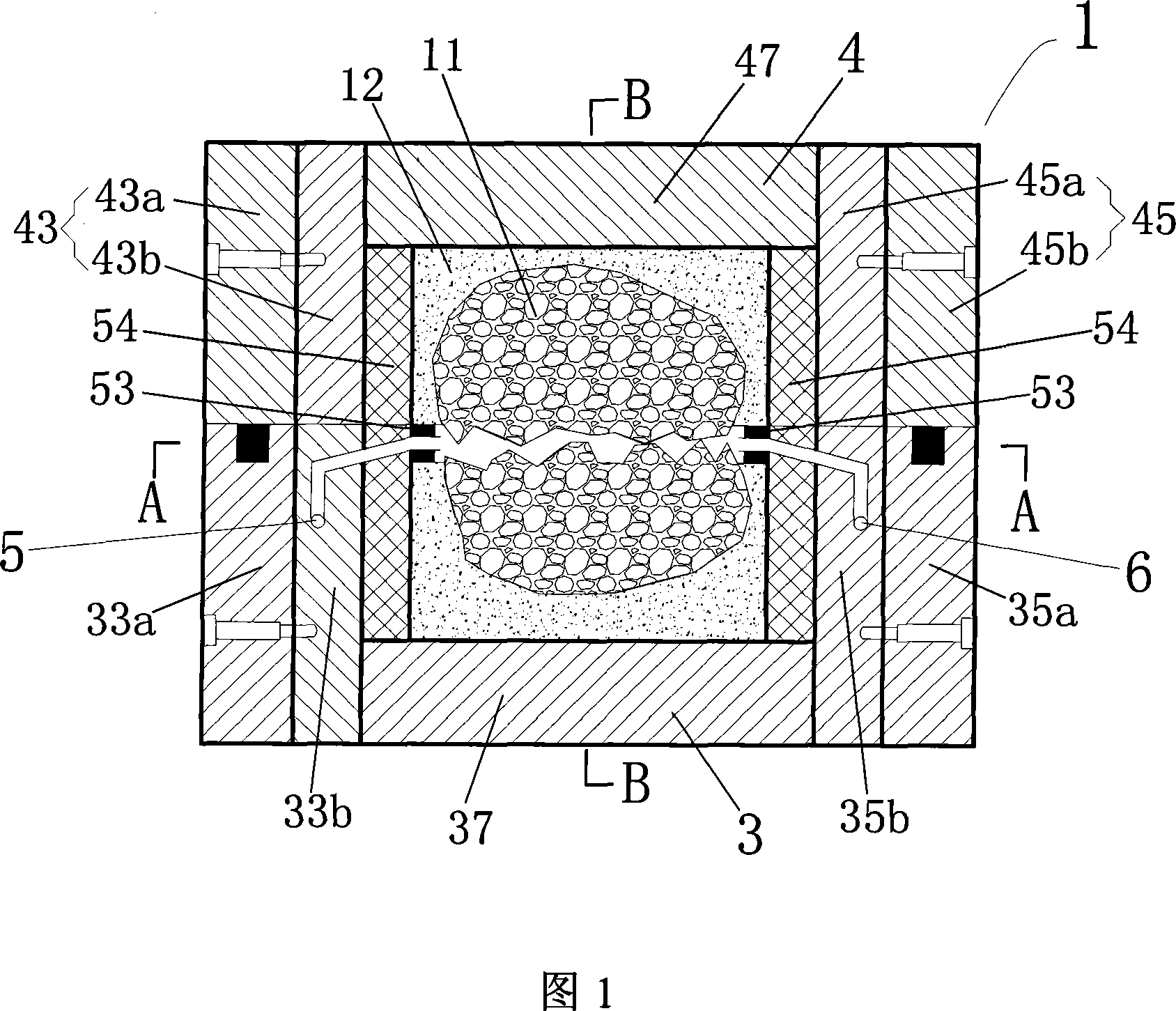

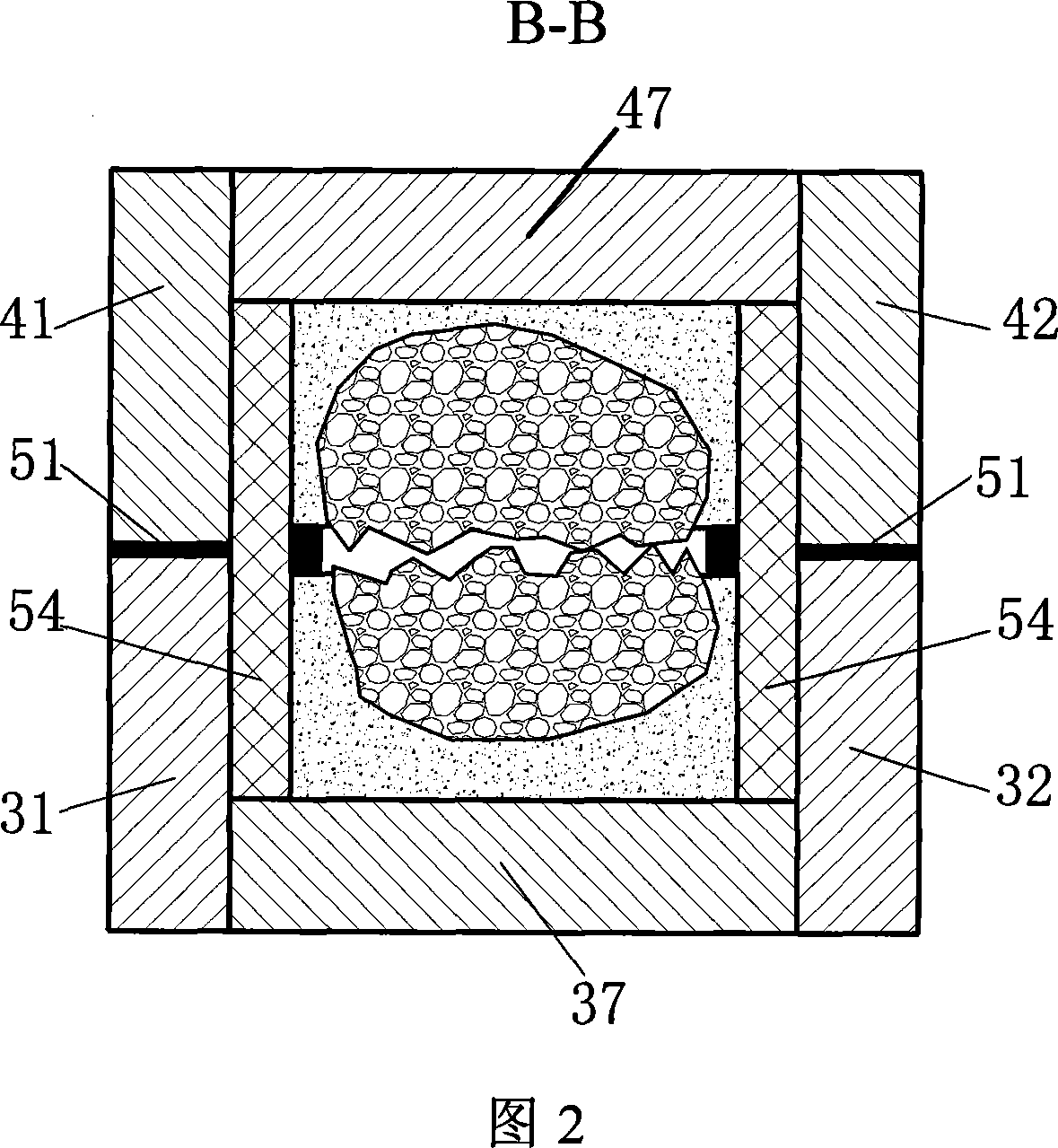

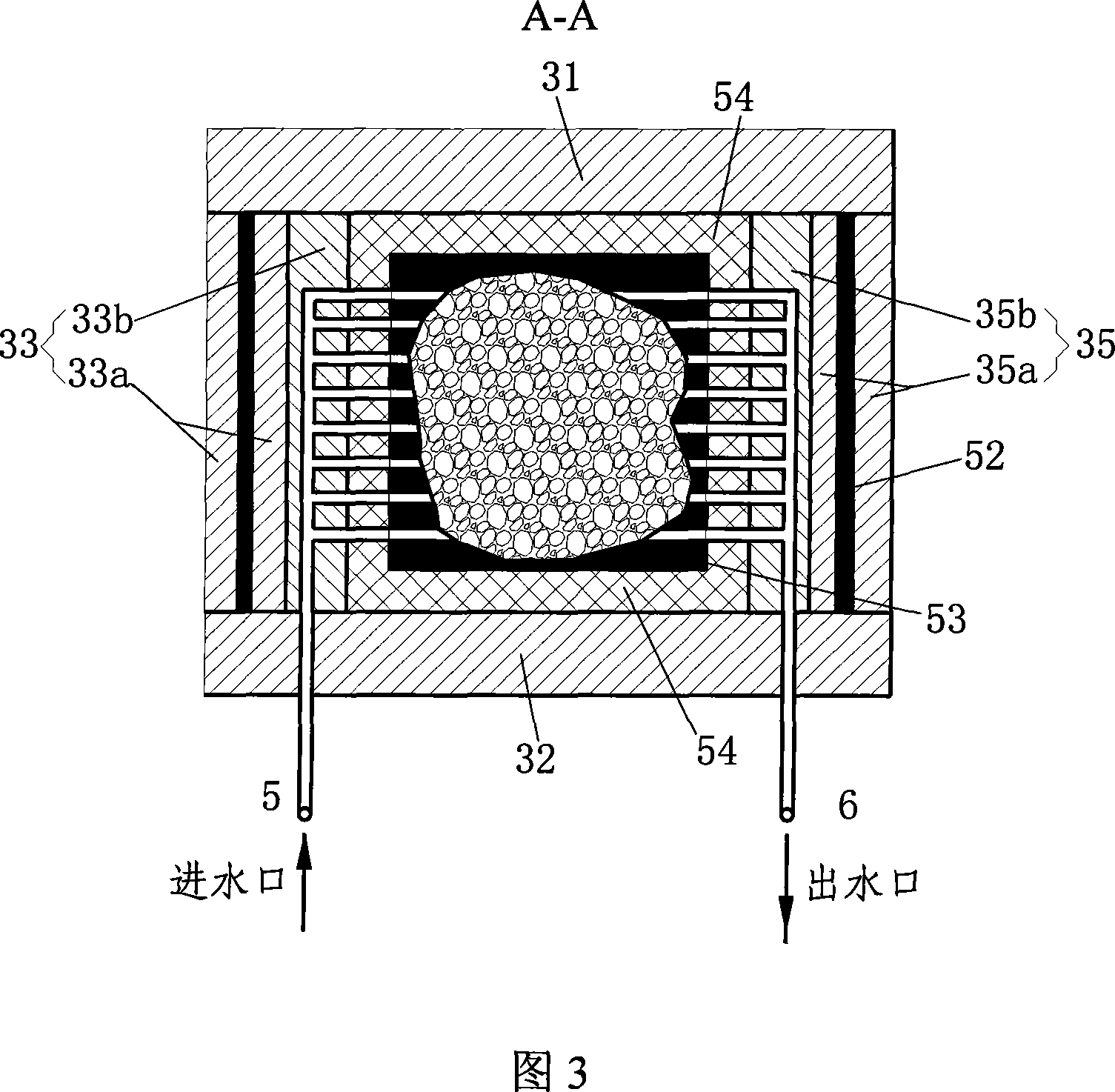

[0019] The inventive rock joint shear-seepage coupling test box will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0020] As shown in Figures 1 to 3, the rock joint shear-seepage coupling test box, the box body 1 includes a lower box 3, an upper box 4, a water inlet pipe 5, and a water outlet pipe 6, forming a rock joint shear-seepage coupling test The box body wall panels of box 1 are all made of steel plates, and can also be made of other metals or alloys with high compressive strength and good water corrosion resistance.

[0021] Lower box 3 is made up of a front wall plate 31, a rear wall plate 32, a left wall plate 33, a right wall plate 35 and a lower wall plate 37; the front wall plate 31 and the rear wall plate 32 are the same size and thickness. Two steel plates are symmetrically arranged; the left wall plate 33 and the right wall plate 35 are formed by two steel plates with the same size and different thicknesses...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com