Automatic zero correction method for bio-safety cabinet wind speed sensing device

A wind speed sensor and sensor technology, applied in the testing/calibration of speed/acceleration/shock measuring equipment, instruments, speed/acceleration/shock measurement, etc., to achieve the effect of preventing unnecessary danger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

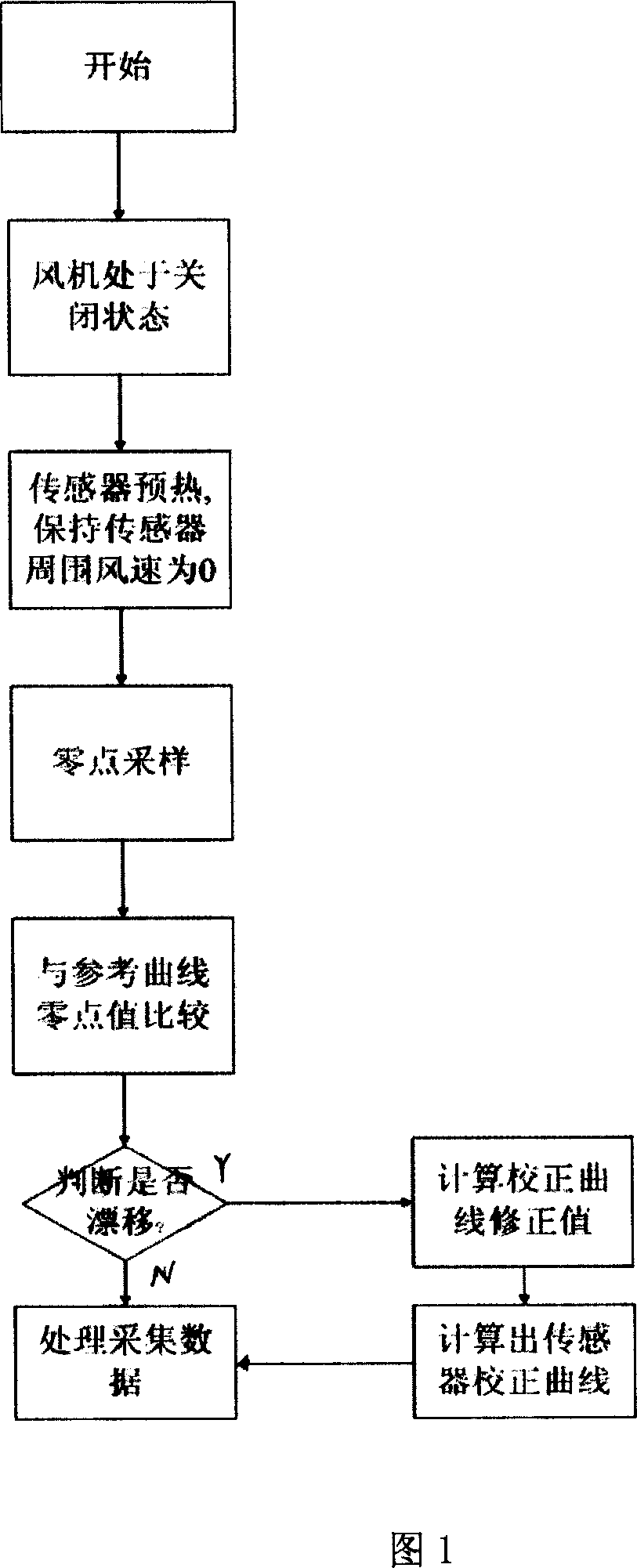

[0020] As shown in FIG. 1 , it is a program flow chart of an automatic zero point calibration method for a wind speed sensor of a biological safety cabinet.

[0021] For the convenience of description, the following nouns are introduced first:

[0022] Sensor reference curve: the collection point curve calibrated by the sensor during initial use

[0023] Sensor drift curve: the collection point curve of the sensor when it drifts

[0024] Sensor calibration curve: the corrected sensor collection point curve (should be a curve that coincides with the reference curve)

[0025] Calibration curve correction value: the difference between the zero point value of the reference curve of the sensor and the zero point value of the drift curve of the sensor.

[0026] Zero wind speed value: its value is 0, after starting up, the wind speed value when the fan is not turned on.

[0027] High point wind speed value: the wind speed value of the set point to ensure the user can use it safely...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com