High-current low-voltage DC electromotor control switch

A low-voltage DC, motor control technology, applied in the electrical field, can solve the problems of shortened life, accelerated switch aging, increased resistance, etc., and achieves the effect of good insulation performance and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

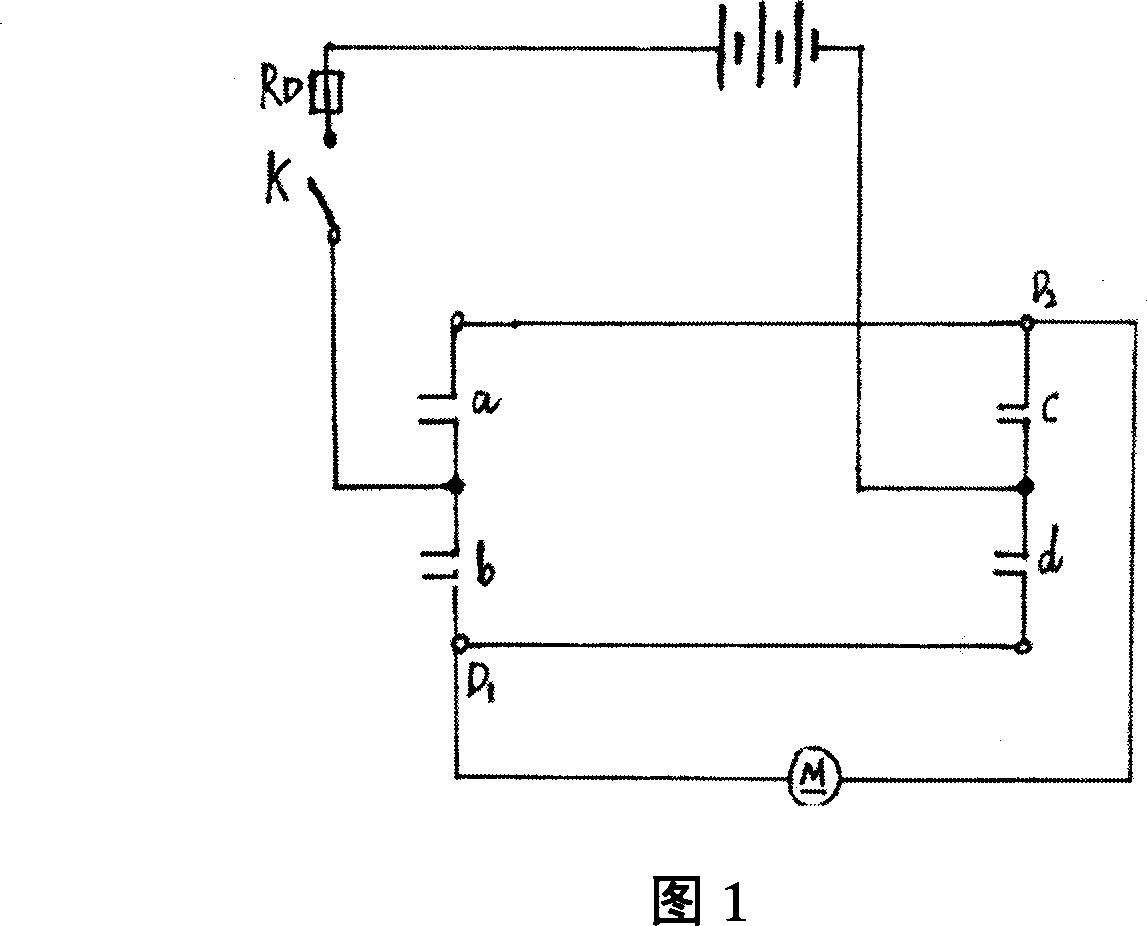

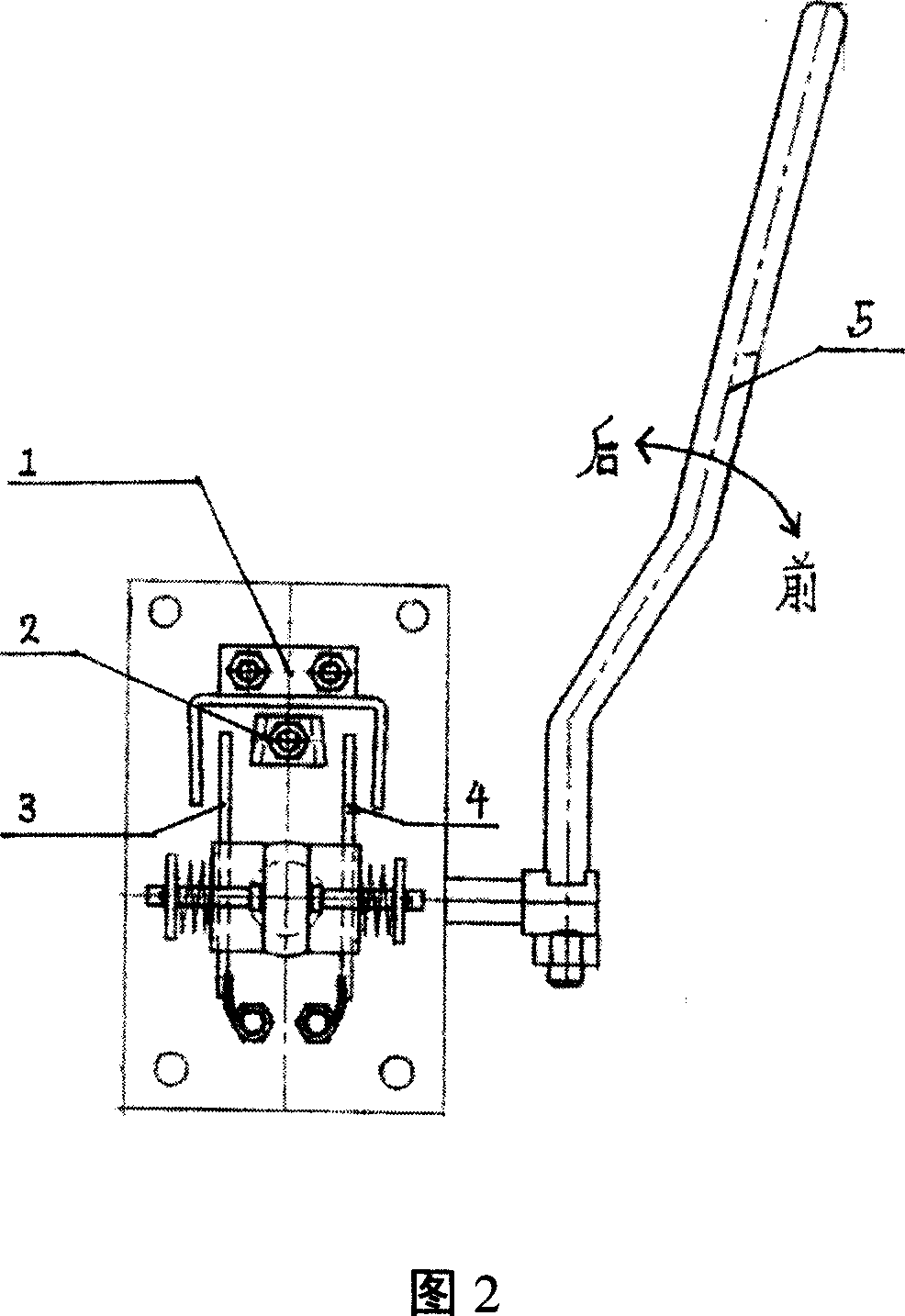

[0012] A high-current low-voltage DC motor control reverse switch, comprising a blocking rod 5 and two sets of mutually corresponding static contact pieces 1, 2 and movable contact pieces 3, 4, and also includes four terminals: L1 and L2 are respectively connected to DC The positive and negative poles of the power supply, D1 and D2 are respectively connected to the two ends of the motor electrodes; among them, the blocking rod 5 has three positions: when the blocking rod 5 is in the stop position, the two sets of moving contact pieces 3 and 4 are not connected to the static contact pieces 1 and 2. Contact, the circuit is blocked, and the motor does not turn; when the lever 5 is pulled to the forward position, the a and d contacts are closed, and the motor is powered on and runs in the forward direction; when the motor needs to run in the reverse direction, the lever 5 can be pulled To the reverse position, at this time, the b and c contact pieces are connected, and the motor is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com