Down-transmission type centrifugal extractor for the chemical industry operation

An extractor and transmission type technology, applied in the field of lower transmission type centrifugal extractor, can solve the problems of loss of precision of centrifugal drum, troublesome replacement method, unusable equipment, etc., so as to achieve the problem of not destroying processing precision, prolonging service life and running smoothly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

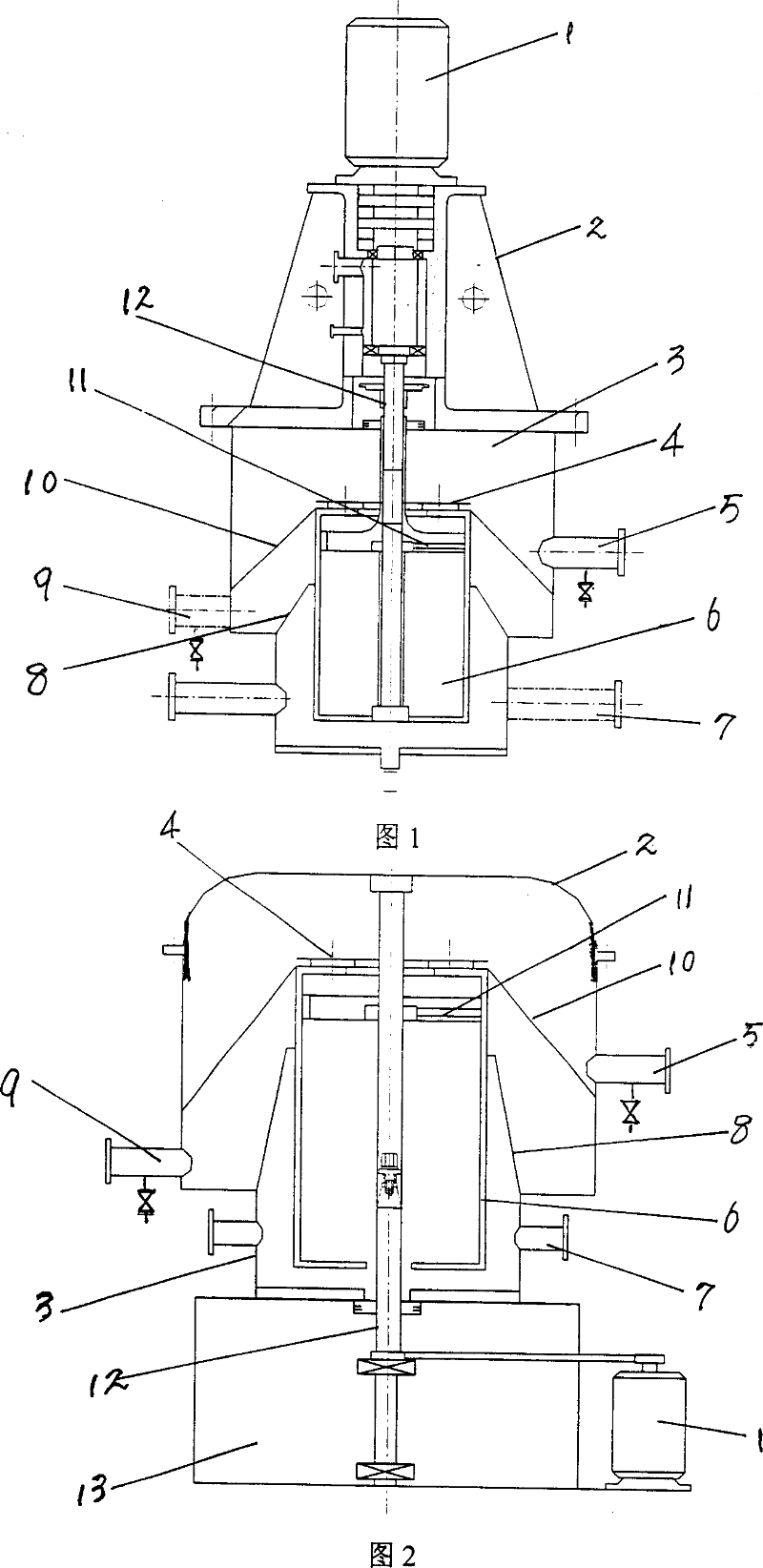

[0011] The structure of the lower drive type centrifugal extractor for chemical industry operation proposed by the present invention is shown in FIG. The upper cover 2 is built-in and covered on the shell 3 of the extractor. The rotating drum 6 is installed in the center of the extractor shell 3, and the extractor shell 3 is buckled on the rotating drum 6, and the rotating drum 6 is linked with the motor 1 through the rotating shaft 12. A heavy phase collection ring 10 and a light phase collection ring 8 are provided between the extractor shell 3 and the drum shell 6, and a heavy phase outlet is provided on the extractor shell between the heavy phase collection ring 10 and the upper cover 2 of the extractor shell 5. A light phase outlet 9 is provided on the extractor shell between the heavy phase collection ring 10 and the light phase collection ring 8, and a two-phase inlet 7 is provided on the extractor shell between the light phase collection ring 8 and the bottom of the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com