Elevator control device

A control device, elevator technology, applied in the field of elevator control devices, to achieve the effect of preventing abnormal tilt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

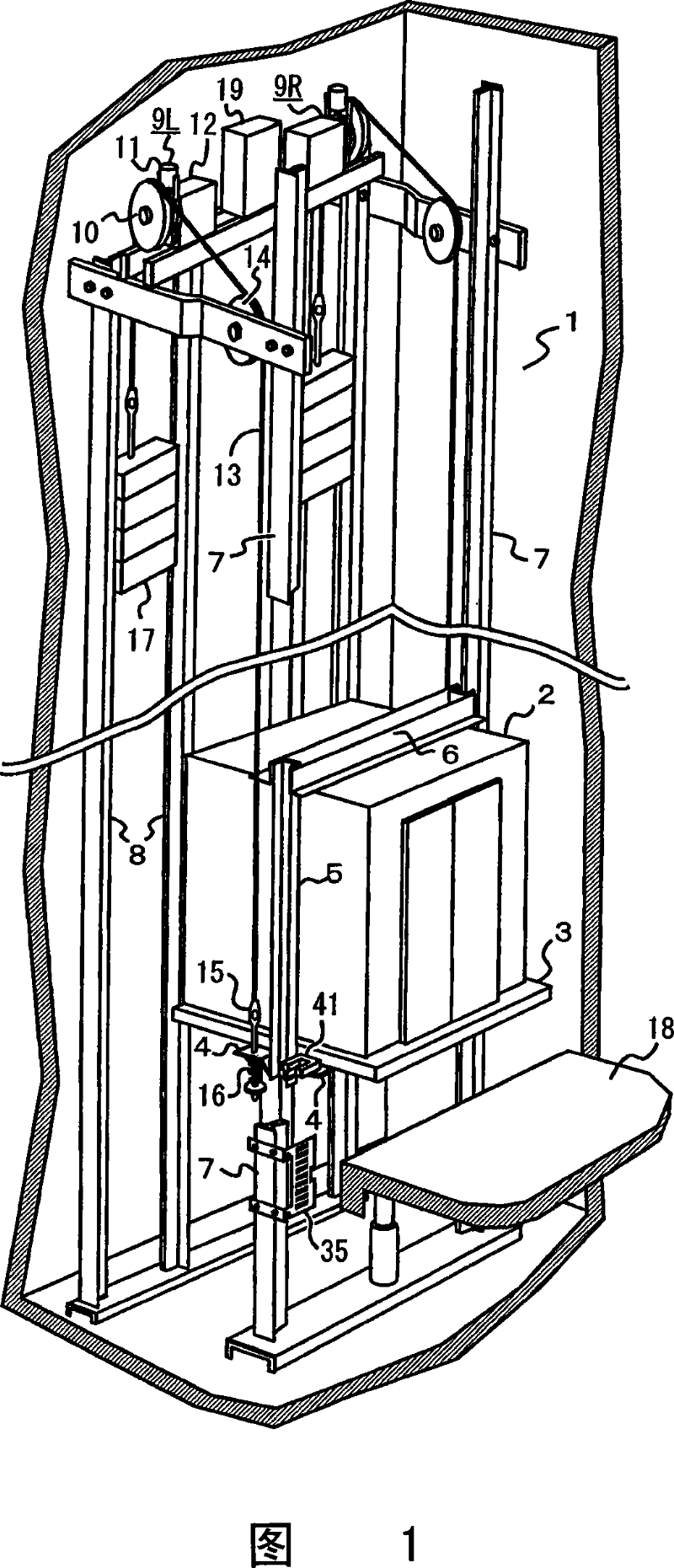

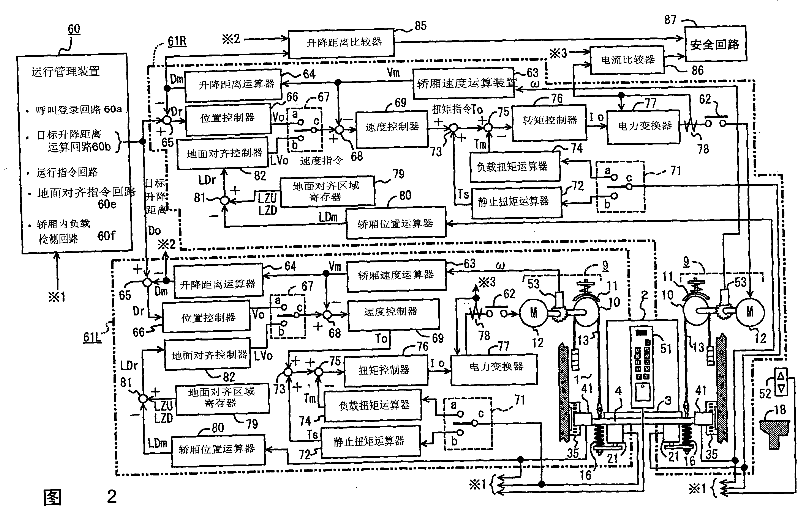

[0041] 1 to 11 show Embodiment 1 of an elevator control device having a plurality of hoisting machines according to the present invention. In this embodiment 1, two hoisting machines are specially arranged on the top of the elevator shaft, and the target lifting distance from the departure floor to the destination floor is jointly given to each hoisting machine to match the remaining distance from the current position to the destination floor. The speed is individually controlled for each hoist.

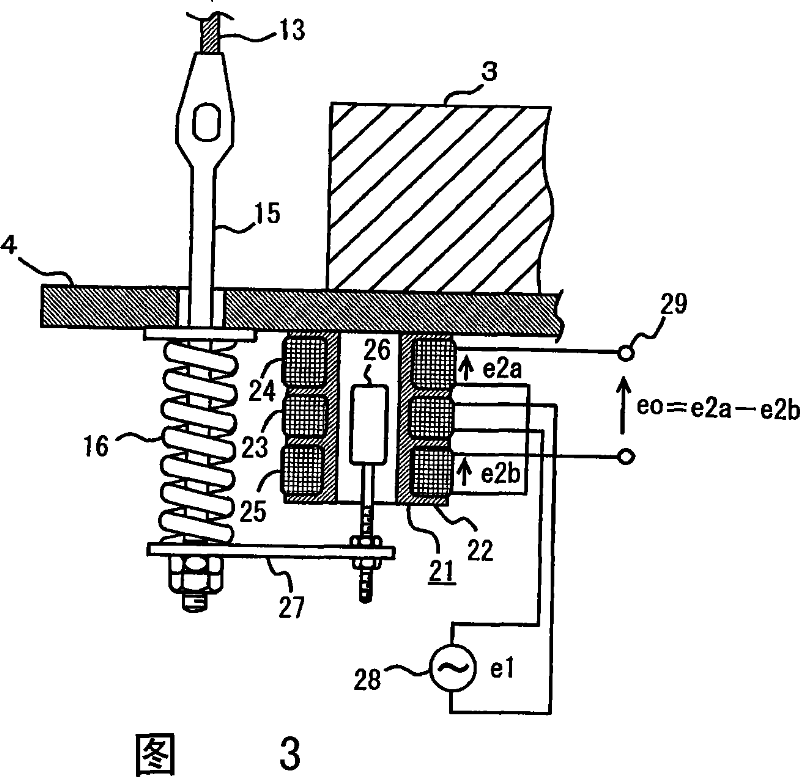

[0042]Fig. 1 is a perspective view showing the whole of an elevator control device. In the figure, 1 is the elevator shaft, 2 is the car, 3 is the floor of the car, 4 is the lower frame supporting the floor 3 of the car, 5 is the vertical frame erected on the left and right sides of the car 2, and 6 is the horizontal frame. The upper frame above the car 2. 7 is a pair of car guide rails fixed upright on the side walls of the elevator shaft on both sides of the car 2, and 8 is a cou...

Embodiment 2

[0082] 12 to 15 show Embodiment 2 of an elevator control device having a plurality of hoisting machines according to the present invention.

[0083] In this embodiment 2, at the beginning when the operation command is issued, the speed command is calculated as time goes by, and the winch is controlled uniformly. control.

[0084] Fig. 12 is a circuit block diagram showing the control device of the elevator, and 91 is a pair of left and right grating plates installed on the car guide rail 7 with the length facing the up and down direction. As shown in Fig. 13 in detail, from the up and down deceleration points PPu, PPd Cutting groove 36 is formed until the position of the floor ground. 100 is an operation management device, including: call registration circuit 60a; operation command circuit 60c; ground alignment command circuit 60e; car load detection circuit 60f; and optical sensor 41 and grid plate 91 A deceleration command circuit 60d that engages and issues a deceleration ...

Embodiment 3

[0100] Fig. 16 is a third embodiment of the elevator control device of the present invention.

[0101] In Embodiments 1 and 2 described above, the counterweights 17 are suspended on the left and right, respectively. In Embodiment 3, a common counterweight is suspended by the left and right main cables 13L and 13R. That is, both ends of the main cables 13L and 13R are fixed to the common car 2 and the common counterweight 17A.

[0102] In the above-mentioned third embodiment, the weight of the counterweight 17A is set in the same manner as in the first embodiment, and even if one of the brakes 11 does not operate, the car 2 with the rated load Wf can be brought to a standstill by only the other brake 11 . Especially in the present embodiment 3, the counterweight 17A is common to the left and right main cables 13L, 13R, so only a pair of counterweight guide rails 8 is sufficient, which can reduce the installation work.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com