Deviation rectifying method of tyre type container gantry crane

A technology for gantry cranes and containers is applied in the field of deviation correction of rubber-tyred container gantry cranes, which can solve the problems of high cost, direction correction, and difficulty for operators to observe marking lines, and achieves good deviation correction effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

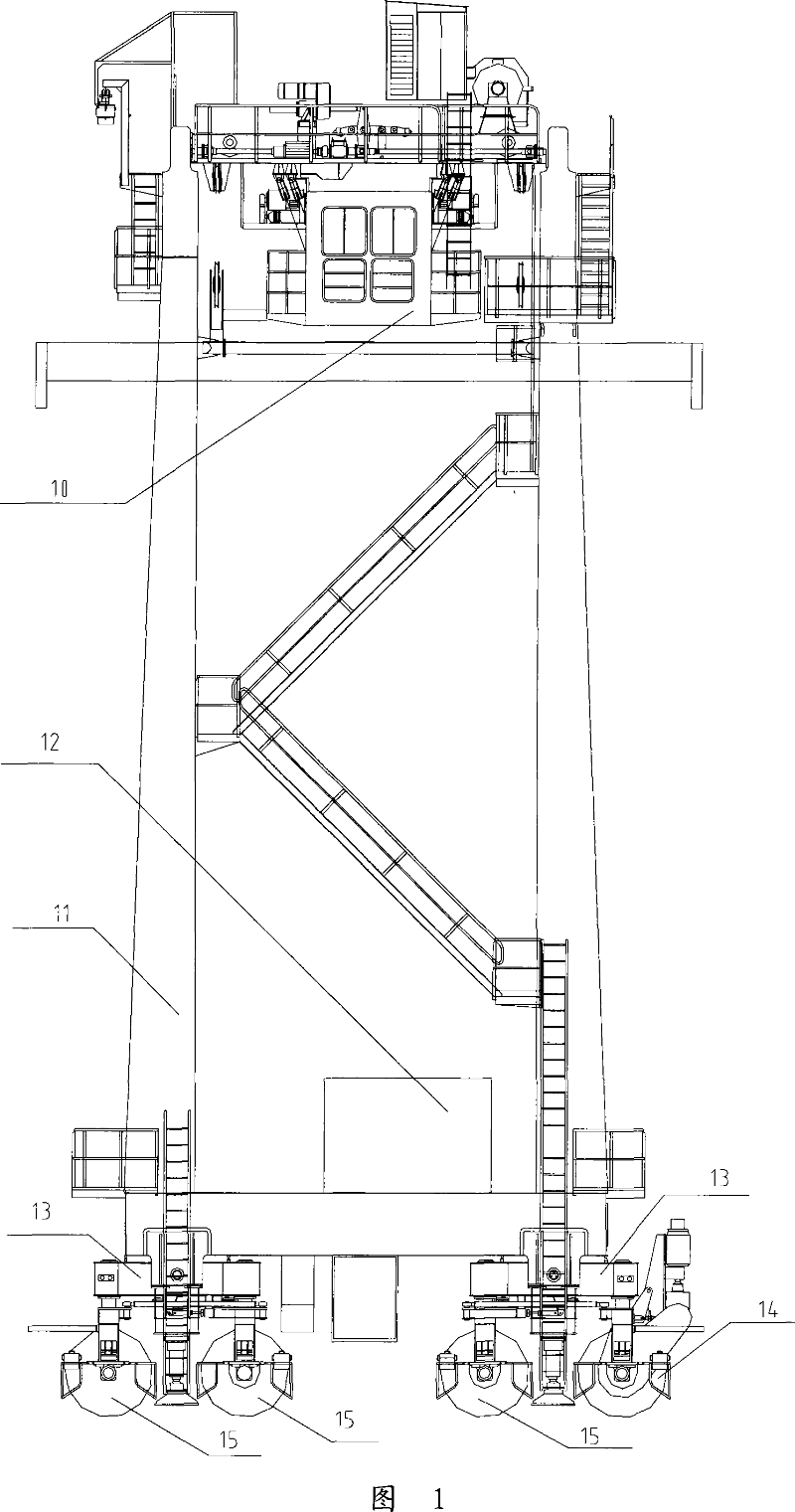

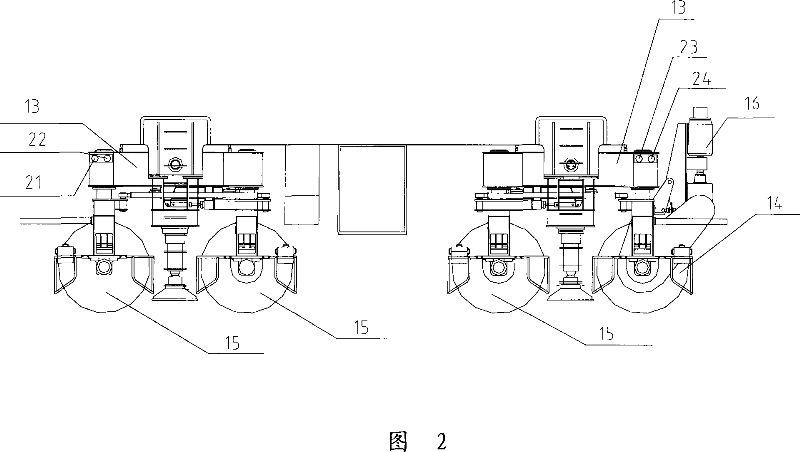

[0028] Rubber Tyred Gantry Crane (RTG for short) is a special equipment used for container loading and unloading in the container terminal yard, and can also be used as a crane transportation machine for general yards. Its appearance is shown in Figure 1. The crane is supported by eight rubber tires, powered by diesel generator set or shore power, and used as the driving power of the machine after AC frequency conversion.

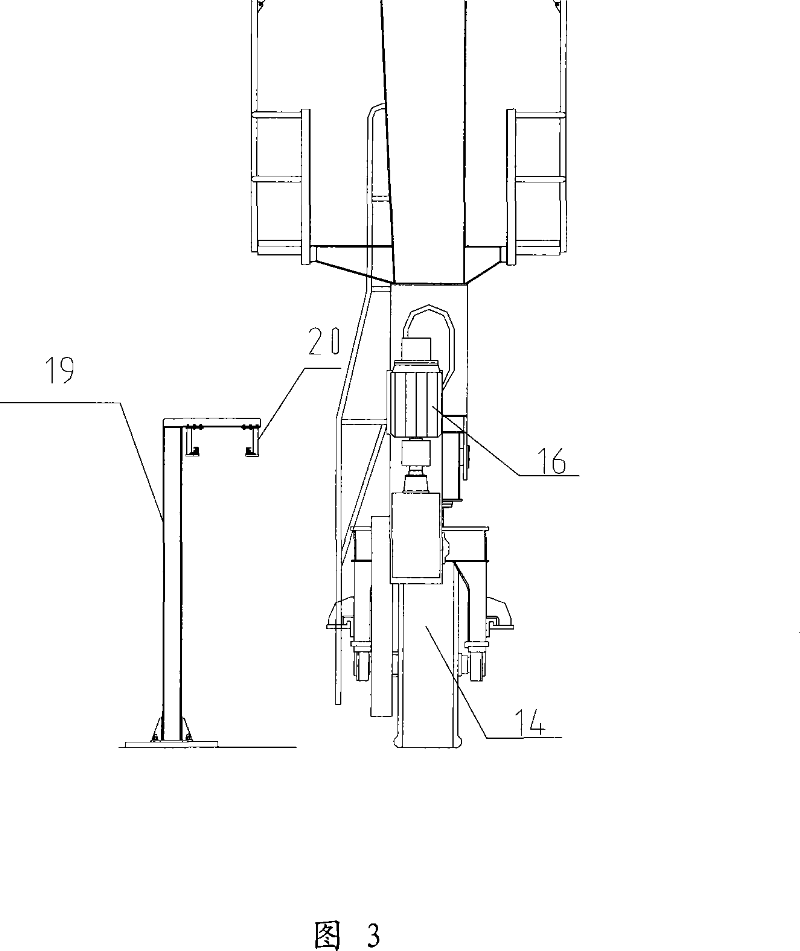

[0029] First of all, it should be noted that, in order to avoid cumbersome description, the crane in the present invention refers to a rubber-tyred container gantry crane. Below, the principle of the present invention is briefly described: the present invention installs an ultrasonic sensor on the crane, uses the ultrasonic sensor to detect the distance between the crane and the position reference object, and compares the distance with the preset distance, thereby generating and sending different The detection signal is sent to the controller, and the contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com