Cloth-pipe processing method and device

A technology of processing equipment and processing methods, which is applied to mechanical equipment, tools for sewing clothes, hoses, etc., can solve the problems of high material cost, insufficient artistic effect, and weak artistic expression, and achieve low processing cost, Conducive to popularization and application, processing method and simple effect of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

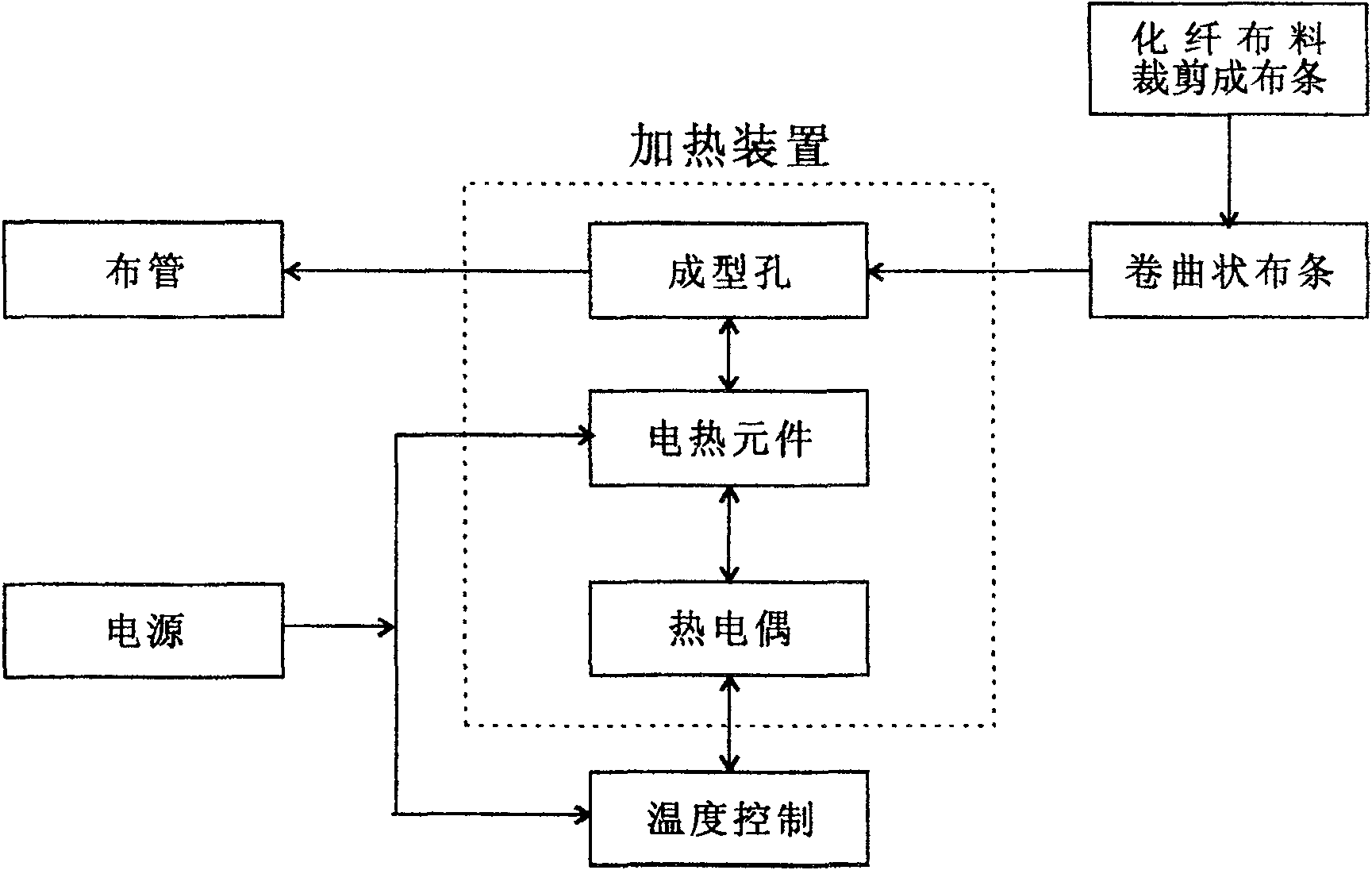

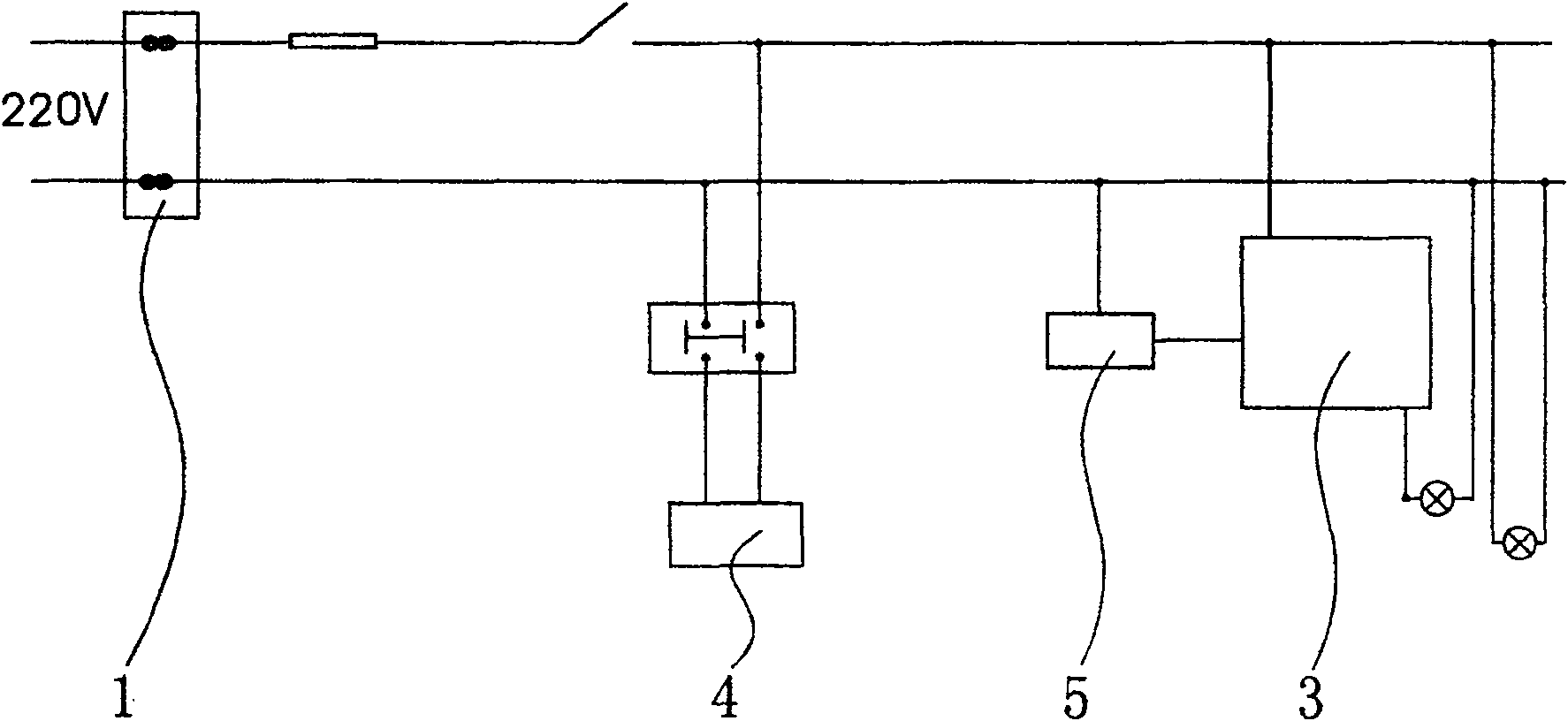

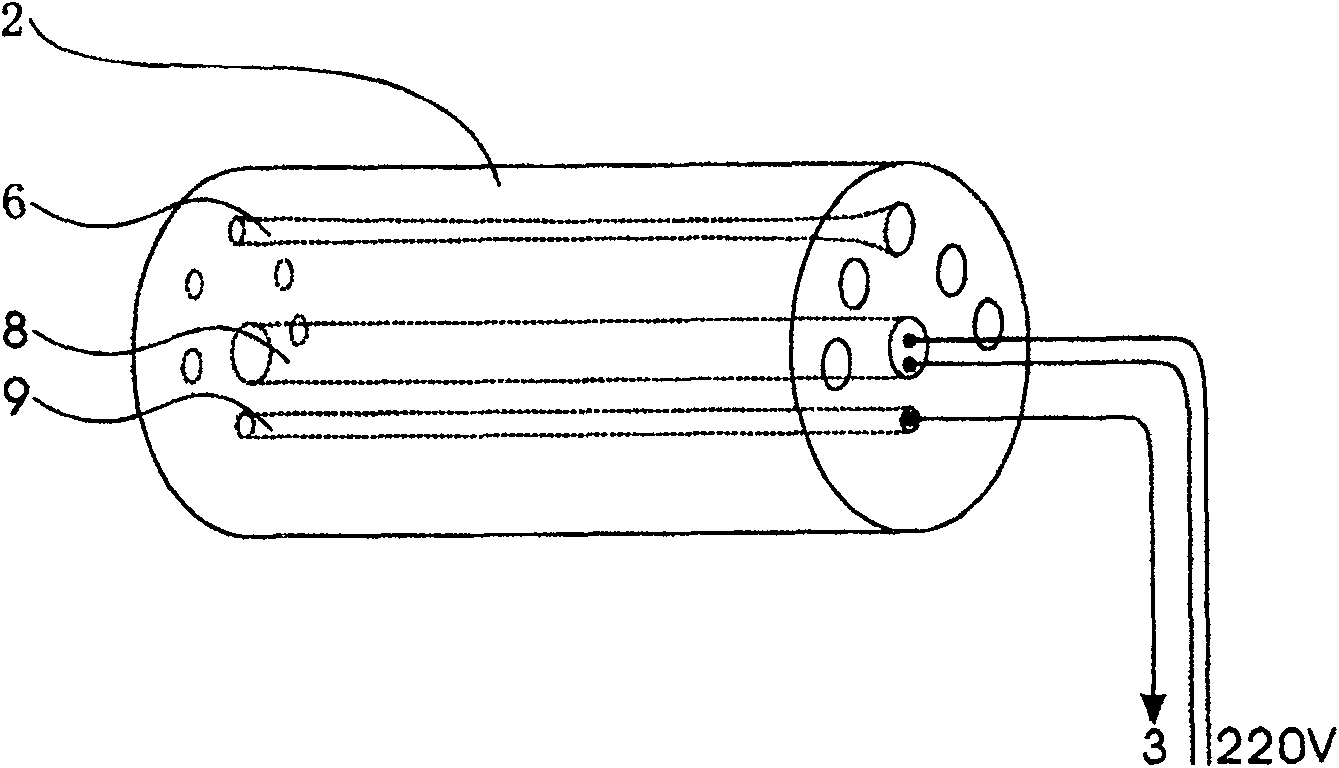

[0019] The cloth pipe provided by the present invention is processed by cutting chemical fiber cloth into cloth strips, and is characterized in that: the cloth pipe is a cylindrical pipe formed by curled chemical fiber cloth strips with cloth edges bonded or cloth surfaces overlapped. The two long sides of the cloth strip are in contact with each other to form a curled cloth strip. The burrs of the chemical fiber cloth strips are melted at a certain temperature by the processing equipment, and the one-time bonding is formed into a cylindrical pipe; another cloth pipe provided by the invention is processed by cutting the chemical fiber cloth into cloth strips, and is characterized in that : The curled cloth strips overlapped by the cloth surface pass through the processing equipment to lose the natural elasticity of the chemical fiber cloth itself at a certain temperature, and are formed into a cylindrical tube at one time. The cloth pipe can be used to replace the existing col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com