Pipeline of composing metal with polypropene

A composite pipe and polypropylene technology, which is applied in the field of graft modification of polypropylene materials, can solve the problem that the interface is not easy to be firmly composited, and achieve reliable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

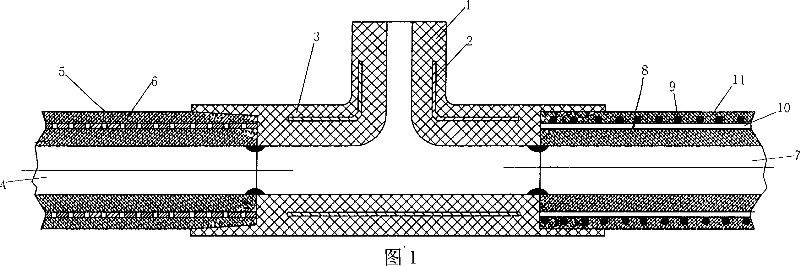

[0031] Fig. 1 has provided the figure of embodiment 1 of the present invention. Referring to Fig. 1, there is a cylindrical frame 2 rolled and welded by a steel plate with holes in the tee pipe fitting 1, and a polypropylene continuum 3 with polar groups passes through the hole on the cylindrical pipe frame 2 and the inner part of the cylindrical frame. , The outer surface is firmly bonded and covered to form the pipe wall. The pipe 4 has a steel plate metal cylindrical framework 5 with holes, and the polypropylene continuum 6 with polar groups passes through the cylindrical framework 5 and is firmly bonded to its inner and outer surfaces and covers it to form a pipe wall. In the pipe 7, there is a metal cylindrical frame 10 formed by welding the latitudinal steel wire 8 around the radial steel wire 9, and the polypropylene continuum 11 with polar groups passes through the hole on the metal cylindrical frame 10 and the inside, The outer surface is firmly bonded and clad to fo...

Embodiment 2

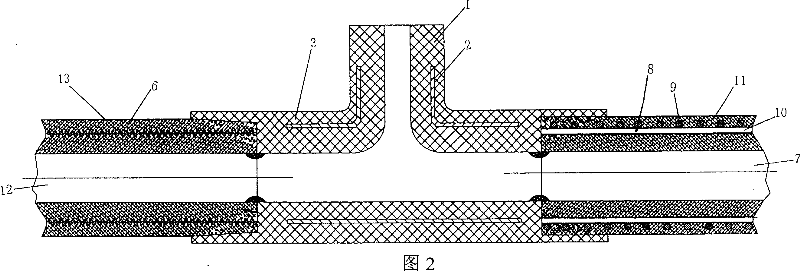

[0040] Fig. 2 has provided the figure of embodiment 2 of the present invention. Embodiment 2 is basically the same as Embodiment 1. The difference is that the metal skeleton 13 in the pipe 12 is a cylindrical skeleton in which radial steel wires are wound by weft steel wires.

[0041] The core tube with a diameter of φ200 is produced by polypropylene with polar groups in advance, and the steel wires of polypropylene coated with polar groups are wound left-handed and right-handed on the core tube to form a cross grid. The core tube is heated, and at the same time, the cross extruder is used to extrude polar polypropylene to cover the steel wire, and at the same time, the hole is filled with polar polypropylene to make it firmly bond and cover the cross steel wire, and at the same time pass through the mesh The holes in the grid are melted and connected with the inner core tube to form a composite pipe.

[0042]The helically wound steel wire can also not be left-handed and rig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com