Application of electromagnetic field for improving life of metallic material

A metal material and electromagnetic field technology, applied in the field of metal material processing, can solve problems such as deformation, element burning, incomplete phase transformation, etc., and achieve the effect of increasing service life, improving wear resistance, and obvious effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

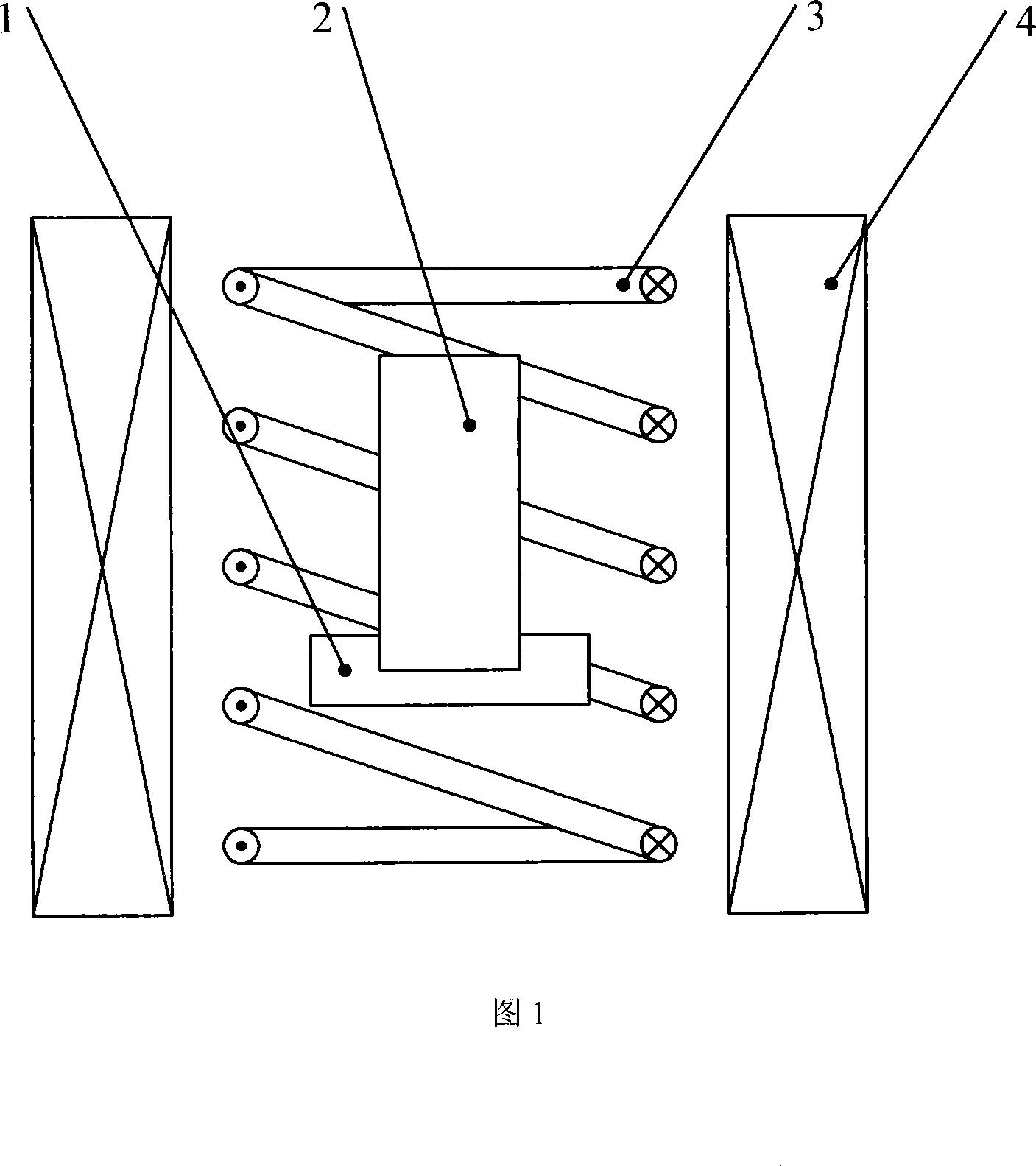

Image

Examples

Embodiment 1

[0018] Take 20 pieces of hard alloy turning blades KC9110 used in the machining industry, and stick them on the fixture platform through double-sided adhesive tape. The low-frequency excitation power supply outputs 80A alternating current, the frequency is 30Hz, and the number of turns of the low-frequency excitation coil is 350 turns; the output frequency of the induction power supply is 30KHz. Output power 5Kw, induction coil 6 turns; processing time 240s. The processed turning blades and the untreated turning blades produced in the same batch were processed under the same working conditions to process 45# steel shafts for comparative tests. The results showed that the untreated blades processed 200 pieces on average, and the processed Each blade processes 420 pieces on average, and the service life is increased by 1.1 times.

Embodiment 2

[0020] Take 20 pieces of hard alloy turning blades KC9225 used in the machining industry, and stick them on the fixture platform through double-sided adhesive tape. The low-frequency excitation power supply outputs 80A alternating current, the frequency is 30Hz, and the number of turns of the low-frequency excitation coil is 350 turns; the output frequency of the induction power supply is 30KHz. Output power 5Kw, induction coil 6 turns; processing time 240s. The processed turning blades were compared with the untreated turning blades produced in the same batch to process stainless steel sleeves under the same working conditions. The results showed that the untreated blades processed an average of 75 pieces per piece, and the processed blades On average, 240 pieces are processed per piece, and the life span is increased by 2.2 times.

Embodiment 3

[0022] Take 20 pieces of KY1310 carbide turning blades used in the machining industry, and stick them on the fixture platform through double-sided adhesive tape. The low-frequency excitation power supply outputs 80A alternating current, the frequency is 30Hz, and the number of turns of the low-frequency excitation coil is 350 turns; the output frequency of the induction power supply is 30KHz. Output power 5Kw, induction coil 6 turns; processing time 240s. The processed turning blades were compared with the untreated turning blades produced in the same batch to process the gray cast iron cylinder under the same working conditions. The results showed that the untreated blades processed 180 pieces on average, and the treated blades An average of 280 pieces are processed per blade, and the service life is increased by 0.56 times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com