Driving system of LCD and power supply

A liquid crystal display, power-driven technology, applied in static indicators, instruments, etc., can solve the problems of high cost of power-driven system and high cost of power-driven system of liquid crystal display

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

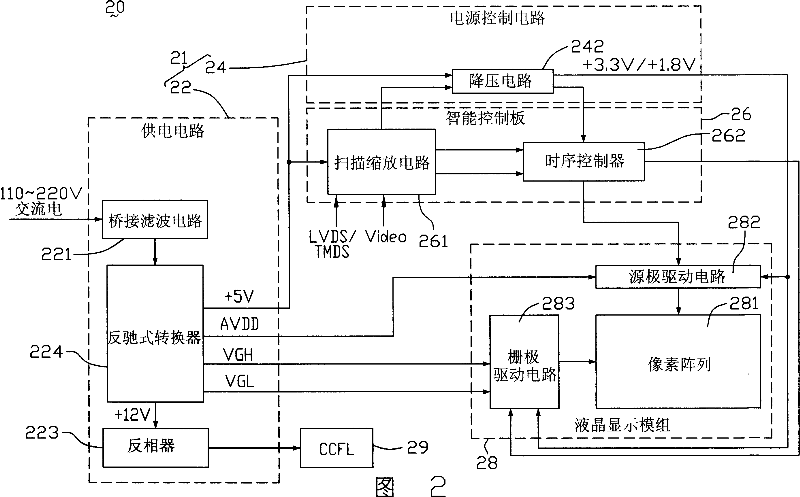

[0017] FIG. 2 is a schematic diagram of the circuit structure of a preferred embodiment of the liquid crystal display of the present invention. The liquid crystal display 20 includes a power drive system 21 , an intelligent control board 26 and a liquid crystal display module 28 . The power drive system 21 provides power for the liquid crystal display 20 . The intelligent control board 26 is used to control the driving circuit of the liquid crystal display module 28 .

[0018] The liquid crystal display module 28 includes a pixel array 281 , a source driving circuit 282 and a gate driving circuit 283 . The source driving circuit 282 and the gate driving circuit 283 jointly drive the pixel array 281 . The gate driving circuit 283 needs to receive the gate working voltage VGH of +15.xV or +24.xV and the gate working voltage VGL of -10.xV or -6.xV, so as to output the scanning signal to the pixel array 281 . The source driving circuit 282 needs to receive the main operating vo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com