Catalytically coated particle filter and method for producing the same and its use

A particle filter and catalyst technology, applied in catalyst activation/preparation, chemical instruments and methods, dispersed particle filtration, etc., can solve the problems of activity loss, palladium poisoning, low fresh activity, etc., and achieve the effect of good catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Example 1: (filter E1)

[0043] To prepare a filter according to the present invention, first, a third filter substrate was uniformly coated with a platinum catalyst over its entire length in the same manner as in Comparative Example 1. However, the platinum loading was reduced to 3.1 g / l (88 g / ft 3 )s level. Then, in order to form the first catalyst, palladium nitrate is further used to impregnate the length of 25.4 mm which will be the end of the gas inlet side of the filter to have 0.42 g / l (12 g / ft 3 ) palladium content. Therefore, the total precious metal content of the filter is also 3.18g / l (90g / ft 3 ). The first catalyst formed by further impregnation has 3.53 g / l (100 g / ft 3 ) of the noble metal concentration, the palladium / platinum ratio is 1:7.3. In this case, the second catalyst was formed from a platinum catalyst that was not further impregnated with palladium. Therefore, its palladium / platinum ratio is 0.

[0044] The light-off temp...

Embodiment 2

[0053] Example 2: (filter E2)

[0054] First, the filter substrate was uniformly coated with the platinum catalyst of Comparative Example 1 so that the platinum concentration was 3.1 g / l (88 g / ft 3 ). Then, further use palladium nitrate to impregnate the length of 25.4 mm at one end of the inlet side of the filter so as to have 0.42 g / l (12 g / ft 3 ) palladium content. Therefore, the total precious metal loading is also 3.18g / l (90g / ft 3 ). The first catalyst formed by further impregnation has 3.53 g / l (100 g / ft 3 ) of the noble metal concentration, the palladium / platinum ratio is 1:7.3.

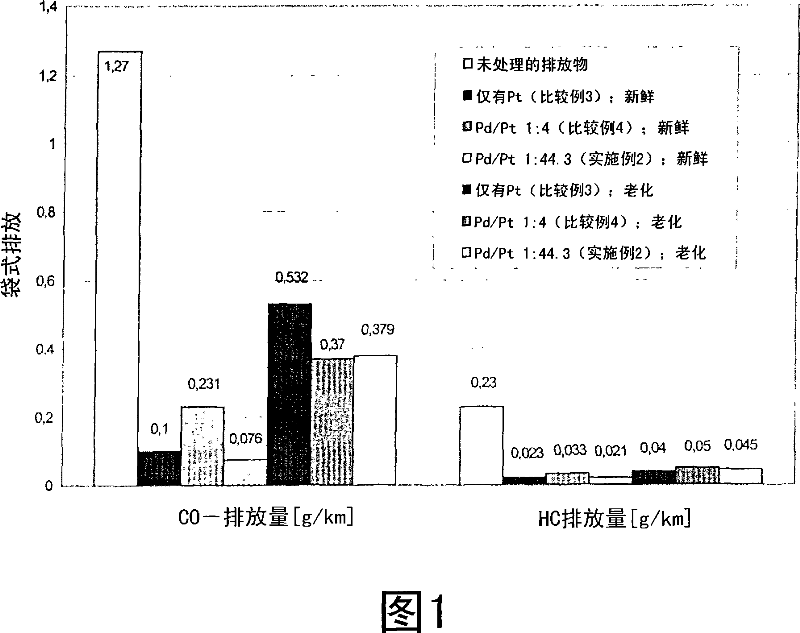

[0055] The catalytic activity of these filters was tested in the fresh state and after hydrothermal aging on a Euro III certified diesel passenger car with a 100 kW 2.21 common rail diesel engine. This vehicle has a factory installed oxidation catalyst and particulate filter. Instead of the light-off temperature, the vehicle is measured for emissions during the NEDC d...

Embodiment 3

[0058] A second set of filters C3, C4 and E2 was prepared.

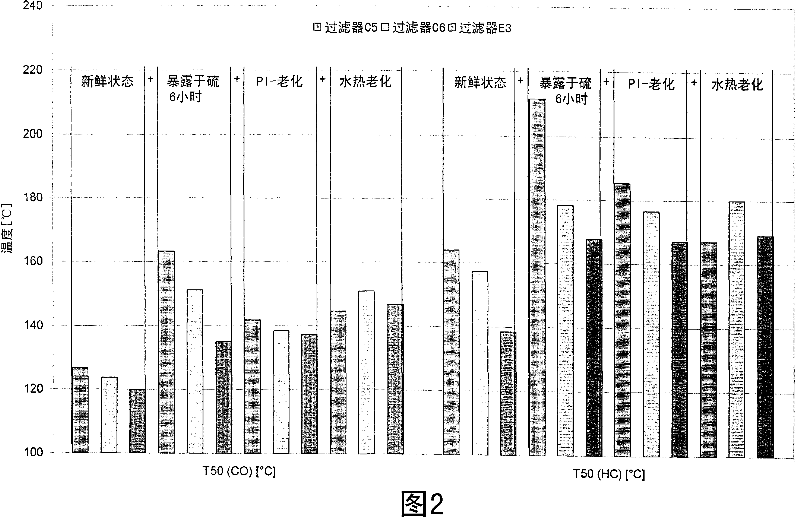

[0059] The light-off temperature of the filter without precatalyst was first measured in the fresh state with a direct injection diesel engine (2.2 l capacity) with exhaust gas turbocharging and charge cooling and a power of 100 kW. All filters were then exposed to sulfur for 6 hours at exhaust gas temperatures between 200° C. and 300° C. using diesel fuel containing 2400 ppm (by mass) sulfur in each case, and then measured again. The results are collected in Table 3.

[0060] filter

[0061] Clearly, the filter with a Pt-only coating has a similar fresh activity to the filter according to the invention which has been further impregnated with palladium on the inflow side. Filter C2 with a uniform Pd / Pt coating over the length of the filter is very sensitive to sulfur poisoning. The reason is that sulfur easily poisons palladium. This problem is substantially avoided if palladium is introduced according ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com