Boiler arrangement

A boiler and back wall technology, applied in the field of expansion boiler installation, can solve problems such as unachievable results, achieve the effect of reducing initial investment and maintenance work, and shortening the time when the boiler stops working

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

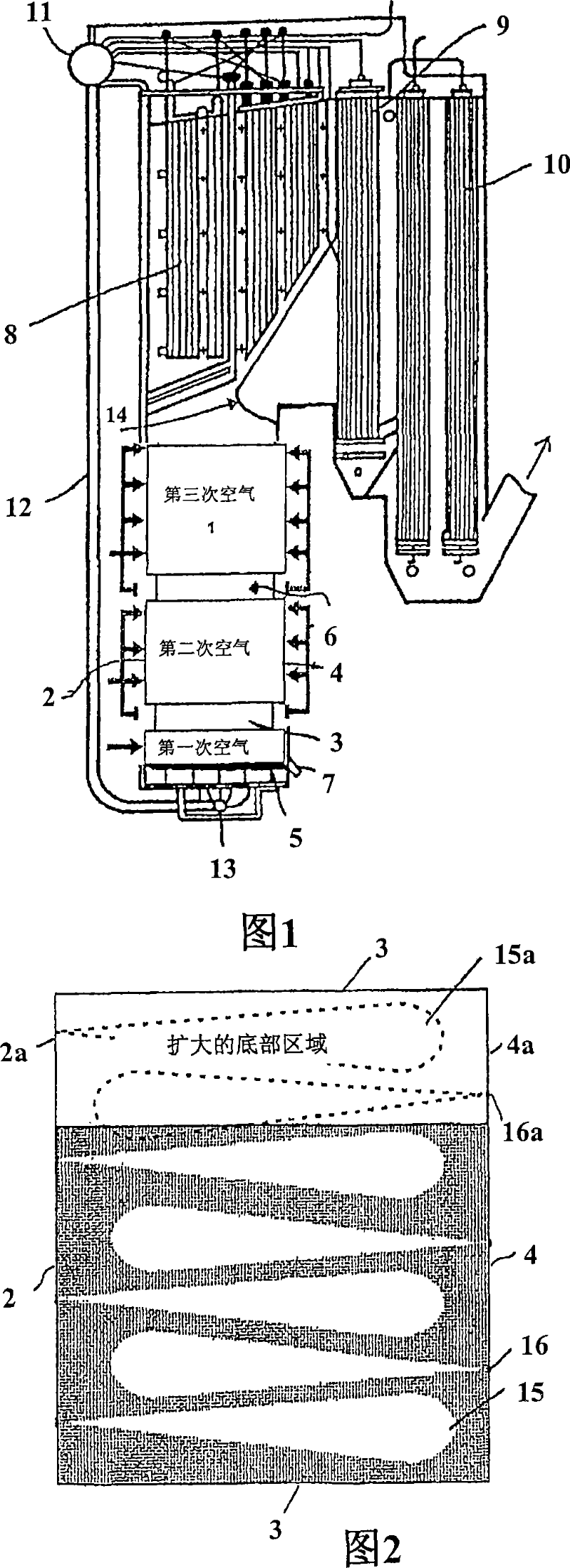

[0023] Figure 1 schematically shows a chemical recovery boiler structure with a furnace 1 defined by the following water tube walls: a front wall 2, two side walls 3 and a rear wall 4 and a bottom wall 5 which also constitutes the water tubes. Combustion air is fed into the furnace from several different heights as first, second and third air. Other air heights are also possible. Waste liquor, such as black liquor, is introduced via nozzles 6 between the second and third air zones. During the combustion process, a molten bed from the effluent is formed in the bottom 5 of the furnace, from where the melt is output via a melt delivery pipe 7 installed in the bottom of the furnace.

[0024] The heat recovery surface of the boiler, i.e. the superheater 8, is located above the furnace, while the rear wall 4 of the furnace accommodates the hot surface along the superheater, boiler tube bundle 9 and economizer 10 in the upper part of the furnace, where the emission of flue gases gen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com