Cooling device with carbon nanaotube coating and method of forming the same

A heat sink, carbon nanotube technology, applied in the direction of carbon nanotube, nanocarbon, nanotechnology, etc., can solve problems such as damage and component failure, and achieve the effect of effective dissipation, improvement of life and performance, and improvement of heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described more fully hereinafter with reference to the accompanying drawings, in which typical embodiments of the invention are shown. In the drawings, the shapes and thicknesses of layers may be exaggerated for clarity, and the same reference numerals are used to designate the same elements in the various drawings.

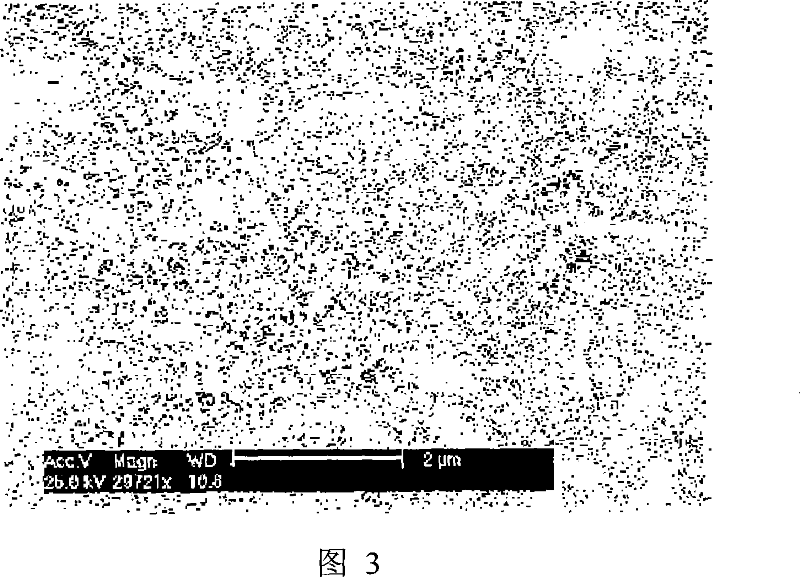

[0026] FIG. 3 is a photograph of a surface of a heat sink, on which carbon nanotubes are adsorbed, according to an exemplary embodiment of the present invention.

[0027] FIG. 3 shows fin surfaces after forming a heat sink including a plurality of fins and performing a dip plating process on the heat sink. In one embodiment, since carbon nanotubes are provided on the surface of the heat sink, compared with the existing heat sink with a planar structure, the heat exchange contact portion can be increased by hundreds to thousands of times. Also, the thermal conductivity of carbon nanotubes is 1800 to 6000 W / mK, and its thermal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com