Heat exchanger

A heat exchanger and heat exchange tube technology, applied in heat exchange equipment, heat exchanger shells, lighting and heating equipment, etc., can solve the problems of heat exchange efficiency limitation, production efficiency reduction, high waste rate, etc., to reduce water pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Hereinafter, it will be described in detail in combination with preferred embodiments of the present invention and accompanying drawings.

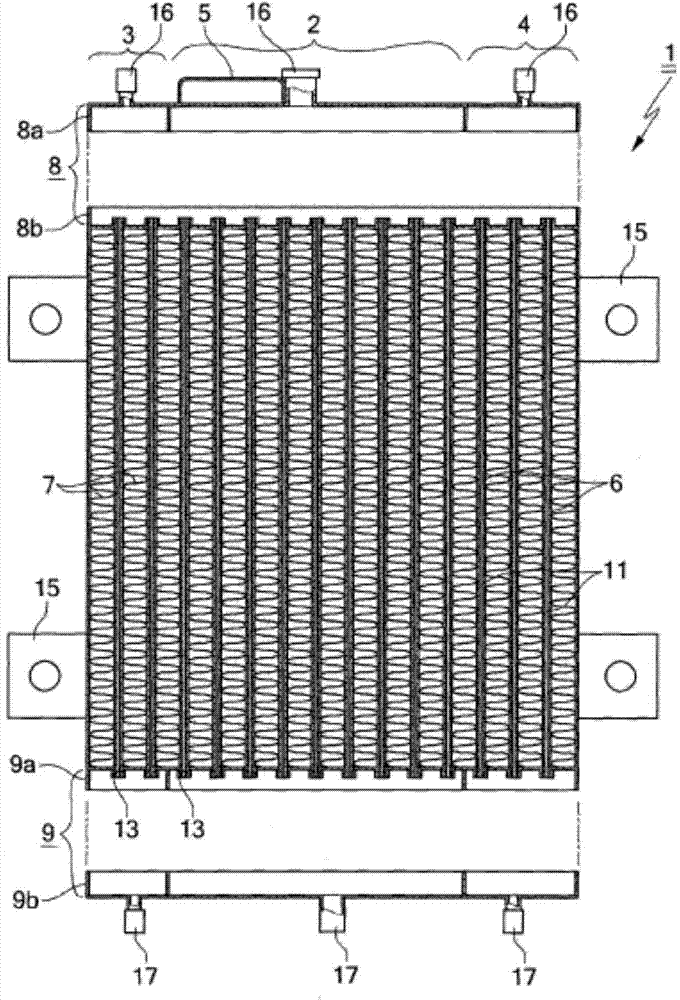

[0033] figure 1 It is a perspective view which shows a preferable example of the heat exchanger provided by this invention.

[0034] In other words, in the heat exchanger 1 of the present invention, the main body is injection-molded using a material such as nylon resin that has better heat dissipation than non-metallic aluminum.

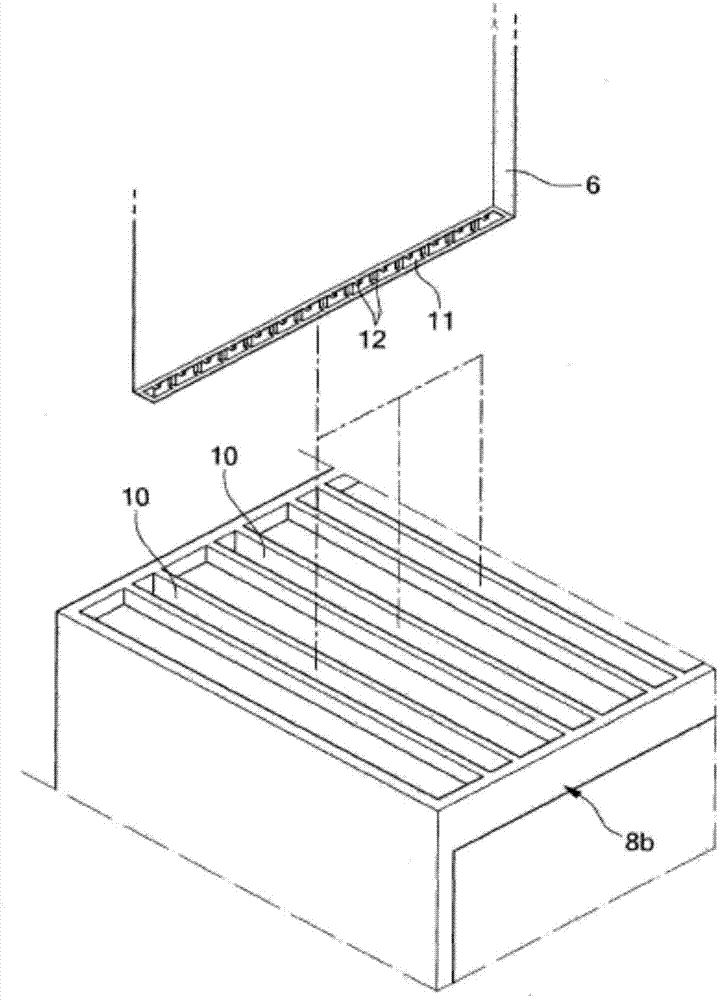

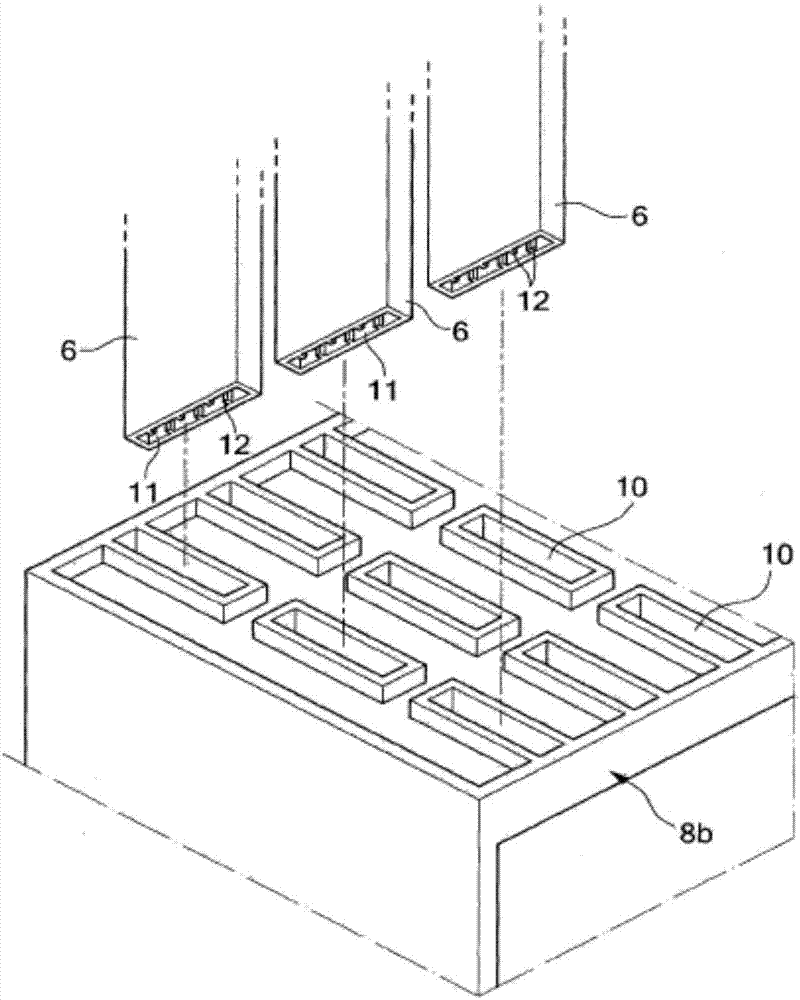

[0035] The above-mentioned heat exchanger 1 body includes: an upper body 8, which is injection-molded into a split type (split type); a lower body 9, which is additionally injection-molded; a plurality of heat exchange tubes 6, which are additionally extrusion-molded and other methods. Manufactured so as to be arranged between the upper body 8 and the lower body 9; a plurality of cooling fins 7 assembled between the above-mentioned heat exchange tubes 6 .

[0036] The above-mentioned upper body 8 is comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com