Higher degree roller ablet to control edge shape of steel band

A technology for controlling strips and steel edges, applied in the direction of rolls, metal rolling, manufacturing tools, etc., can solve the problems that cannot be formed, affect the wear of work rolls, edge thinning, and sudden contact pressure changes, and achieve low cost and simple transformation Convenience, small side thinning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

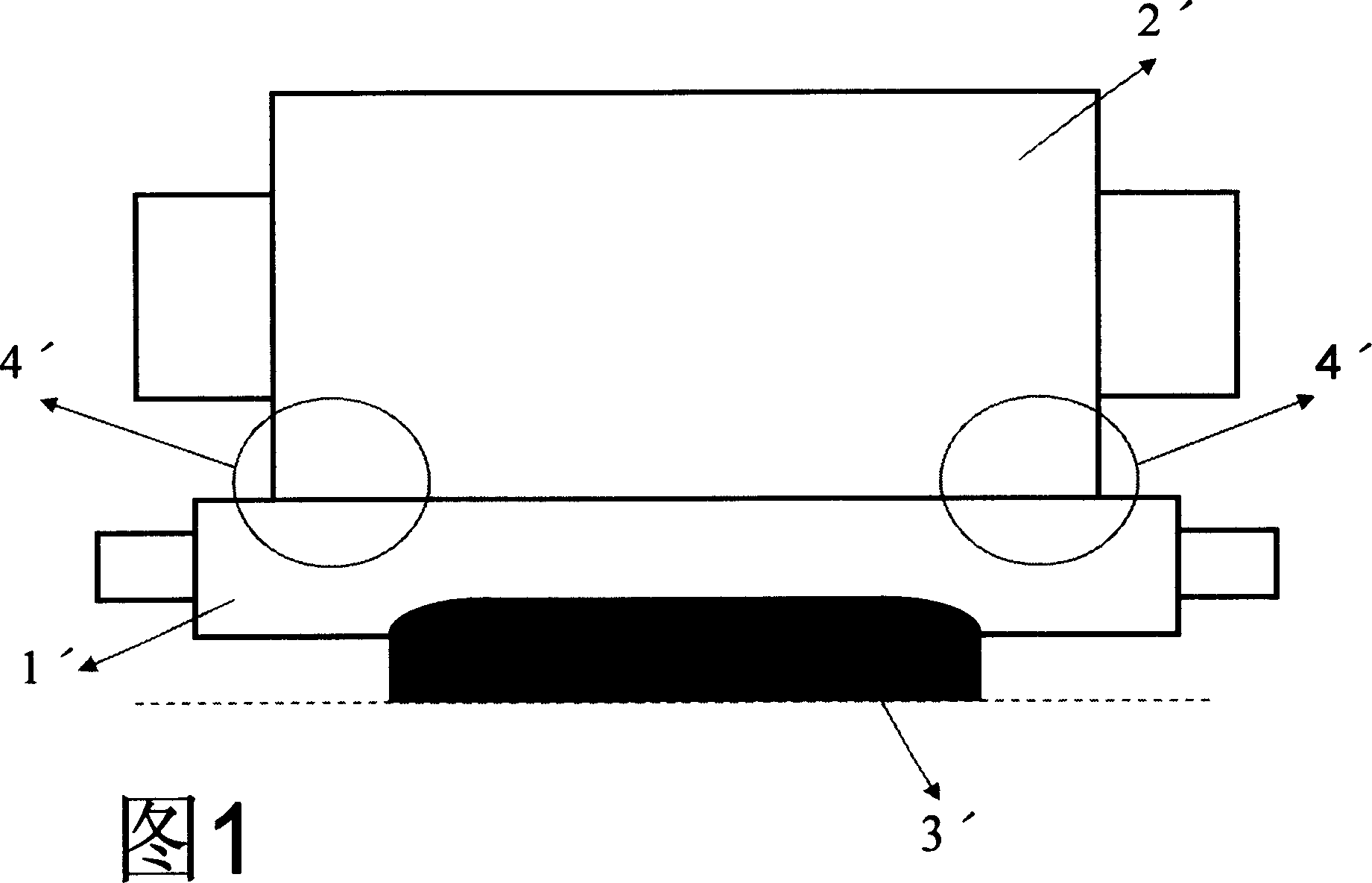

[0038] Please refer to Fig. 6, shown in Fig. 7, in this embodiment, the high-order shape roll (BEC) 10 that controls strip edge plate shape comprises work roll 11, back-up roll 12, and described work roll 11 is positioned at and described On the upper and lower sides of the rolled plate and strip 13 , the support rolls 12 are located on both sides of the work roll 11 for supporting the work roll 11 .

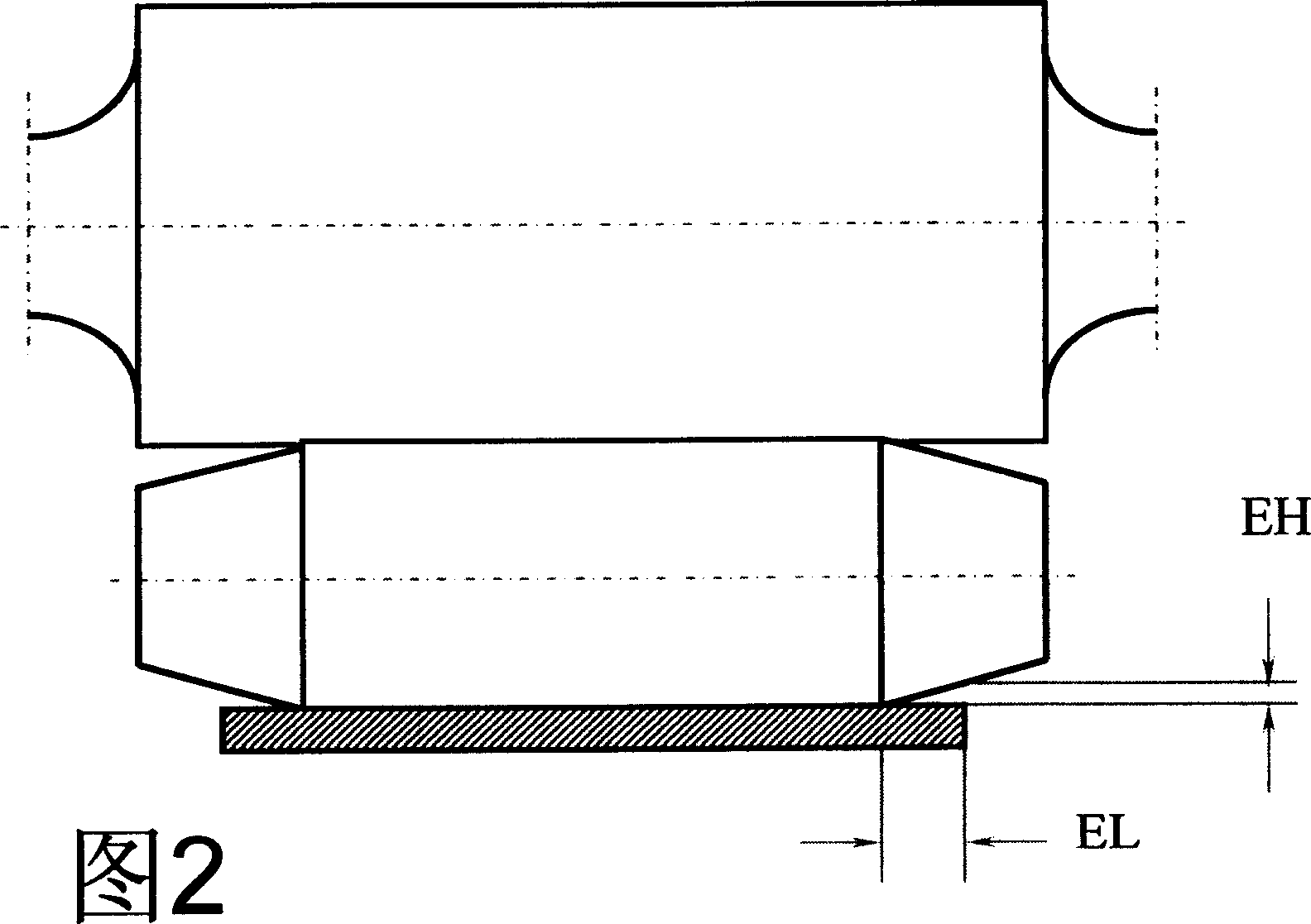

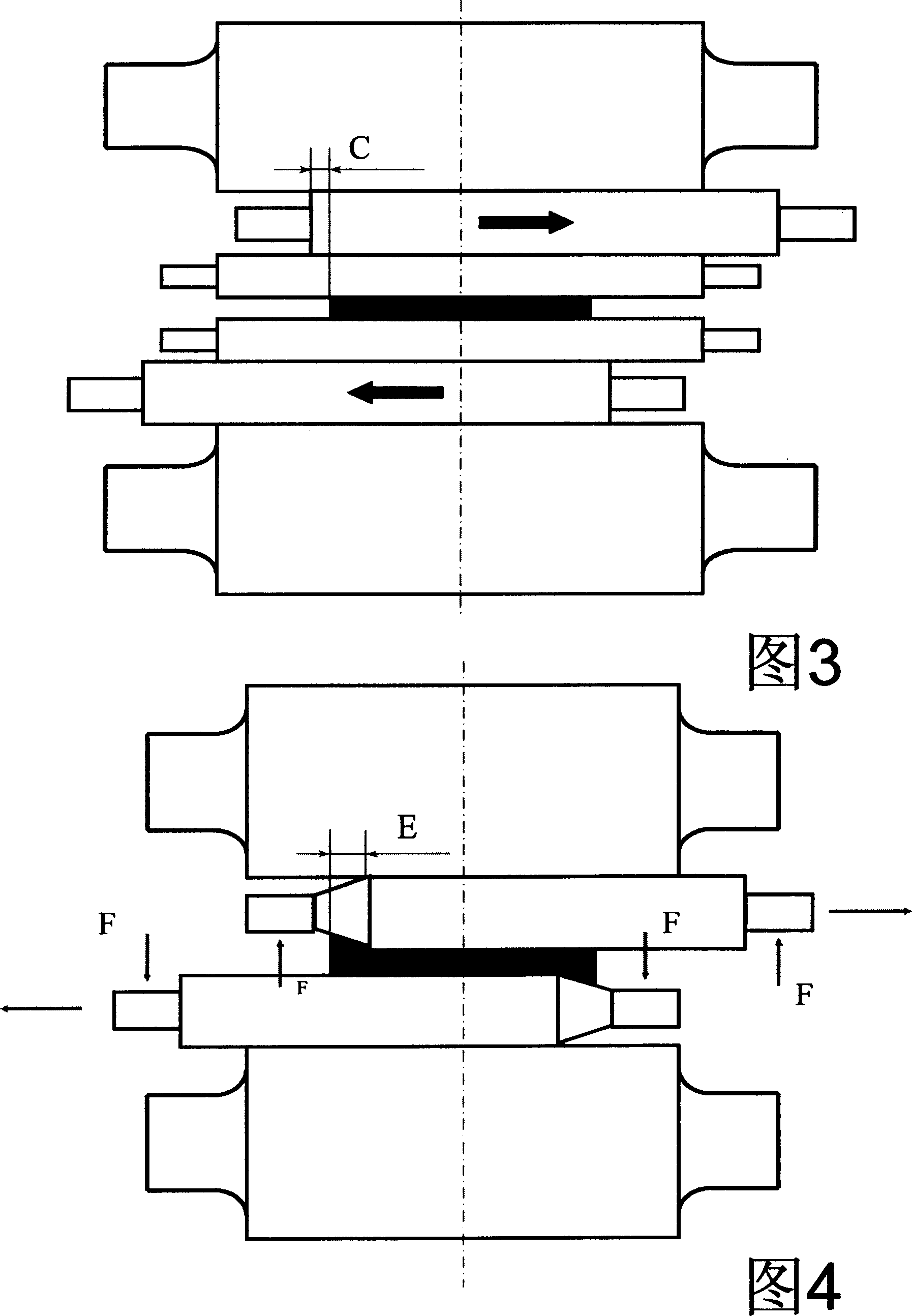

[0039] The shape of the roll end of the work roll 11 is a circular arc shape that compensates for the thinning of the rolled plate and strip 13 sides, and the roll shape curve is a smooth curve connected by two sections, one section of arc curve 111, and the other section is a straight line 112. At the intersection point O of the arc curve and the straight line, the derivative of the arc curve is zero.

[0040] Described work roll 11 comprises at least two (two groups), and the shape of a roll end of each (group) work roll 11 is the circular arc shape that compensates rolled pla...

Embodiment 2

[0048] Please also refer to Fig. 6 and Fig. 7, in this embodiment, the high-order shape roll 10 for controlling the shape of the edge of the strip includes a work roll 11 and a back-up roll 12, and the work roll 11 is located at the same position as the rolled The upper and lower sides of the plate and strip 13, the support rolls 12 are located on both sides of the work roll 11 for supporting the work roll 11.

[0049] The shape of the roll end of the work roll 11 is a circular arc shape that compensates for the thinning of the rolled plate and strip 13 sides, and the roll shape curve is a smooth curve connected by two sections, one section of arc curve 111, and the other section is a straight line 112. At the intersection point O of the arc curve and the straight line, the derivative of the arc curve is zero.

[0050]Described work roll 11 comprises at least two (two groups), and the shape of a roll end of each (group) work roll 11 is the circular arc shape that compensates r...

Embodiment 3

[0052] Embodiments 3 and 4 are basically the same as the first two embodiments, and will not be described one by one here. The difference is that the roll shape curve of the work roll in embodiment 3 is a y=1-cos ax function curve; while embodiment 4 The roll shape curve of the work roll is y = tan ax function curve.

[0053] Of course, the roll shape curve of the work roll of the present invention may also be other roll shape curves obtained by finite element simulation design and experiment correction.

[0054] Work roll of the present invention compares with the work roll in the traditional roll, and its advantage can find out from following analysis:

[0055] The roll shape curve of the work roll is a smooth curve. This is because the derivative of the arc curve at the intersection point of the arc and the straight line is zero, and there is no inflection point in the curve. Edge drop control of steel, while there is an inflection point in the roll shape curve of K-WRS, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com