Building block

A building block technology, which is applied in the direction of buildings, building components, building structures, etc., can solve the problems of low joint strength, wall integrity, insufficient crack resistance, and inconvenient horizontal reinforcement layout.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

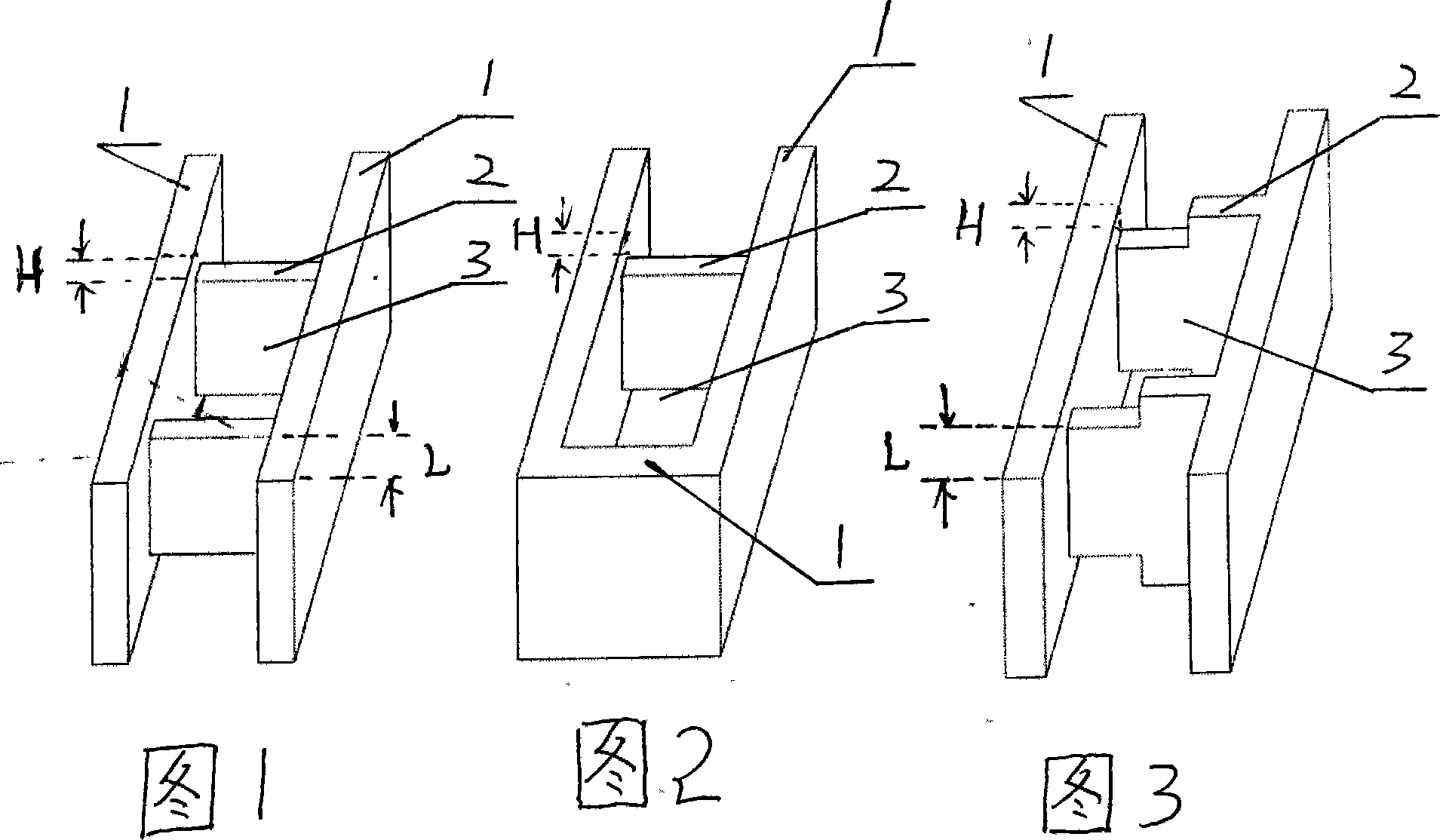

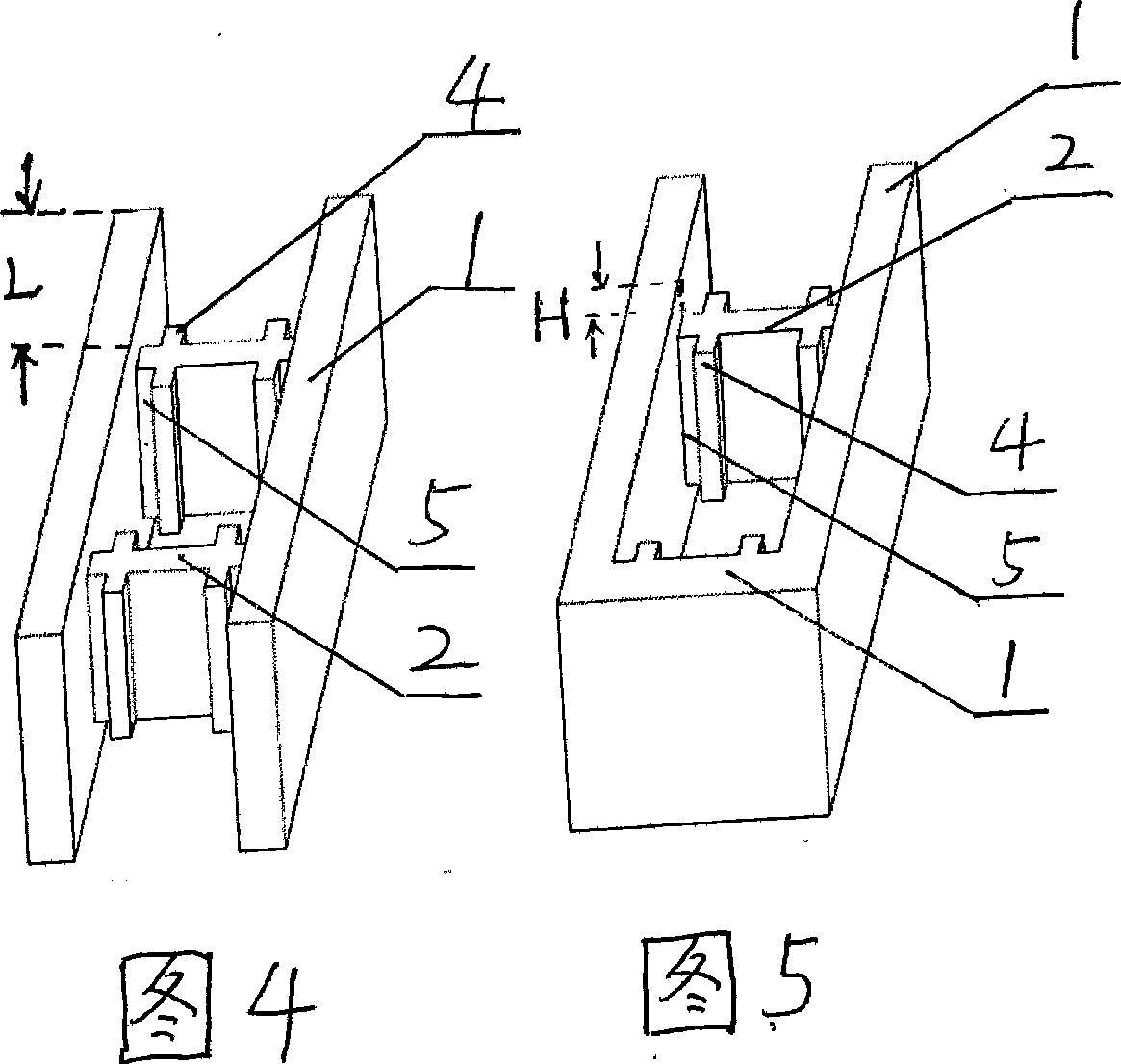

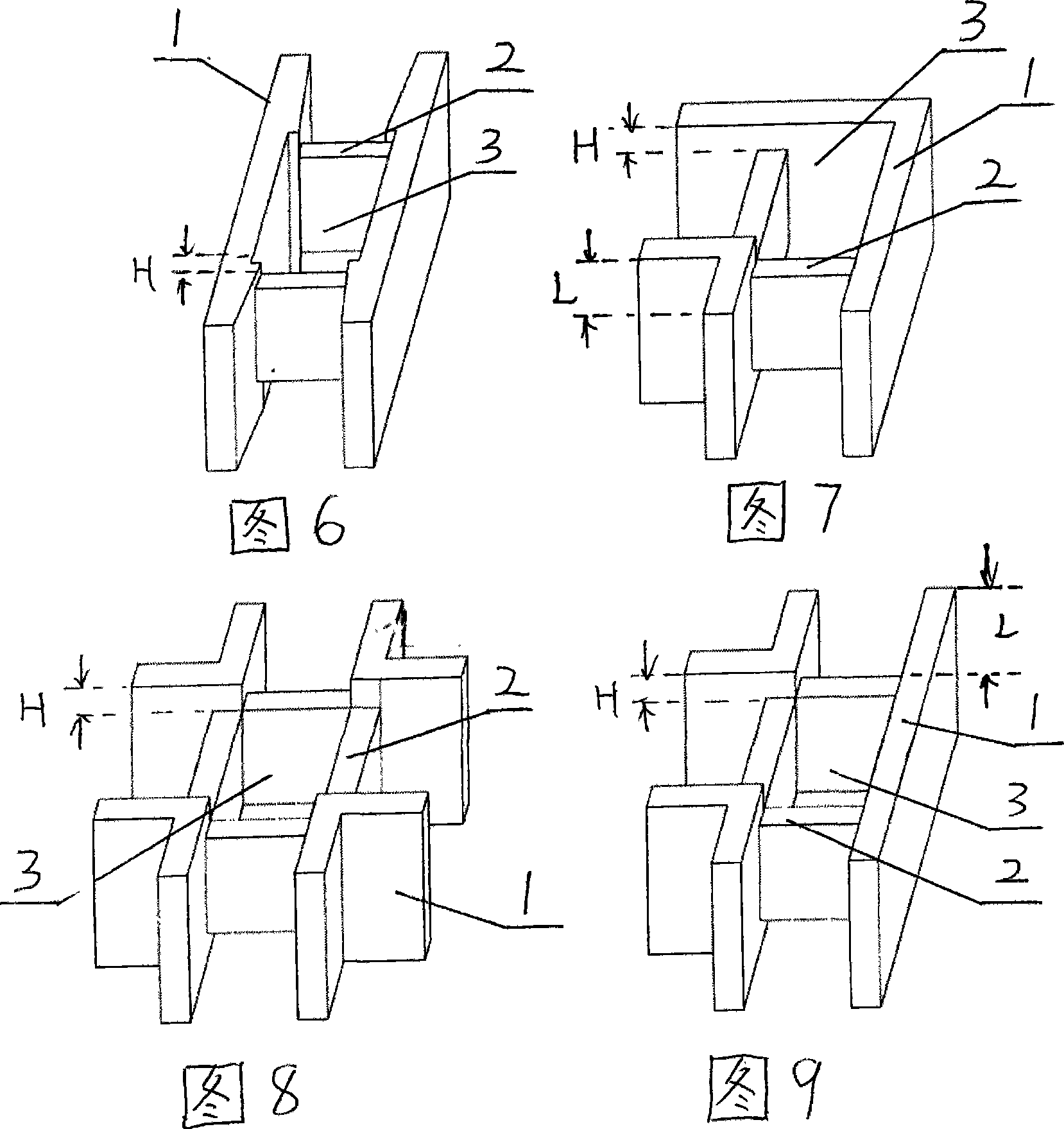

[0022] Referring to Fig. 1 - Fig. 14, the building block is composed of an outer wall 1 and an inner rib 2, the outer wall 1 and the inner rib 2 are connected to each other, and the height of the inner rib 2 is smaller than that of the outer wall 1, forming a height difference H. The inner rib 2 can be single or multiple. According to the needs, the height difference H can be set on the upper and lower parts of the block, or only on the upper or lower part of the block. The inner rib 2 can be partly or fully height Less than the height of the outer wall 1, the outer wall 1 and the inner rib 2 between the blocks or adjacent blocks form a block space 3, and the height difference H forms a transverse gap, which connects the block spaces 3 of each block, so that the space of each block The block spaces 3 can communicate with each other through the horizontal gaps, and the poured concrete can flow in the horizontal gaps, quickly filling up the block spaces 3 of each block, and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com