Capacitance-based fluid level sensor

A technology of liquid level sensor and sensor, which is applied in the direction of liquid level indicator for physical variable measurement, and can solve the problem of no float type sensor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Two embodiments of a fill level sensor designed according to the invention will now be described in the form of an oil level sensor for use in a striker. Of course, it should be understood that many different embodiments of the invention are also conceivable, which can also be used as liquid level sensors in many other applications.

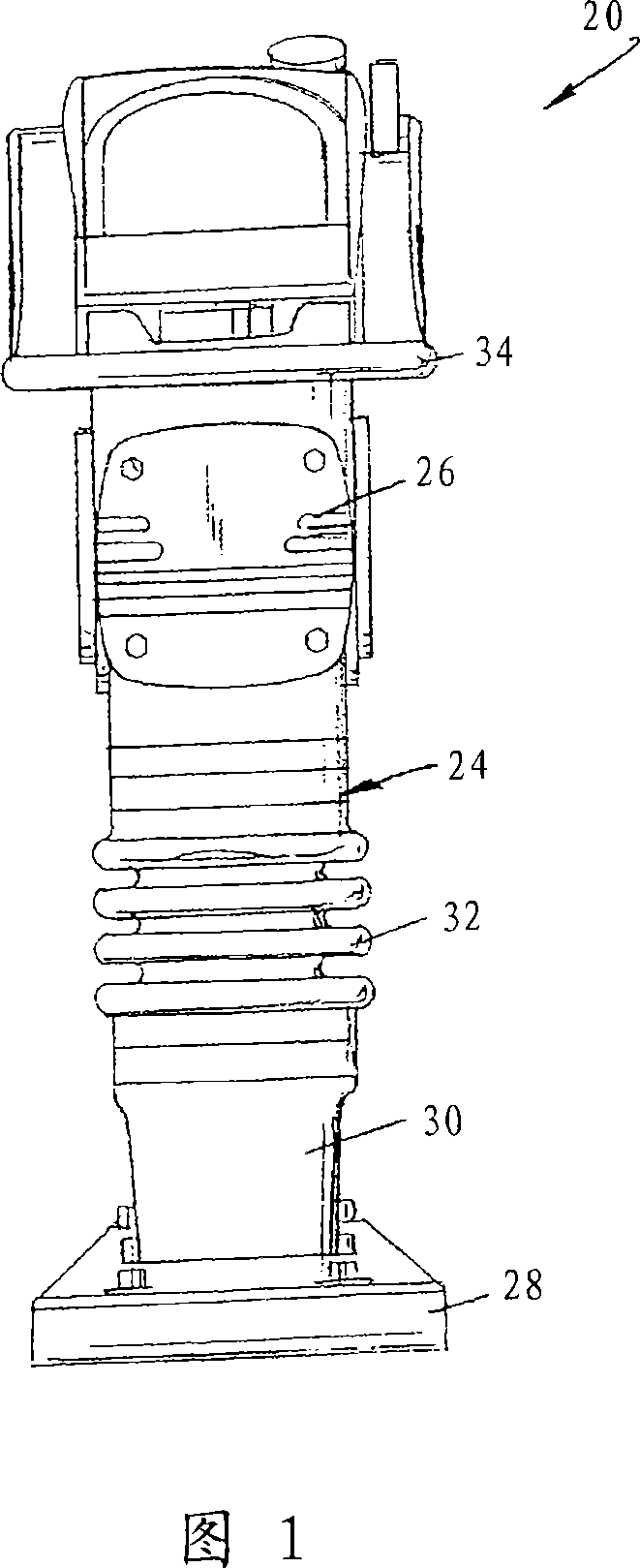

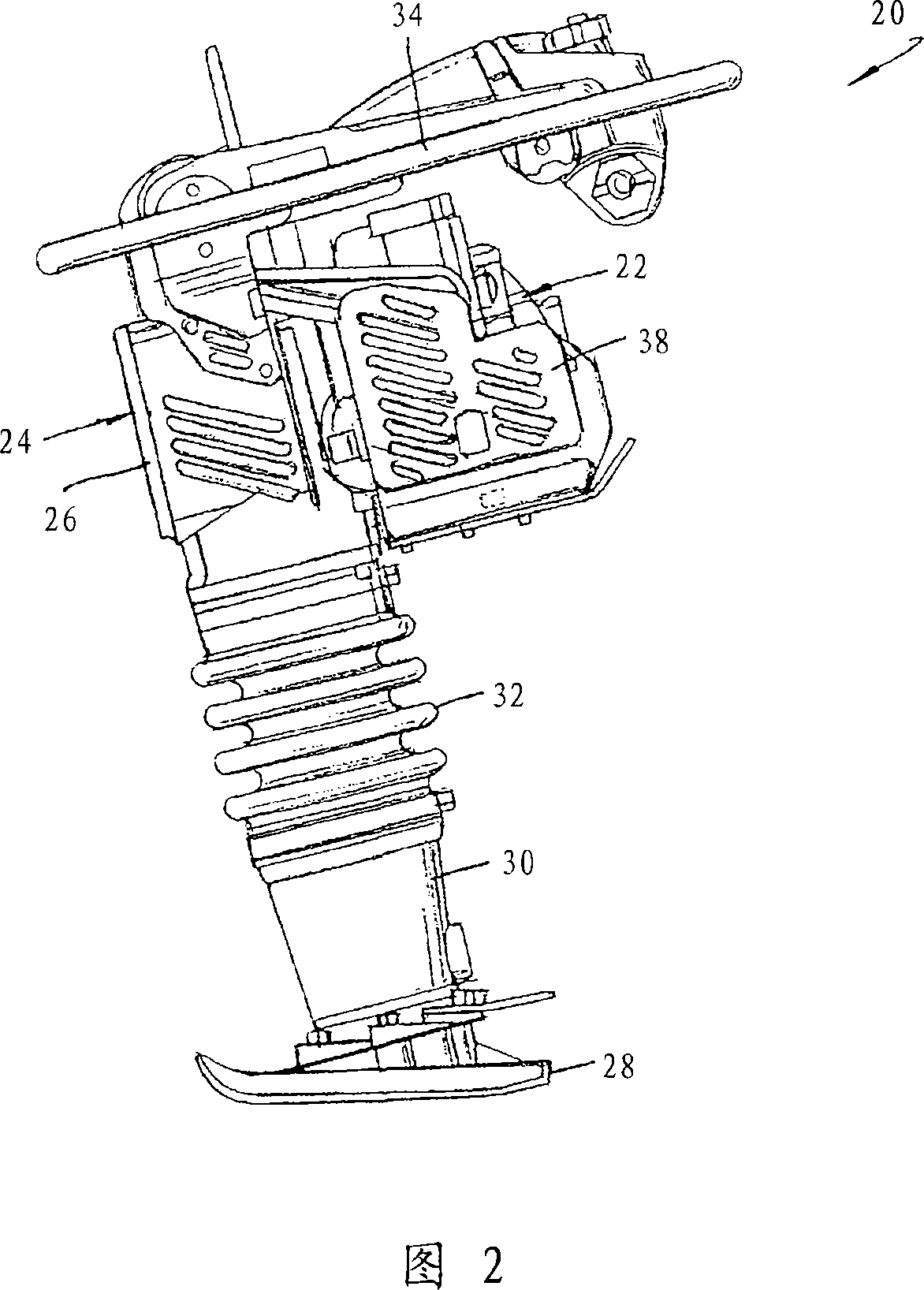

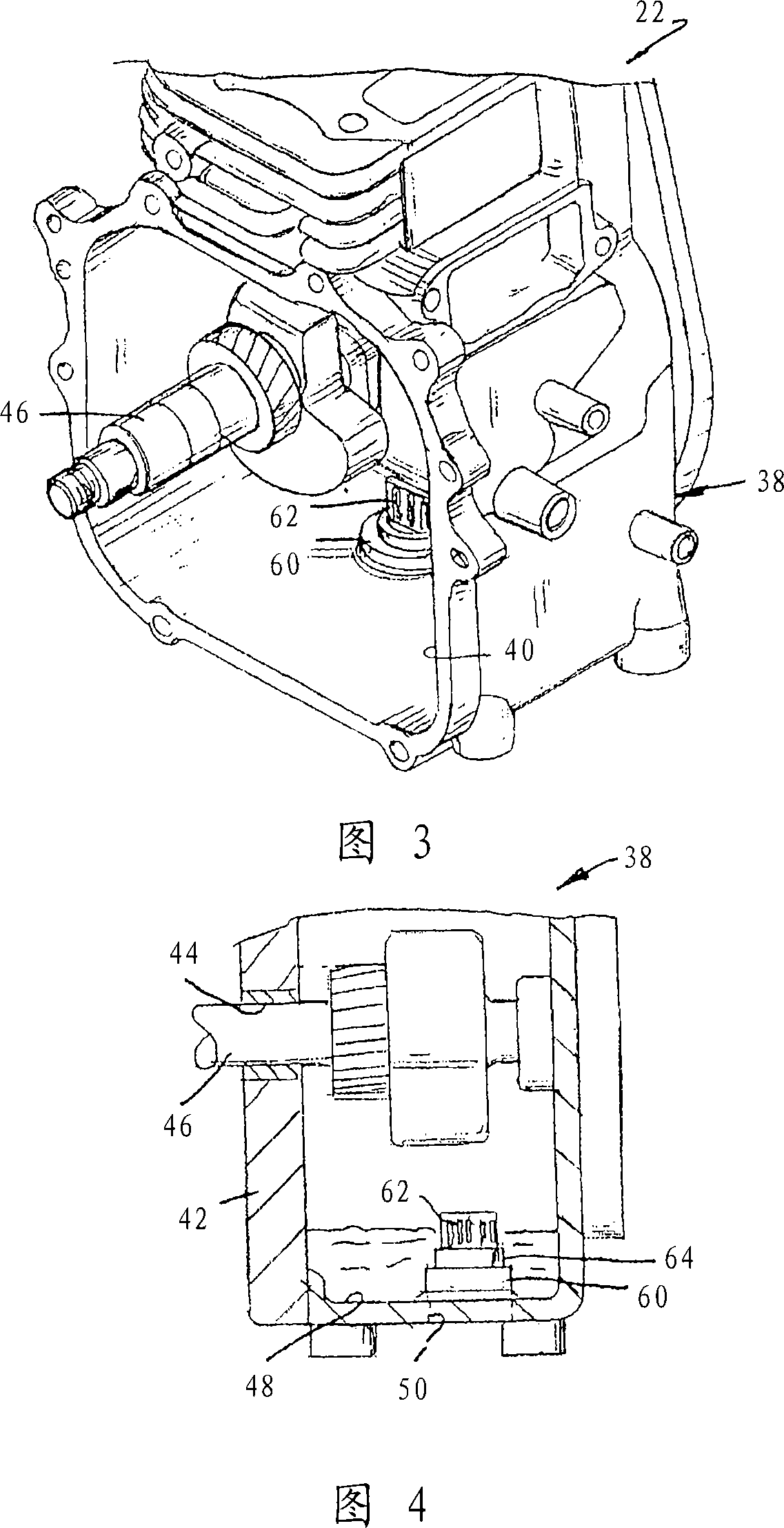

[0025] Referring now to the drawings, and initially to FIGS. 1-4 , there is shown a ram (sometimes referred to as a ram) 20 comprising a motor 22 and a ram subassembly 24 bolted to each other to form an integral unit. The ram subassembly 24 includes a ram crankcase 26 and a reciprocating tamping shoe 28 connected to the ram crankcase 26 by means of a reciprocating piston (not shown) for vertical vibration when the ram is in operation or reciprocating motion. The lower end of the piston is protected by a fixed housing 30 , while its upper end is protected by a flexible boot 32 which accommodates the movement of the base plate 28 relative t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com